A kind of UL94-5VA high flame retardant light heat aging resistance halogen-free environment-friendly flame retardant polypropylene material and preparation method thereof

A flame retardant polypropylene, high flame retardant technology, applied in the field of UL94-5VA high flame retardant light and heat aging resistance halogen-free environmentally friendly flame retardant polypropylene material and its preparation field, can solve damage, flame retardant performance decline, affect the flame retardant Combustion effect and other issues, to achieve the effects of avoiding damage, dense carbon layer, and excellent light and heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

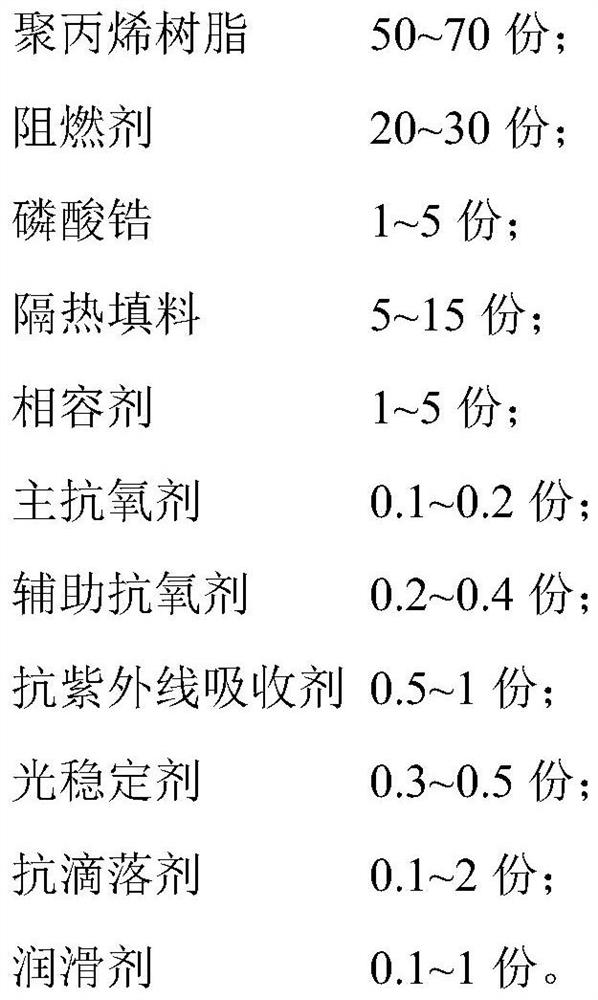

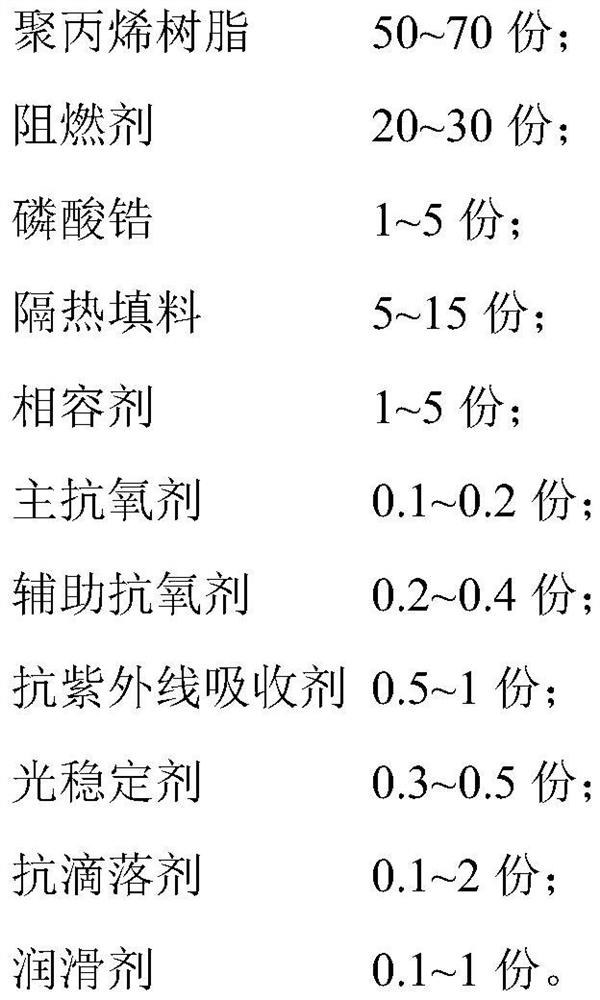

Method used

Image

Examples

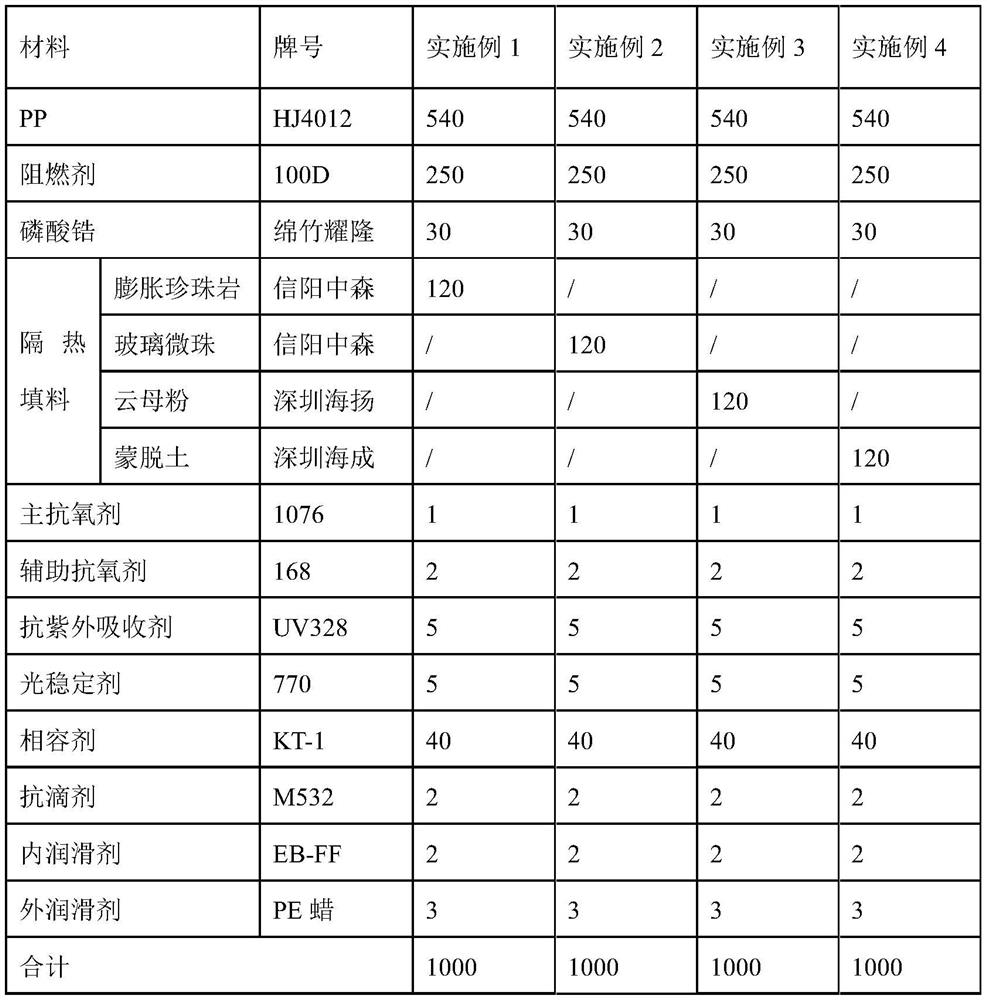

Embodiment 1

[0046] Accurately weigh 54.0% of homopolymer injection-molded polypropylene (brand HJ4012, Daehan Petrochemical) with a melt index of 12g / 10min (test standard ASTM D1238, test condition 230°C / 2.16Kg), ammonium polyphosphate expansion flame retardant ( Brand 100D, Qingyuan City Prosafefos Chemical Co., Ltd.) 25.0%, zirconium phosphate (Mianzhu Yaolong Chemical Co., Ltd.) 3.0%, expanded perlite (thermal conductivity is 0.05W / (m K), Xinyang City Zhongsen perlite Application Co., Ltd.) 12.0%, main antioxidant (brand 1076, BASF) 0.1%, auxiliary antioxidant (brand 168, BASF) 0.2%, anti-ultraviolet absorber (brand UV328, BASF) 0.5%, light stabilizer ( 770, Beijing Tiangang Auxiliary Co., Ltd.) 0.5%, external lubricant (PE wax BN-500, Qingdao Bangni Chemical Co., Ltd.) 0.3%, internal lubricant ethylene bisstearamide (EB-FF, Japan Kao ) 0.2%, pure powder type anti-dripping agent (brand M532, Japan Daikin) 0.2%, grafted maleic anhydride compatibilizer (brand KT-1, Qingdao Luwei Chemical...

Embodiment 2

[0049] The preparation method is the same as that of Example 1, except that the thermal insulation filler is replaced by hollow glass microspheres (average particle size: 11 μm, Xinyang Zhongsen Perlite Application Co., Ltd.) from expanded perlite.

Embodiment 3

[0051] The preparation method is the same as that of Example 1, except that the thermal insulation filler is replaced by mica powder (diameter-thickness ratio: 105, mesh: Shenzhen Haiyang Powder Technology Co., Ltd.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com