Coating sustained-release material, preparation method thereof and coated slow-release fertilizer prepared by using coating sustained-release material

A coating slow-release and fertilizer technology, which is applied in the direction of layered/coated fertilizers, phosphate fertilizers, fertilization devices, etc., can solve the problems of large environmental impact and high temperature requirements, and achieve process energy saving, good slow-release performance, and extended The effect of the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

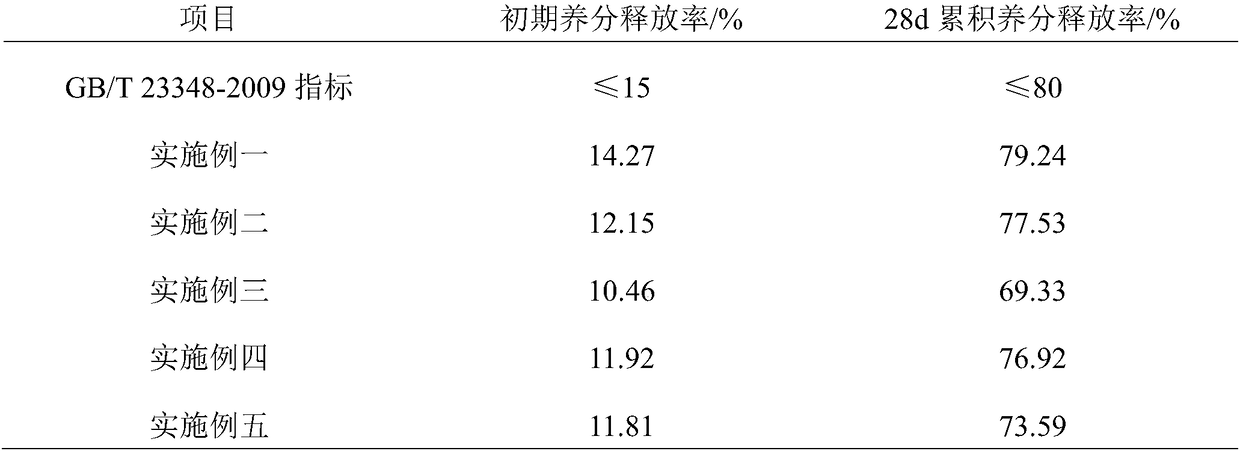

Examples

Embodiment 1

[0035] A kind of preparation of coated slow-release material, concrete steps are as follows:

[0036] 1) Fully stir 40g of polyethylene glycol solution with a mass concentration of 2.5% and 3g of vinyl acetate-ethylene copolymer emulsion (Guangxi Guangwei GW-705) to completely dissolve the vinyl acetate-ethylene copolymer emulsion;

[0037] 2) Add 0.2 g of carboxymethylcellulose sodium salt to the solution obtained in step 1) and stir fully to dissolve it completely;

[0038] 3) Add 0.8 g of glycerol to the solution obtained in step 2), and stir and mix for 15 min at a stirring speed of 950 rpm;

[0039] 4) Add 5 g of silicon dioxide and 0.1 g of aluminum phosphate to the solution obtained in step 3), and stir at a stirring speed of 950 rpm for 35 min to obtain a coating liquid, namely a coating slow-release material.

[0040] The coated slow-release material prepared in this embodiment is used to prepare coated slow-release fertilizer, and the specific steps are as follows: ...

Embodiment 2

[0046] A kind of preparation of coated slow-release material, concrete steps are as follows:

[0047] 1) Fully stir 40g of polyethylene glycol solution with a mass concentration of 5% and 2g of vinyl acetate-ethylene copolymer emulsion (Guangxi Guangwei GW-705) to completely dissolve the vinyl acetate-ethylene copolymer emulsion,

[0048] 2) Add 0.4 g of carboxymethylcellulose sodium salt to the solution obtained in step 1) and stir well to completely dissolve it.

[0049] 3) Add 0.5 g of glycerol and 0.1 g of ethylene glycol to the solution obtained in step 2) and stir and mix for 15 min at a stirring speed of 894 rpm,

[0050] 4) Add 3 g of silicon dioxide and 0.2 g of aluminum phosphate to the solution obtained in step 3) and stir at a stirring speed of 894 rpm for 35 min to obtain a coating solution.

[0051] The coated slow-release material prepared in this embodiment is used to prepare coated slow-release fertilizer, and the specific steps are as follows:

[0052] Select...

Embodiment 3

[0054] A kind of preparation of coated slow-release material, concrete steps are as follows:

[0055] 1) Fully stir 40g of polyethylene glycol solution with a mass concentration of 7.5% and 1g of vinyl acetate-ethylene copolymer emulsion (Guangxi Guangwei GW-705) to completely dissolve the vinyl acetate-ethylene copolymer emulsion,

[0056] 2) Add 0.6 g of carboxymethylcellulose sodium salt to the solution obtained in step 1) and stir well to completely dissolve it.

[0057] 3) Add 0.4 g of glycerol to the solution obtained in step 2) and stir and mix for 15 min at a stirring speed of 1012 rpm,

[0058] 4) Add 4 g of silicon dioxide and 0.3 g of aluminum phosphate to the solution obtained in step 3) and stir at a stirring speed of 1012 rpm for 35 min to obtain a coating solution.

[0059] The coated slow-release material prepared in this embodiment is used to prepare coated slow-release fertilizer, and the specific steps are as follows:

[0060] Select 5g of diammonium phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com