Preparation method and application of carboxylated polystyrene microspheres

A polystyrene microsphere, carboxylation technology, applied in the direction of microsphere preparation, biochemical equipment and methods, microcapsule preparation, etc., can solve the problems of not being suitable for liquid phase chips, small particle size of microspheres, etc., and achieve high yield High, improved dispersion, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a kind of preparation method of carboxylated polystyrene microspheres, comprising:

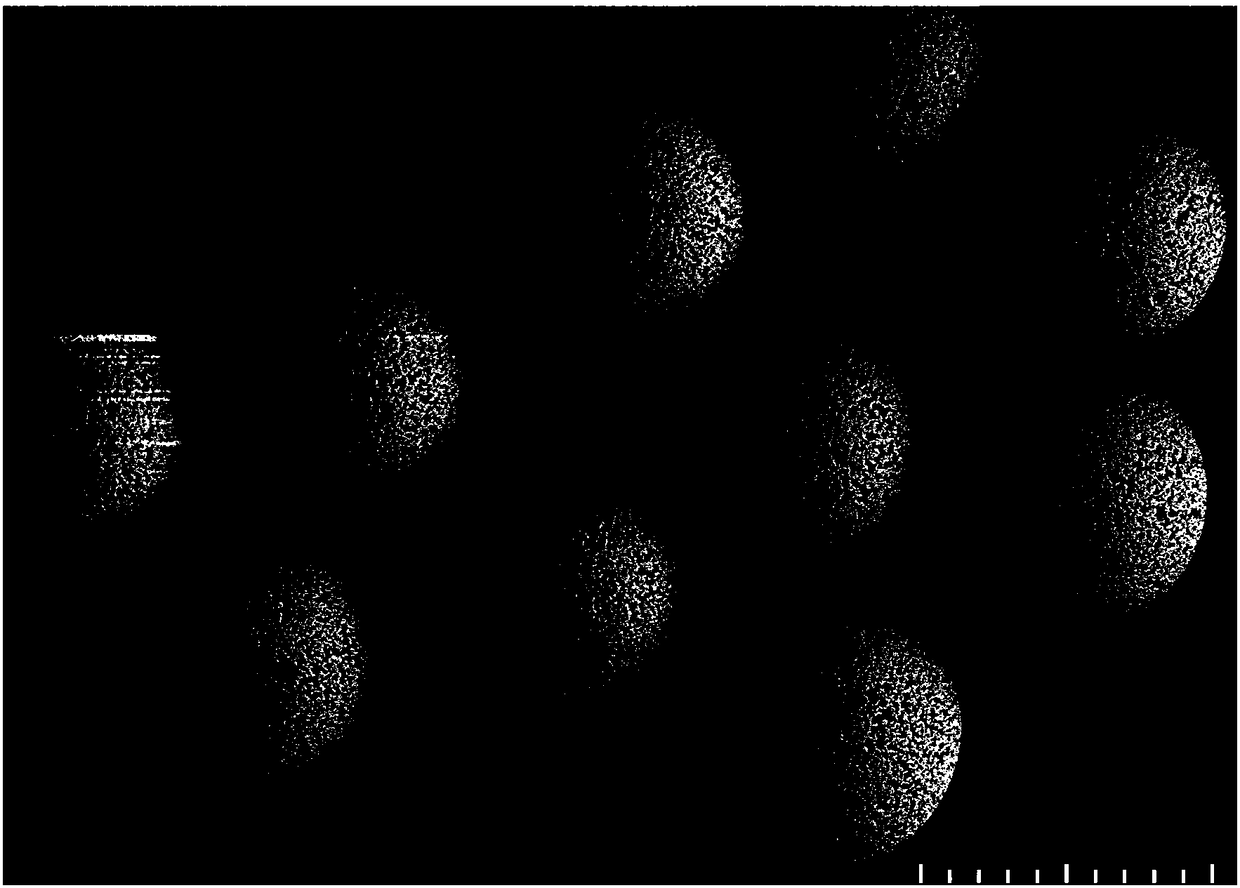

[0031] Dissolve 1.5g of dispersant polyvinylpyrrolidone in 27.2g of ethanol and 18.1g of ethylene glycol monomethyl ether, stir at a speed of 200 rpm, then add 0.136g of methacrylic acid and 1wt% azobisiso 13.6 g of styrene butyronitrile was reacted at 45° C. for 20 minutes and then at 70° C. for 24 hours under a nitrogen atmosphere. After the reaction, cool to room temperature, take the solid, wash and dry to obtain carboxylated polystyrene microspheres. The yield of this example is 96%, the particle size of the obtained carboxylated polystyrene microspheres is 9 μm, and the dispersion coefficient is 0.011. The SEM image of the carboxylated polystyrene microspheres that the present embodiment obtains is as follows figure 1 .

Embodiment 2

[0033] This embodiment provides a kind of preparation method of carboxylated polystyrene microspheres, comprising:

[0034] Dissolve 1.5g of dispersant polyvinylpyrrolidone in 27.2g of ethanol and 18.1g of ethylene glycol monomethyl ether, stir at a speed of 200 rpm, then add 0.136g of methacrylic acid and 1wt% azobisiso 13.6 g of styrene butyronitrile was first reacted at 50° C. for 10 minutes in a nitrogen atmosphere, and then reacted at 80° C. for 20 hours. After the reaction, cool to room temperature, take the solid, wash and dry to obtain carboxylated polystyrene microspheres. The yield of this example is 93%, the average particle diameter of the obtained carboxylated polystyrene microspheres is 8.5 μm, and the dispersion coefficient is 0.015.

Embodiment 3

[0036] Dissolve 1.5g of dispersant polyvinylpyrrolidone in 27.2g of ethanol and 18.1g of ethylene glycol monomethyl ether, stir at a speed of 200 rpm, then add 0.136g of methacrylic acid and 1wt% azobisiso 13.6 g of styrene butyronitrile was first reacted at 55° C. for 5 minutes, and then reacted at 80° C. for 36 hours under a nitrogen atmosphere. After the reaction, cool to room temperature, take the solid, wash and dry to obtain carboxylated polystyrene microspheres. The yield of this example is 96%, the average particle diameter of the obtained carboxylated polystyrene microspheres is 9.5 μm, and the dispersion coefficient is 0.023.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com