Glass fiber and graphene hybrid filler filled polypropylene composite material and preparation method thereof

A glass fiber and composite material technology, which is applied in the field of glass fiber and graphene hybrid filler filled polypropylene composite materials, can solve the problems of limited process, difficult dispersion of antistatic agent conductive filler, large amount of addition, etc., to avoid agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

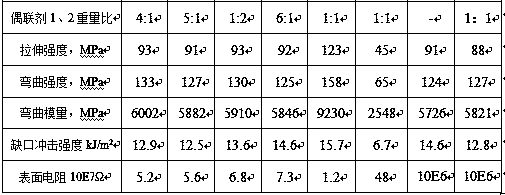

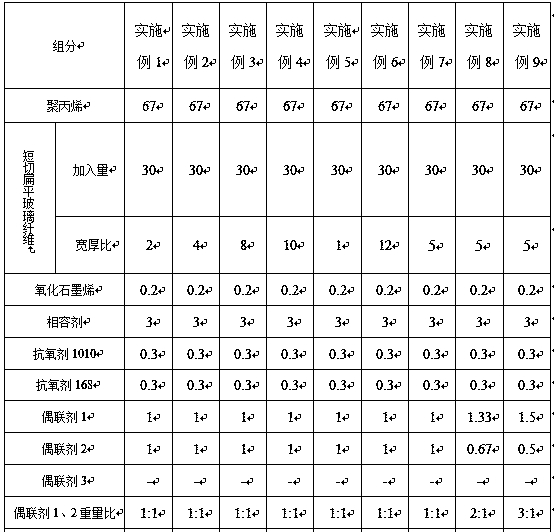

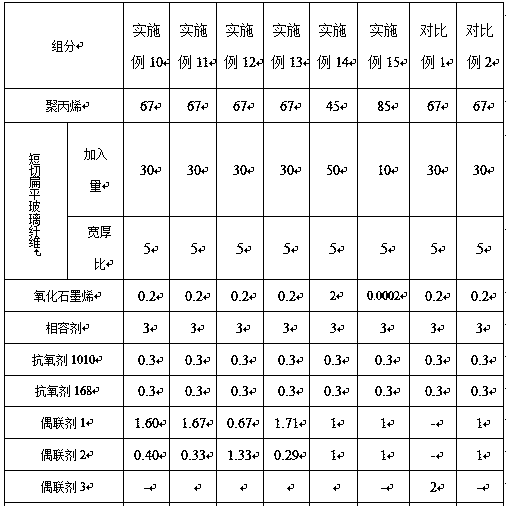

Embodiment 1-15 and comparative example 1-2

[0042] Preparation of Example 1-15 and Comparative Example 1-2 Glass Fiber and Graphene Hybrid Filler Filled Polypropylene Composite Material:

[0043]Add 10-50 parts by weight of glass fiber into deionized water according to the ratio in Table 1, and drop in 0.1-2 parts by weight of aminosilane coupling agent, wherein the aminosilane coupling agent is N-2-aminoethyl-3-ammonia Propylmethyldimethoxysilane and 3-aminopropyltriethoxysilane are mixed in a weight ratio of 1:1-5:1, mechanically stirred at room temperature for 1-48 hours, filtered, and removed Wash three times with ionic water and dry; prepare 0.0002-2 parts by weight of graphene oxide into a 0.1-2 mg / mL graphene oxide aqueous solution, and put it into the graphene oxide aqueous solution at a rate of 1-100 g / min under mechanical stirring The glass fibers after the above treatment, the positive and negative charges on the surface of the two fillers attract each other, graphene oxide is coated on the surface of the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com