Biodegradable pressure-sensitive adhesive and preparation method thereof

A technology for pressure-sensitive adhesives and biodegradation, applied in the direction of adhesives, pressure-sensitive films/sheets, grafted polymer adhesives, etc., can solve problems such as poor economy, achieve low cost, simple and easy preparation method, The effect of excellent adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

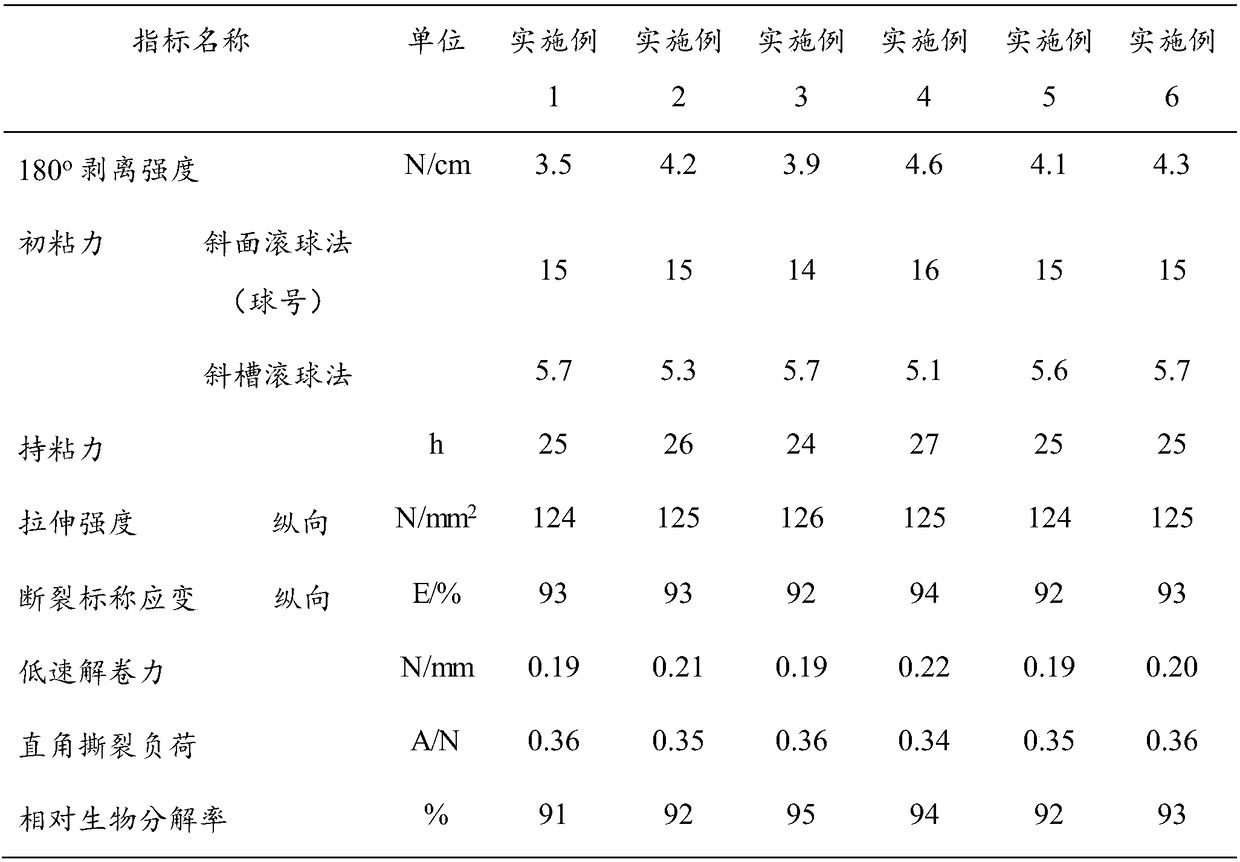

Examples

preparation example Construction

[0031] The invention provides a method for preparing a biodegradable pressure-sensitive adhesive, comprising:

[0032] A) under the action of a catalyst, the material a is reacted with the material b to obtain a polyester copolymer containing unsaturated double bonds;

[0033] Material a is selected from aliphatic alkyds and / or aliphatic lactones;

[0034] Material b is selected from unsaturated dibasic carboxylic acids or unsaturated dibasic acid anhydrides;

[0035] B) Under the action of an initiator, the polyester copolymer containing unsaturated double bonds and vinyl monomers are subjected to a free radical polymerization reaction to obtain a biodegradable pressure-sensitive adhesive.

[0036] In the present invention, the catalyst preferably includes one or more of acetate, tin compound, titanium compound and antimony compound. The acetate preferably includes one or more of zinc acetate, magnesium acetate, manganese acetate, cobalt acetate and calcium acetate. The ti...

Embodiment 1

[0063] Under nitrogen protection, 160g (1.65mol) of lactic acid with a mass concentration of 93%, 13g (0.1mol) of itaconic acid and 0.1g of stannous octoate were added to the reactor, and the oil bath was heated to 130°C for 2 hours, and then the temperature was raised React at 160°C for 2h, then raise the temperature to 180°C for 2h. The water generated during the reaction was continuously distilled off, and then the temperature was lowered to room temperature to obtain lactic acid oligomers containing unsaturated bonds. Afterwards, under nitrogen protection, 5.2g (0.05mol) styrene, 6.4g (0.05mol) butyl acrylate, 0.8g (0.0056mol) glycidyl methacrylate and 0.3g (0.0018mol) AIBN were added to the reactor , the temperature of the oil bath was raised to 65° C. for free radical polymerization, and the reaction time was 20 h. After the reaction, the biodegradable adhesive is obtained.

Embodiment 2

[0065] Under the protection of nitrogen, 160g (1.65mol) of lactic acid with a mass concentration of 93%, 12g (0.1mol) of maleic acid and 0.1g of stannous octoate were added to the reactor, and the oil bath was heated to 130°C for 2 hours, and then the temperature was raised Reaction at 180°C for 4h. The water generated during the reaction was continuously distilled off, and then the temperature was lowered to room temperature to obtain lactic acid oligomers containing unsaturated bonds. Afterwards, under nitrogen protection, 6g (0.058mol) styrene, 12g (0.065mol) isooctyl acrylate, 0.8g (0.0056mol) glycidyl methacrylate and 0.3g (0.0018mol) AIBN were added to the reactor , the temperature of the oil bath was raised to 65° C. for radical polymerization, and the reaction time was 20 h. After the reaction, the biodegradable adhesive is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Holding power | aaaaa | aaaaa |

| 180°peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com