Method for depositing high-quality diamond coating on inner wall of tubular workpiece

A diamond coating, high-quality technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as low electron concentration, low atomic hydrogen concentration, pollution, etc., to eliminate the existence of graphite phase , The effect of uniform plasma density and axial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

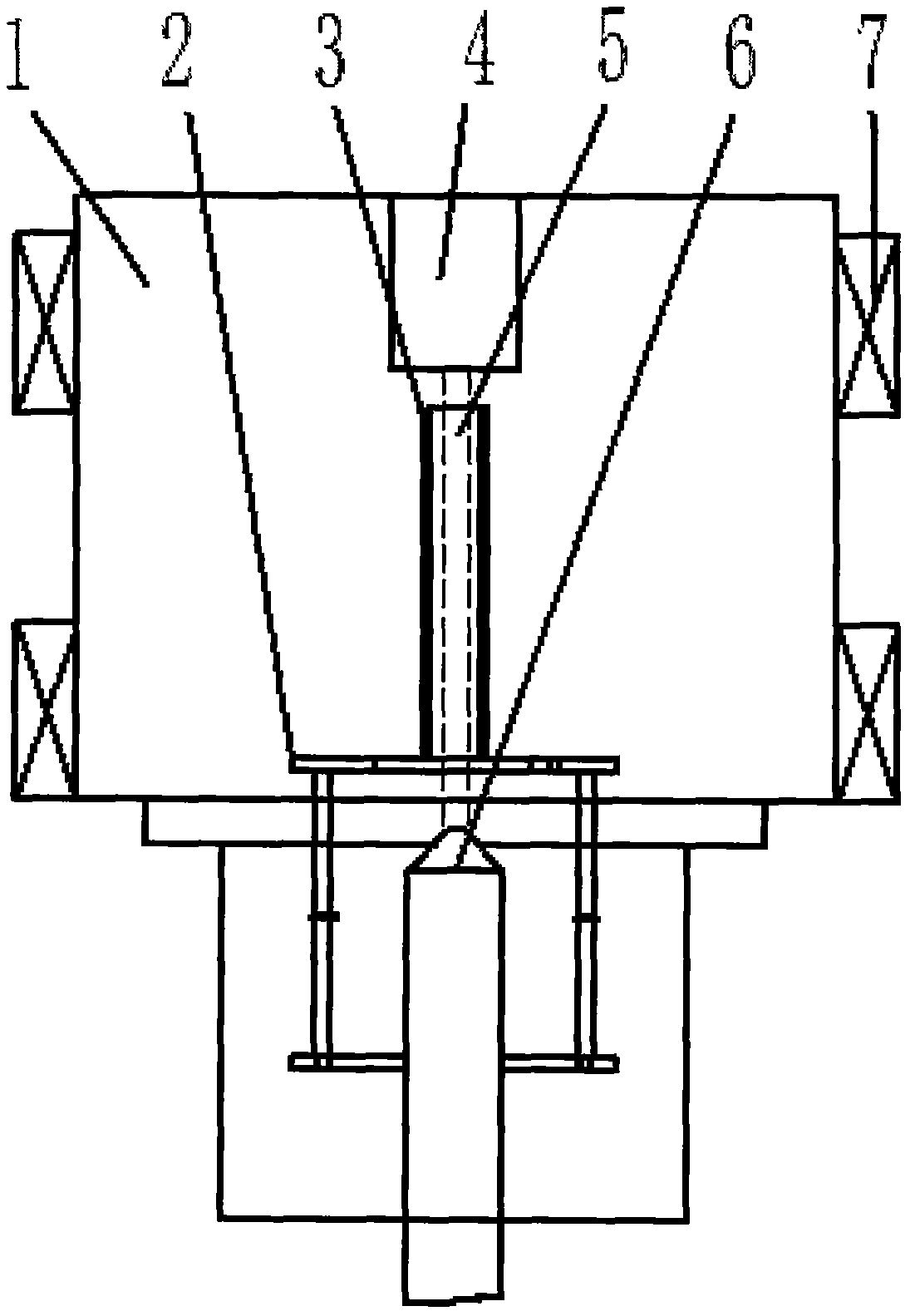

[0026] The strong DC arc stretching plasma chemical vapor deposition device for depositing high-quality diamond coating on the inner wall of the tubular workpiece includes: vacuum chamber 1, ceramic workpiece holder 2, tubular workpiece 3, anode 4, plasma column 5, cathode 6, and electromagnetic coil 7 Composition of diamond deposition system. Wherein, the tubular workpiece 3 is a molybdenum tube with an inner diameter of 100 mm, a wall thickness of 3 mm, and a length of 600 mm. The ceramic workpiece holder 2 positions the tubular workpiece 3 at the center of the vacuum chamber 1 and plays the role of insulating the tubular workpiece 3 and the vacuum chamber 1 . The cathode 6 is located at the center of the top of the vacuum chamber 1 , and the anode 4 is located at the center of the bottom of the vacuum chamber 1 . The ceramic workpiece holder 3 can rotate to ensure the uniformity of diamond coating deposition. The electromagnetic coil 7 is divided into upper and lower grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com