Preparation method of microsphere cavity laser based on ultra-strong up-conversion multi-component glass material

A glass material and multi-component technology, which is applied in the field of microsphere cavity laser preparation based on super-strong up-conversion multi-component glass materials, can solve the problems of low luminous efficiency, achieve high heating efficiency, short heating time, and solve the problem of output low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

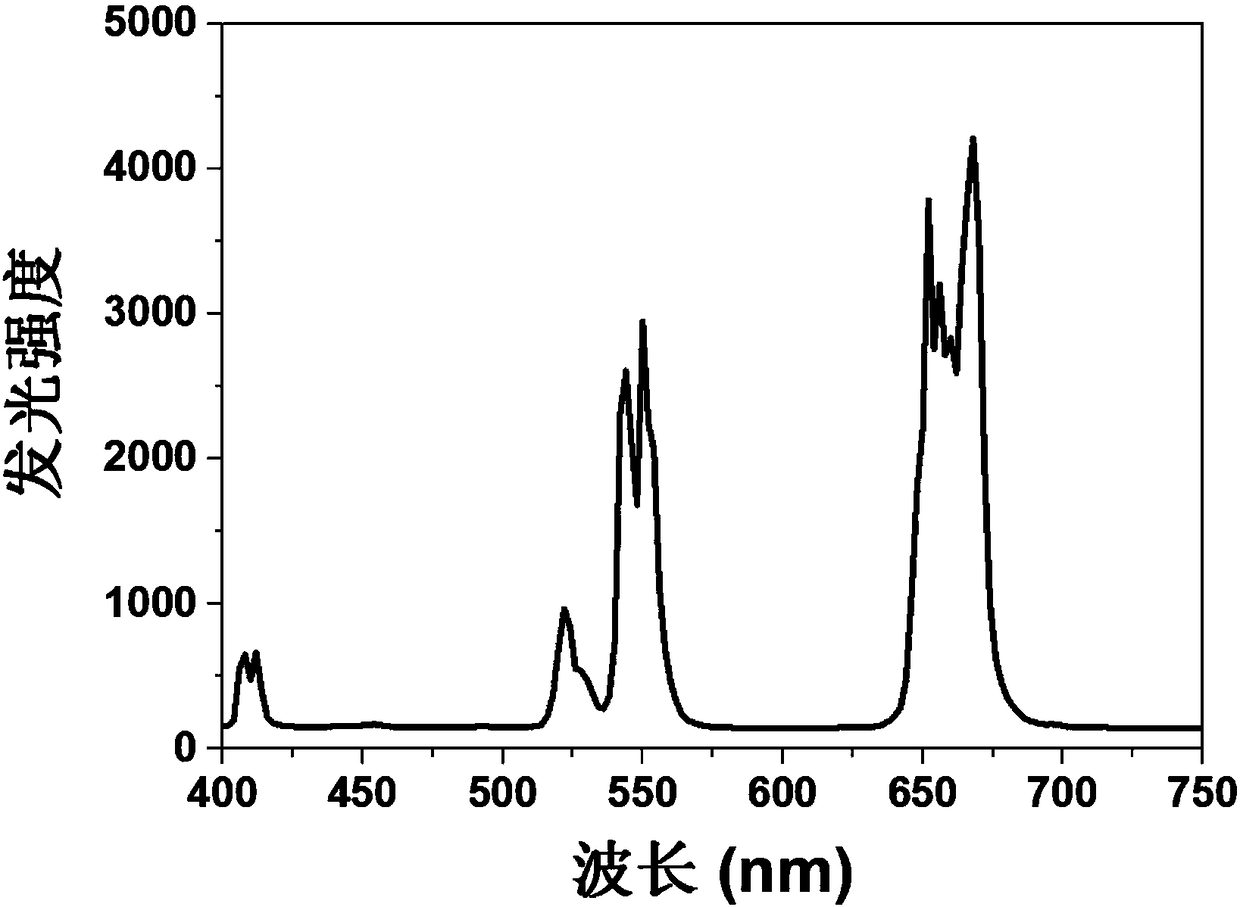

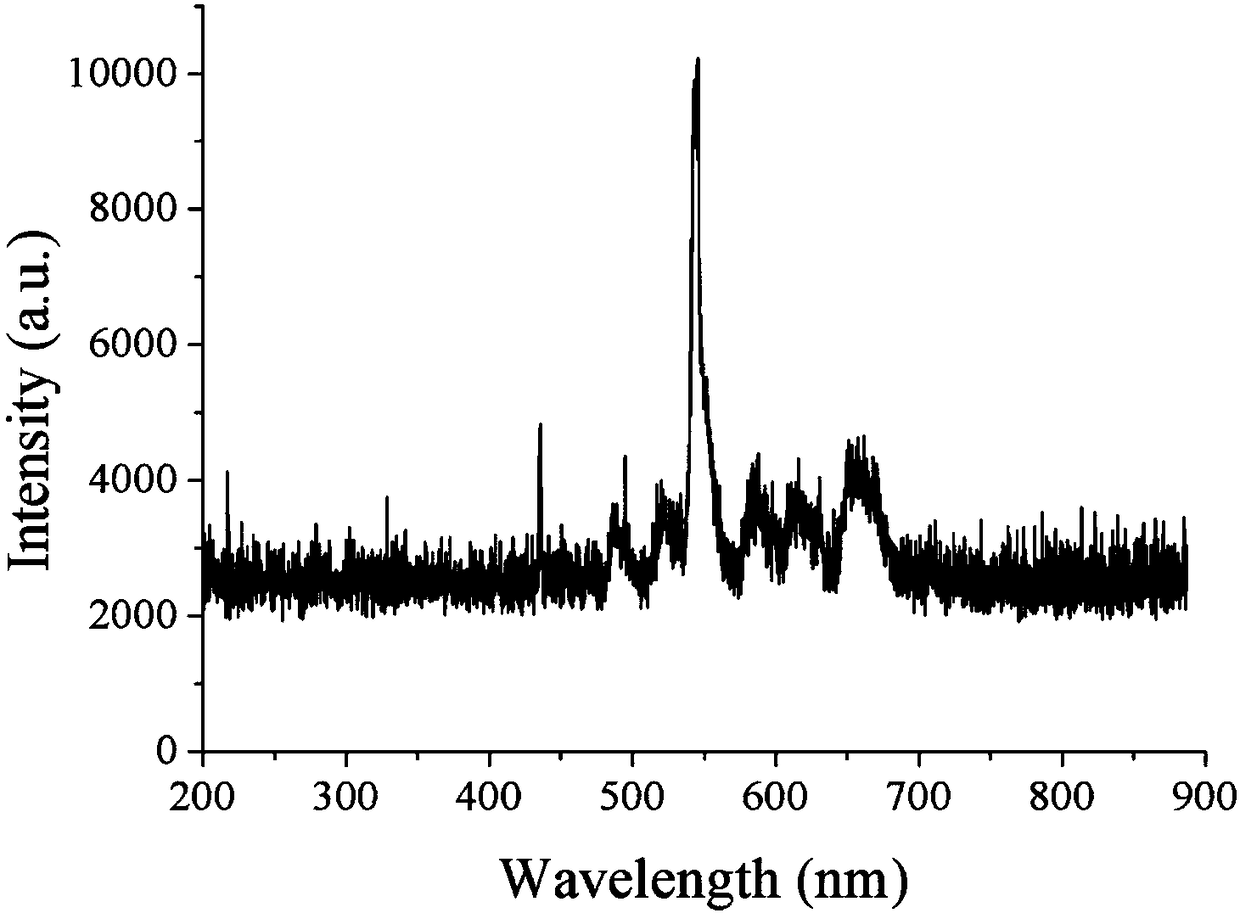

[0045] The preparation method of the microsphere cavity laser based on the ultra-intensive up-conversion multi-component glass material includes the preparation of matrix glass, the doping of rare earth ions, the preparation of glass microspheres, the coupling of pump light and the emission of narrow linewidth laser. The mole percentage of each raw material of the glass matrix used is 70SiO 2 -15KF-15ZnF 2 .The dopant ion concentration is 1.5YbF 3 -0.1Er 2 o 3 .

[0046]The preparation process of the microcavity laser includes the following steps of glass preparation and microsphere preparation:

[0047] Weigh the high-purity raw materials according to a certain ratio, and put them in the ball mill to stir, so that all kinds of raw materials are fully mixed;

[0048] Then put the mixture into a platinum crucible and place it in a high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com