Two-channel advanced oxidation apparatus and flue gas purification system using two-channel advanced oxidation apparatus

A flue gas purification system and advanced oxidation technology, applied in the field of flue gas purification and treatment, can solve the problems of low nitrogen oxide removal efficiency, large ozone consumption, and high operating costs, so as to reduce operating costs, improve reaction efficiency, and speed up The effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

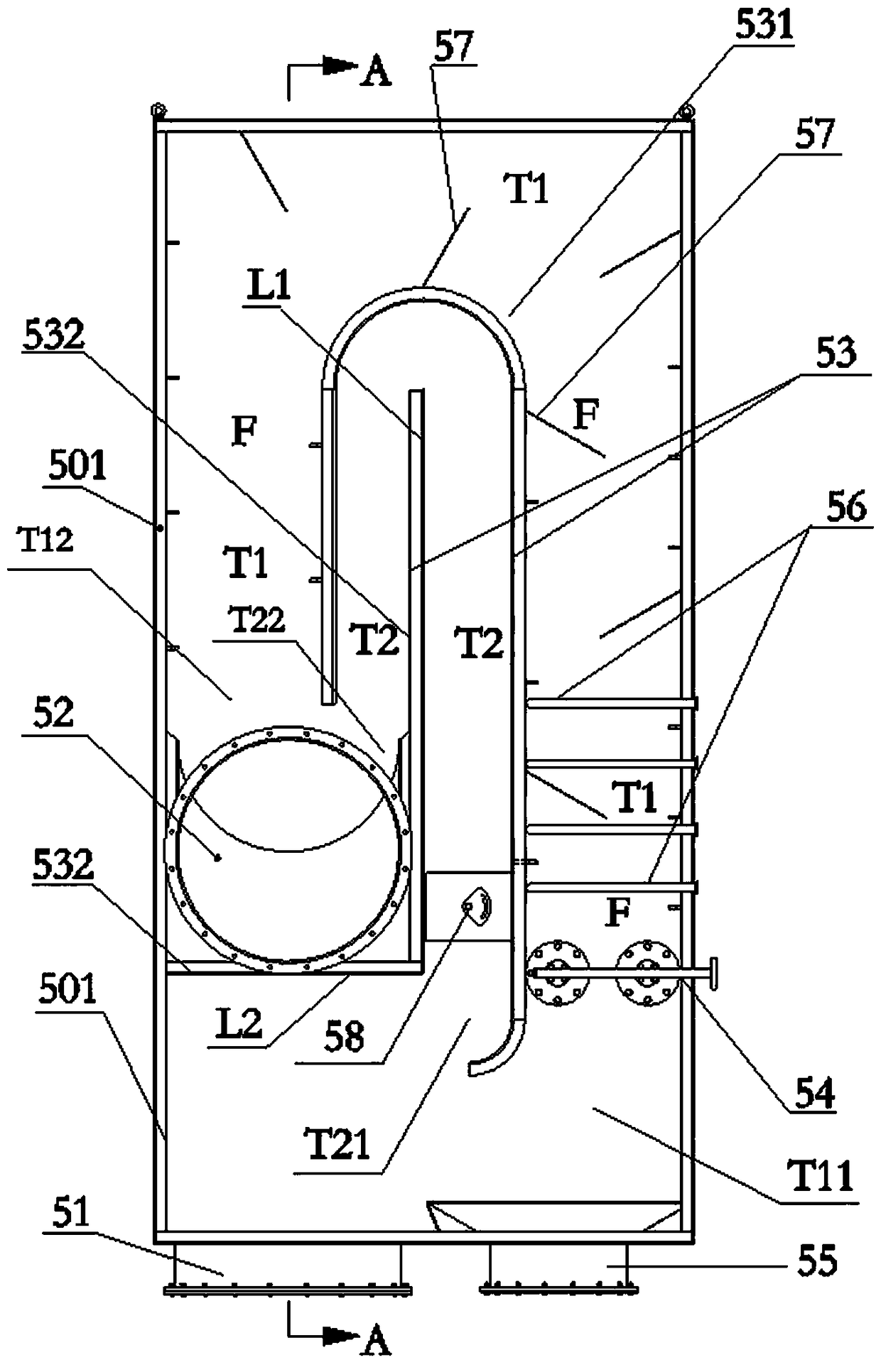

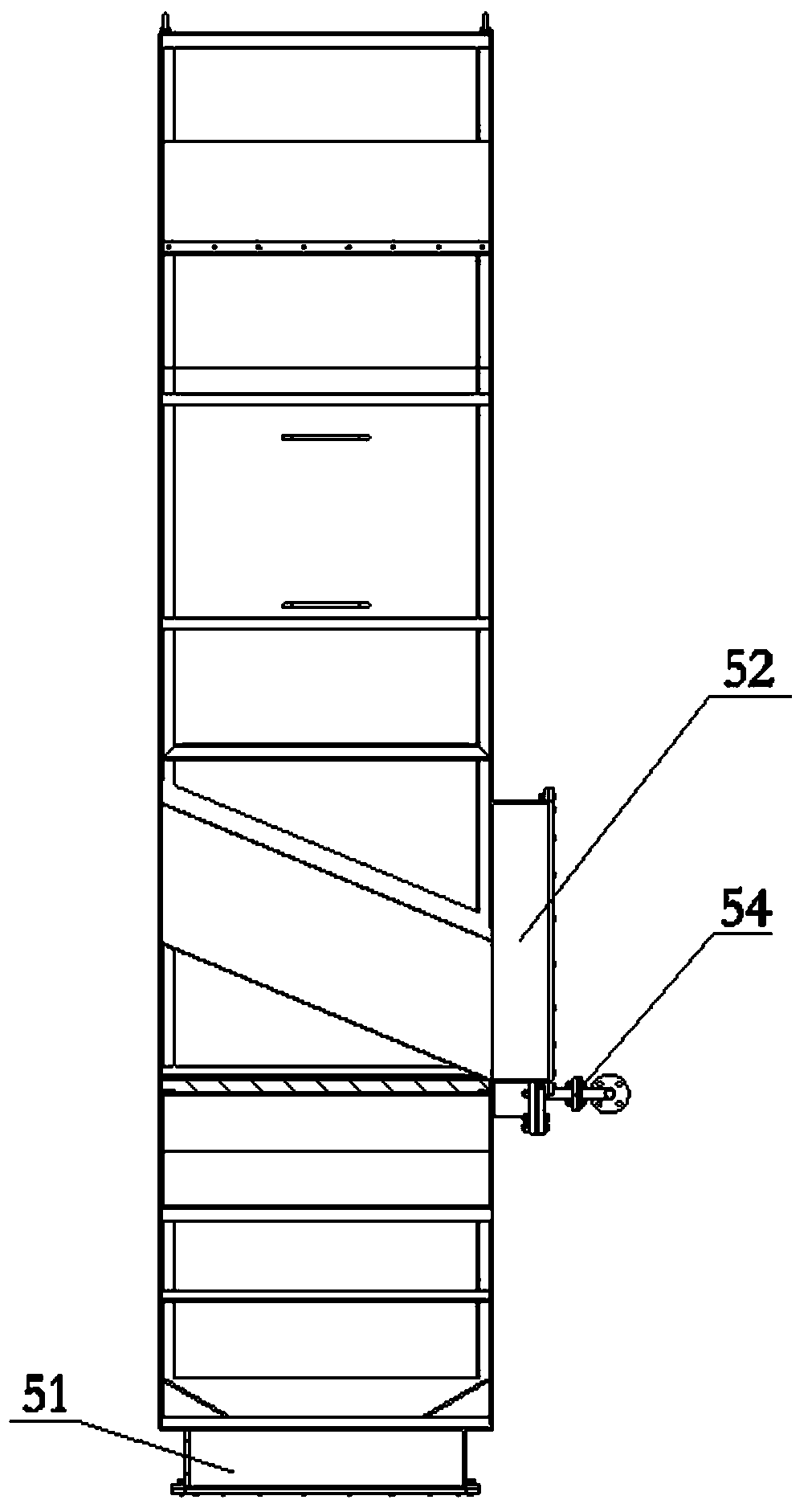

[0052] Such as Figure 1-4 As shown, the first embodiment is an embodiment of the dual-channel advanced oxidation device of the first object of the present invention.

[0053] Such as Figure 1-4 As shown, a dual-channel advanced oxidation device 5 according to the first object of the present invention includes a body 501 on which a gas inlet 51, a first gas outlet 52, an oxidant addition port 54 and a sewage outlet 55 are arranged. There is a gas channel partition 53. In this embodiment, the gas channel partition 53 includes a first partition 531 and a second partition 532. The first partition 531 is a curved plate with a U-shaped bend, so The second dividing plate 532 is an L-shaped plate, the first dividing plate 531 and the second dividing plate 532 partially overlap each other, and the vertical edge L1 of the second dividing plate 532 extends into the U-shaped bending portion of the first dividing plate 531. There is a distance between the top and the top of the U-shape...

Embodiment 2

[0060] Such as Figure 5 As shown, the second embodiment is an embodiment of the flue gas purification system of the dual-channel advanced oxidation device for the application of the first purpose described in the technical solution of the second purpose of the present invention.

[0061] A flue gas purification system using a dual-channel advanced oxidation device, including a flue gas output device 1, a heat recovery device 2, a dust removal device 3, an oxidant dosing device 4, an advanced oxidation device 5, a purification and removal reaction device 6, a removal An agent supply device 7 and an exhaust device 8; the advanced oxidation device 5 is the advanced oxidation device described in the technical solution 1 of the present invention, the air inlet 21 of the heat recovery device is connected with the flue gas output device 1, and the heat recovery device The gas outlet 22 is connected with the air inlet 31 of the dedusting device, the gas outlet 32 of the dedusting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com