Electrochromic solution capable of being gelatinized and self-repaired under illumination, and application thereof

An electrochromic and gelling technology, which is applied in the fields of color-changing fluorescent materials, optics, nonlinear optics, etc., can solve the problems of hard to repair gel cracks, increase the complexity of the process, and limit the gelling ability of solutions, and achieve extended Service life, effect of inhibiting phase separation or deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

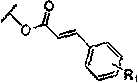

[0057] Use cinnamoyl chloride and excess butanediol as raw materials, pyridine as hydrochloric acid absorbent, react at room temperature for 2 hours (the reaction formula is shown in the following formula), add ethyl acetate after the reaction, and then wash with water for 3 times, and the organic phase is passed through The solvent was distilled off under reduced pressure to obtain the compound represented by structural formula 1.

[0058]

[0059] The compound represented by structural formula 1 is mixed with 4,4',4''-triphenylmethane triisocyanate, hexamethylene diisocyanate, butanediol, trace organotin catalyst dibutyltin dilaurate, 1,1'- Dineopentyl-4,4'-bipyridine bis(hexafluoroborate) and 5,10-diisopropyl-5,10-dimethylphenazine were dissolved in propylene carbonate to form an electrogenic Color-changing solution (the concentration of the compound represented by structural formula 1 is 10 mmol / L; the concentration of 4,4',4''-triphenylmethane triisocyanate is 20 mmol / ...

Embodiment 2

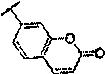

[0062] Using the atom transfer radical polymerization method, the coumarin-type styrene shown in the structural formula 2 (the compound shown in the structural formula 2) and methoxyethyl acrylate (the molar ratio is 1:4) are polymerized monomers, and the 2- Ethyl bromopropionate was used as an initiator, and CuCl / Me10TATD was used as a catalyst to react in a dioxane solvent at 60°C for 24 hours to obtain a polymer represented by structural formula 3.

[0063]

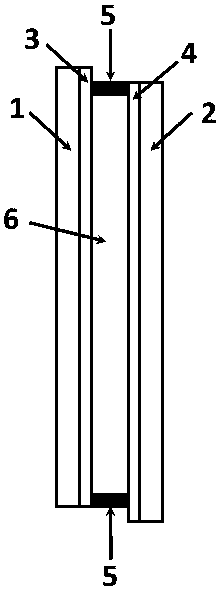

[0064] The polymer represented by structural formula 3, 1,1'-dihexyl-4,4'-bipyridine bis(trifluoromethanesulfonate) and 5,10-dihydro-5,10-dimethylphenazine Dissolve in butyrolactone to form an electrochromic solution (the concentration of the compound shown in structural formula 3 is 5% (w / v); 1,1'-dihexyl-4,4'-bipyridine bis(trifluoro mesylate) at a concentration of 50 mmol / L; 5,10-dihydro-5,10-dimethylphenazine at a concentration of 50 mmol / L;), perfused in such as figure 1 In the shown electrochromic device, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com