Method for preparing strained silicon by scanning-type high-energy microbeam X-ray

An X-ray and strained silicon technology, which is applied in the field of scanning high-energy micro-beam X-ray preparation of strained silicon, can solve the problems of increasing the yield and reliability of the strain process module circuit, and improving the difficulty of the integrated circuit process, and achieves the exposure time. Short, simplified production process, fast strain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further introduced below with reference to the accompanying drawings and specific embodiments of the description.

[0018] The first embodiment specifically includes the following steps:

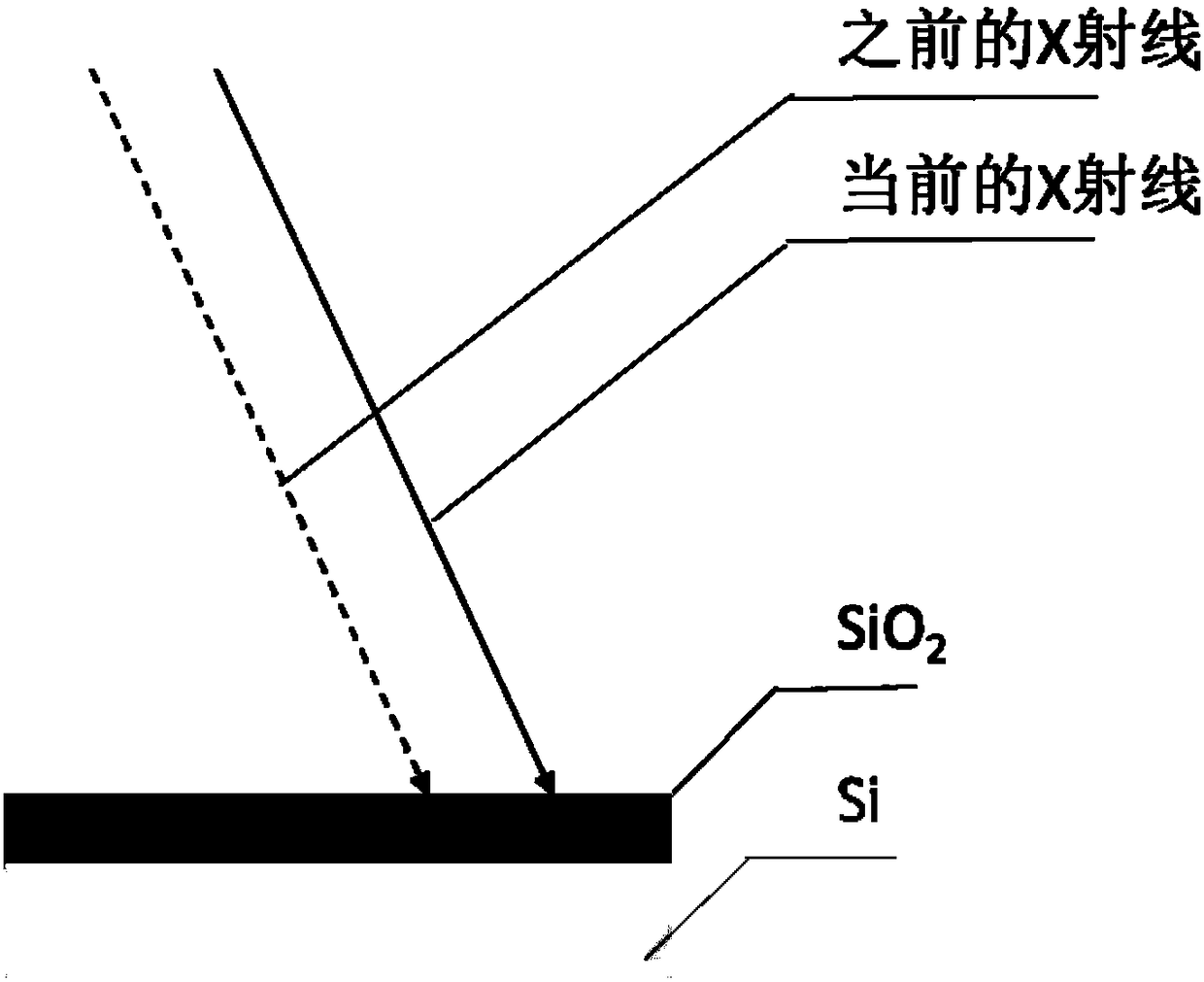

[0019] Step (1) synthesize a Si / SiO2 double-layer composite structure system, adopt the well-known dry oxygen oxidation method to synthesize, such as figure 1 As shown, its structure is a silicon film covered with a silicon dioxide layer on the upper surface, the thickness of the silicon film is 2 μm, the thickness of the silicon dioxide layer is 0.45 μm, and the size is 4.7 mm × 4.7 mm, in which the Si / SiO2 double-layer composite structure system , the details of the synthesis process are as follows:

[0020] Take an 8-inch N-type low-resistance double-sided polished silicon wafer, perform standard cleaning on the silicon wafer, remove the surface oxide layer with HF (1:100), and dry it with nitrogen to complete the preparation. The wafer was slowly p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com