Direct activation method of lithium air battery of organic electrolyte system

A lithium-air battery, organic electrolyte technology, applied in electrical components, secondary batteries, electrochemical generators, etc., can solve problems such as easy access to batteries, unknown impact on cycle stability of lithium-air batteries, metal lithium corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

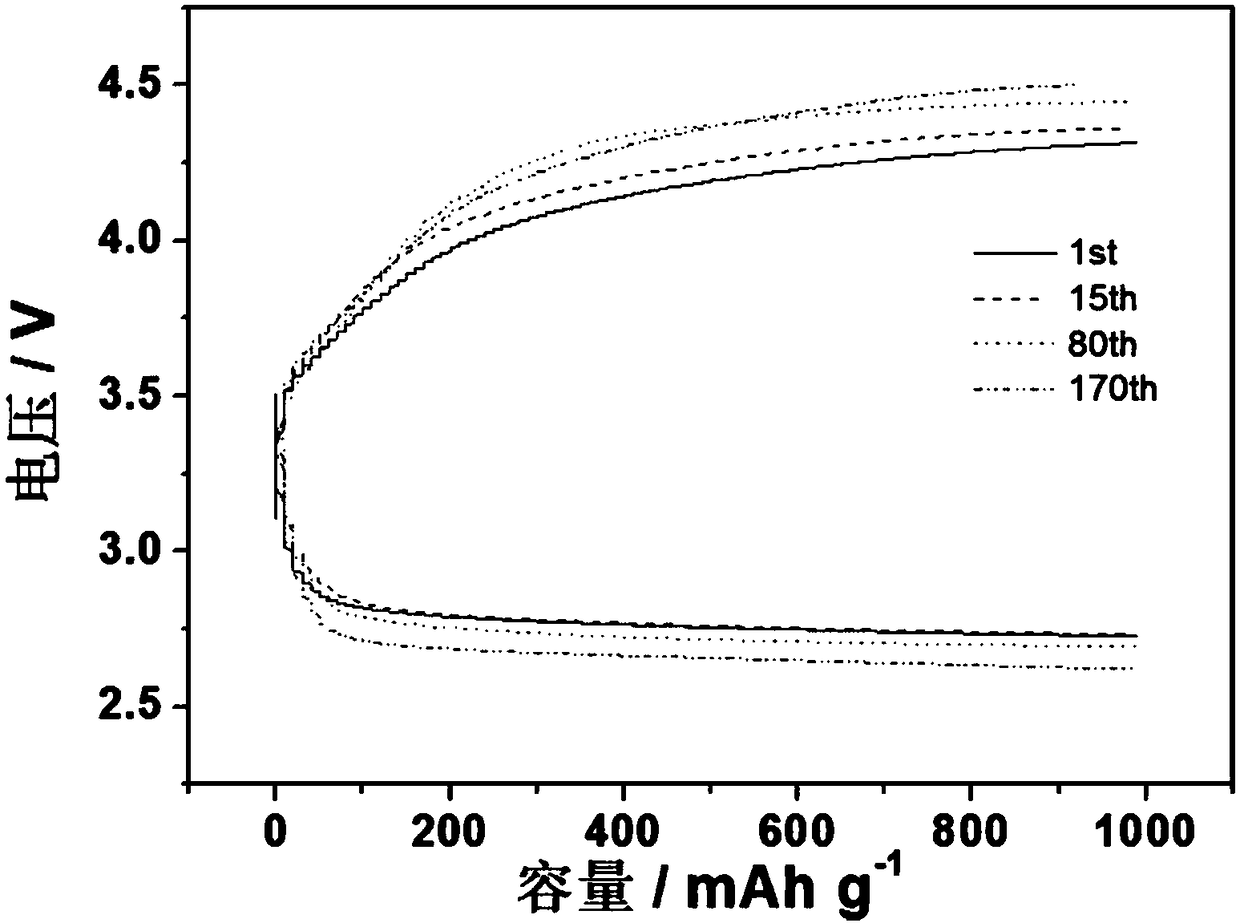

Embodiment 1

[0022] (1) Battery structure setting: a metal lithium sheet with a diameter of 16 mm is used as the anode, and 50 μL is dissolved with 1 mol / L LiClO 4 DMSO is the electrolyte solution, borosilicate glass fiber is the separator, and the cathode is a graphene-loaded 1cm 2 Carbon paper with a loading of 0.2 mg / cm 2 .

[0023] (2) Charging and discharging system setting: the charging and discharging range is 2 V to 4.5 V, the charging and discharging current density is 1000 mA / g, the charging and discharging capacity is 2000 mAh / g, and a button battery is assembled.

[0024] (3) The battery was left to stand in the glove box for 12 hours, and the charging and discharging range was set at 2 V to 4.5 V.

[0025] (4) The activated charge and discharge current density is 800 mA / g, and the activated capacity is 300 mAh / g.

[0026] (5) The number of activation cycles is 30.

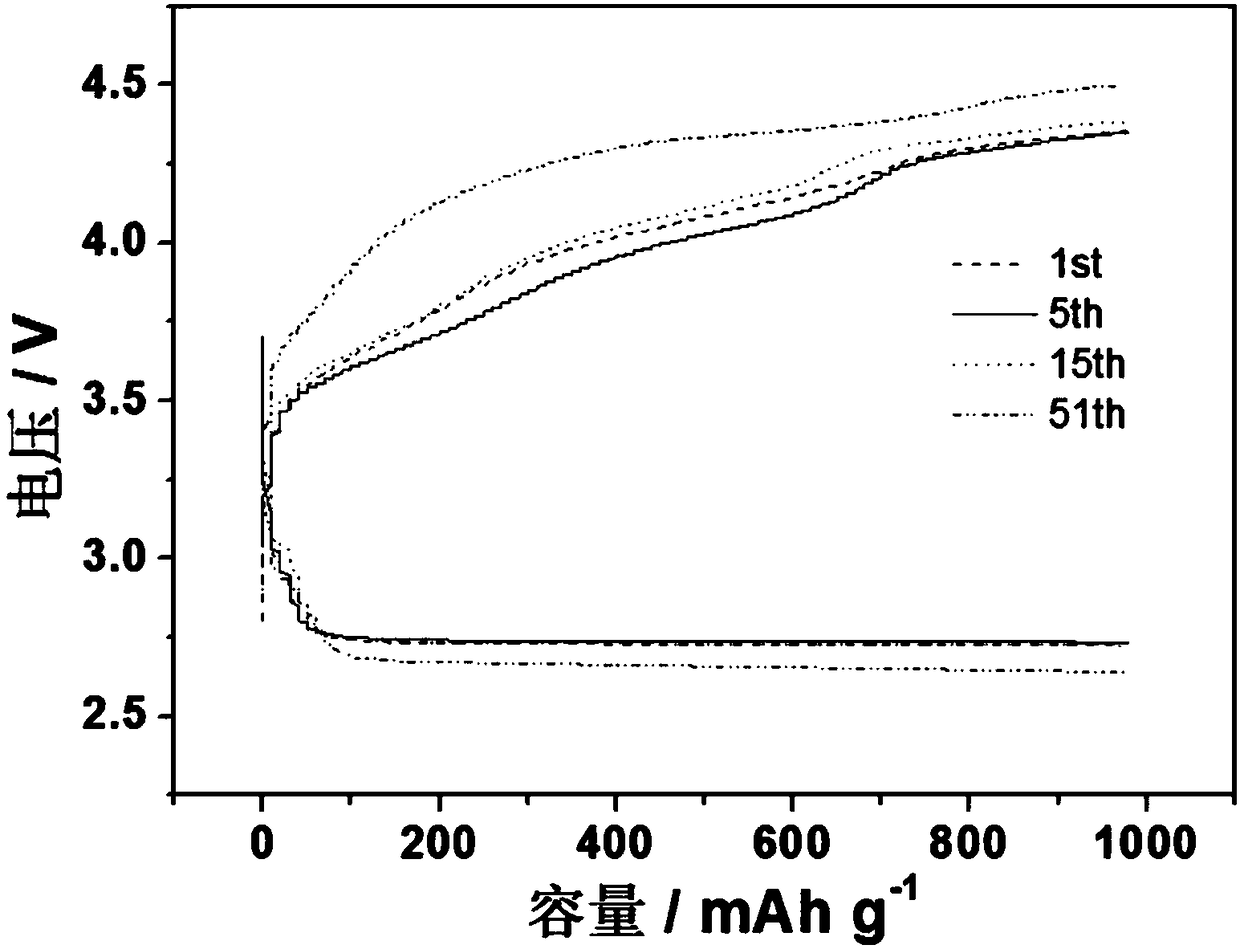

Embodiment 2

[0028] (1) Battery structure setting: a metal lithium sheet with a diameter of 14 mm is used as the anode, 70 μL of DME dissolved with 0.5 mol / L LiTFSI is used as the electrolyte solution, borosilicate glass fiber is used as the separator, and the cathode is a 1 cm carbon nanotube-supported 2 Carbon paper with a loading of 0.5mg / cm 2 , to assemble the simulated battery.

[0029] (2) Charge and discharge system setting: the charge and discharge range is 2 V to 4.5 V, the charge and discharge current density is 2000 mA / g, and the charge and discharge capacity is 3000 mAh / g.

[0030] (3) The battery was left to stand in the glove box for 24 hours, and the charging and discharging range was set at 2 V to 4.5 V.

[0031] (4) The activated charge and discharge current density is 500 mA / g, and the activated capacity is 800 mAh / g.

[0032] (5) The number of activation cycles is 20.

Embodiment 3

[0034] (1) Battery structure setting: a metal lithium sheet with a diameter of 18 mm is used as the anode, and 1 mol / L LiPF is dissolved in 80 μL 6 TEGDME is the electrolyte solvent, nylon 66 is the separator, and the cathode is a 1cm carbon black loaded 2 Carbon paper with a loading of 0.1 mg / cm 2 , Assemble the button battery.

[0035] (2) Charge and discharge system setting: the charge and discharge range is 2 V to 4.5 V, the charge and discharge current density is 3000 mA / g, and the charge and discharge capacity is 5000 mAh / g.

[0036] (3) The battery was left to stand in the glove box for 48 hours, and the charging and discharging range was set at 2 V to 4.5 V.

[0037] (4) The activated charge and discharge current density is 400 mA / g, and the activated capacity is 500 mAh / g.

[0038] (5) The number of activation cycles is 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com