Method and device for preparing flexible battery negative electrode powder

A conductive powder, carbon powder technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of easily hydrolyzed battery corrosion inhibition system, instability, etc., to improve self-discharge phenomenon, easy operation, and improve storage life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

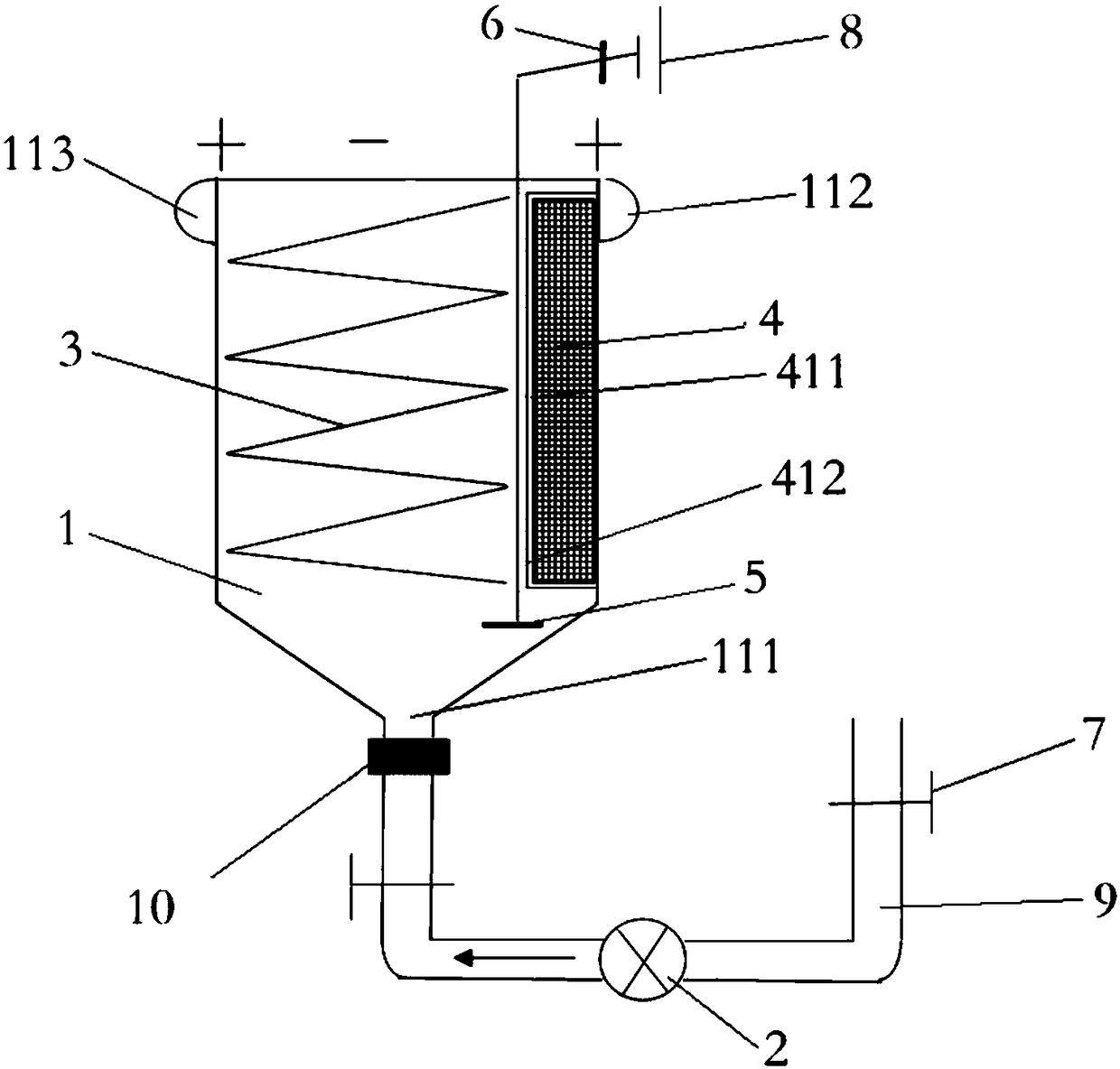

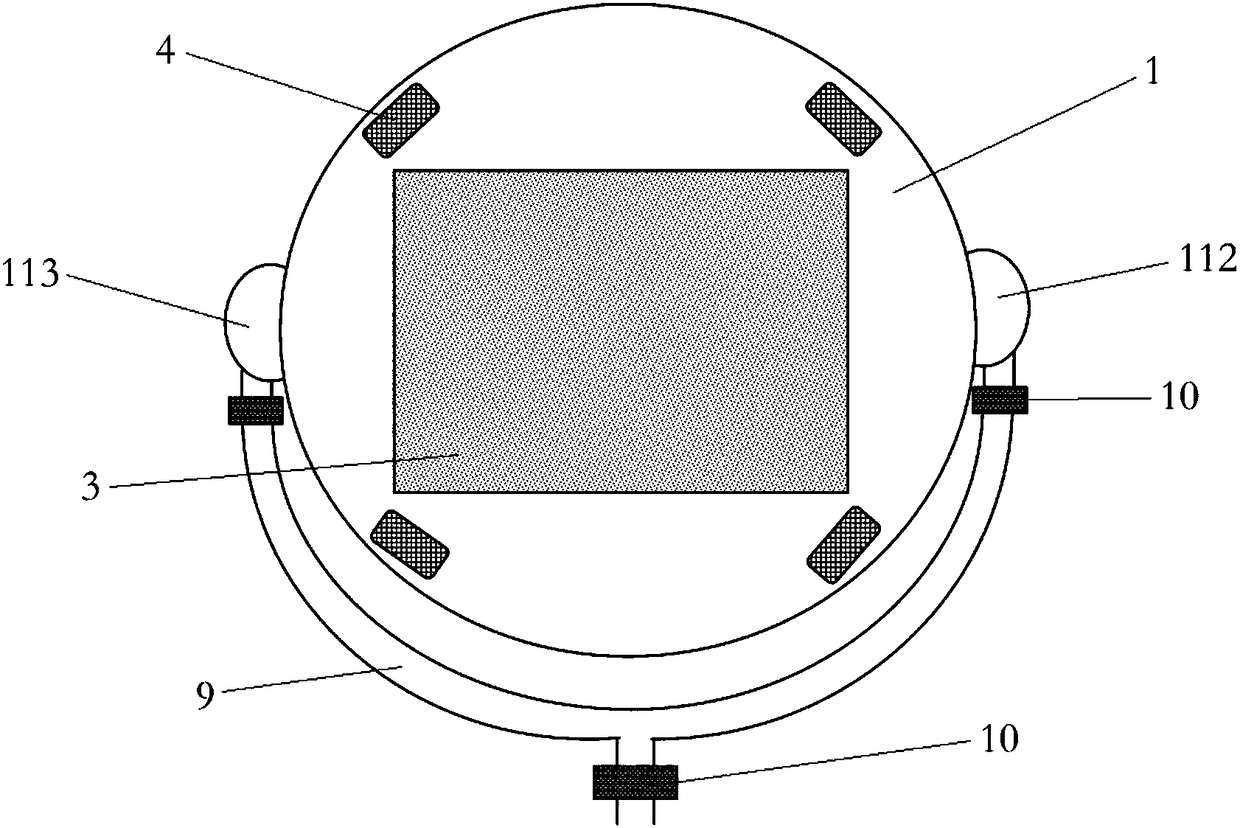

Method used

Image

Examples

Embodiment 1

[0032] The conductive powder is zinc powder, and the zinc-indium alloy powder is prepared. The size of zinc powder is 100um, and the shape can be spherical.

[0033] Pre-plating treatment:

[0034] Degreasing; cleaning; activation; DC or pulse intermittent tinning.

[0035] Electroplating solution and operating conditions: indium sulfate 10g / L, zinc sulfate 50g / L, cationic surfactant cetyltetramethylammonium bromide 4g / L, slowly add zinc powder, stir until uniform dispersion, adjust the pH value 3. Add the mixed plating solution into the plating tank, turn on the circulation and stir, electroplate at room temperature, adjust the cathode current density to 3A / dm2, and the electroplating time to 20min.

[0036] Post-plating treatment:

[0037] A: Indium-plated zinc powder washing treatment: filter the obtained plating solution, recover the filtrate for the next electroplating, and clean the filter cake with deionized water until it is clean;

[0038] B: Drying treatment of i...

Embodiment 2

[0042] The conductive powder is zinc powder, and the zinc-indium alloy powder is prepared. The size of zinc powder is 10um, and the shape can be spherical. The difference from Example 1 is:

[0043] DC or pulse intermittent electroplating indium.

[0044] Electroplating solution and operating conditions: indium sulfate 15g / L, ammonium sulfate 10g / L, cationic surfactant cetyltetramethylammonium bromide 2g / L, slowly add zinc powder with a size of 10um, stir until uniformly dispersed, Adjust the PH value to 4, add the mixed plating solution into the plating tank, start the circulation and stir, electroplate at room temperature, adjust the cathode current density to 1A / dm2, and the electroplating time to 30min.

[0045] The post-plating washing and drying treatments were the same as in Example 1 to obtain a zinc-indium alloy composite powder.

Embodiment 3

[0047]The conductive powder is zinc powder, and the zinc-tin alloy powder is prepared. The size of the zinc powder is 20um, and the shape is spherical. The difference from Example 1 is:

[0048] DC or pulse intermittent electroplating of bismuth.

[0049] Plating solution and operating conditions: stannous sulfate 60g / L, citric acid 45g / L, ammonium bifluoride 60g / L, cationic surfactant cetyltetramethylammonium bromide 5g / L, slowly add zinc powder, stir until Disperse uniformly, adjust the pH value to 5, add the mixed plating solution into the plating tank, start the circulation and stir, electroplate at room temperature, adjust the cathode current density to 3A / dm2, and the electroplating time to 60min.

[0050] The post-plating washing and drying treatments were the same as in Example 1 to obtain a zinc-tin composite gold powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com