Preparation method of high anthocyanin content mulberry wine

A technology for high anthocyanin and mulberry wine, which is applied in the field of wine making and achieves the effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

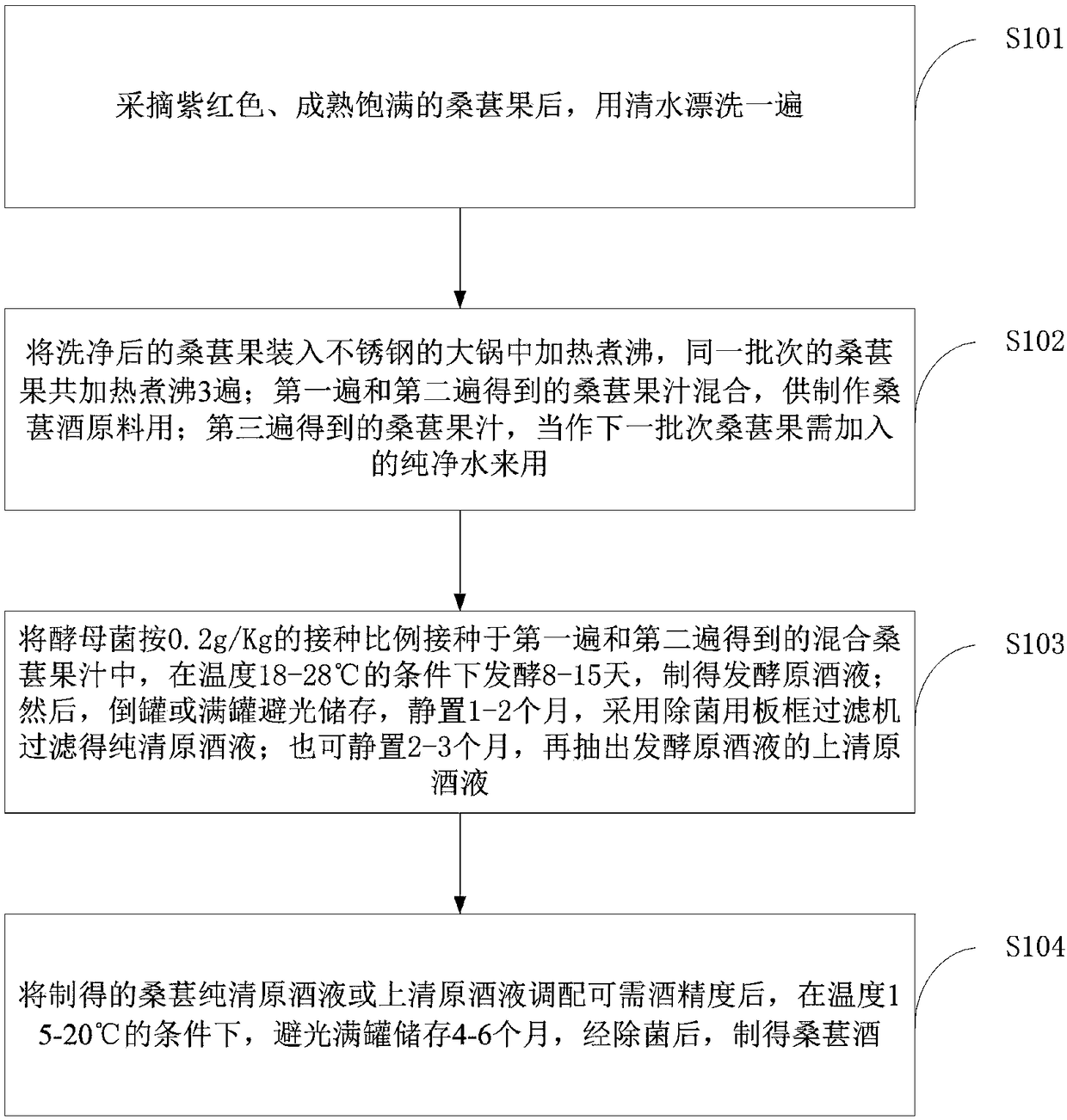

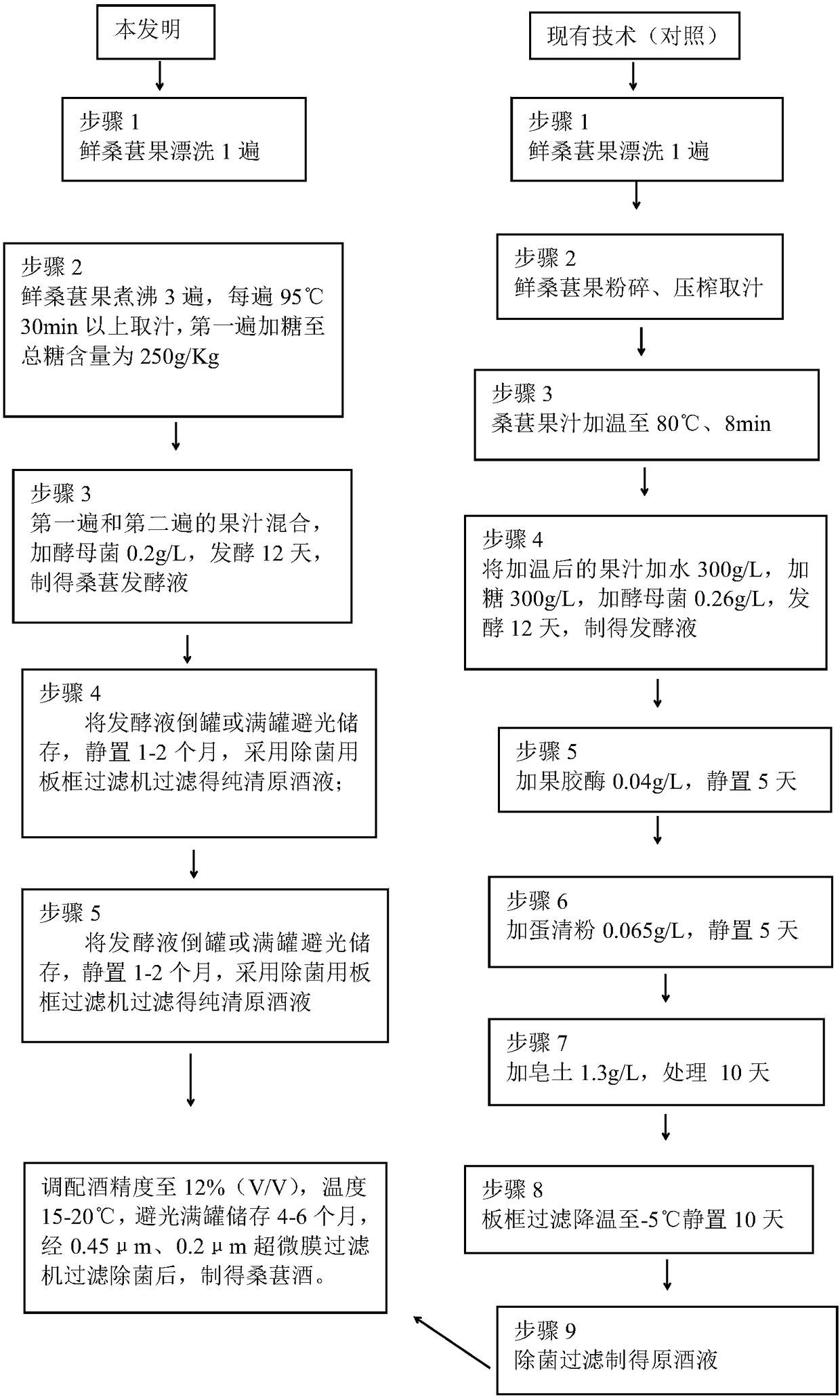

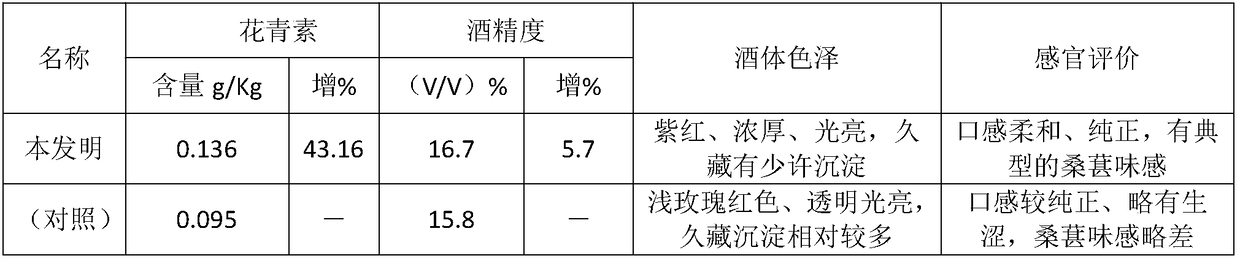

[0047] A large amount of pulp is pressed in the juice during pressing in the prior art. Although it is processed by adding a clarifier, some pulp and melanin precipitation will inevitably occur in the wine liquid, which will affect the sensory quality of the mulberry product wine. Adding substances such as pectinase or sulfur dioxide to varying degrees has a greater impact on the taste of mulberry wine. A method for preparing mulberry wine with high anthocyanin content is provided. The method includes the following steps:

[0048] A preparation method of mulberry wine with high anthocyanin content.

[0049] S101, after picking purple-red, ripe and plump mulberries, rinse them with clean water;

[0050] S102. Put the washed mulberry fruit into a stainless steel cauldron and heat to boil. The same batch of mulberry fruit is heated and boiled 3 times; the mulberry juice obtained in the first and second times is mixed for making mulberry wine. ; The mulberry juice obtained in the...

example 1

[0062] Explanation: The juice yield of fresh mulberry fruit is 70%. The total weight of mulberry juice obtained in the first and second passes is 30Kg. Theoretical conversion is: 21Kg of raw mulberry juice and 9Kg of purified water, which is equivalent to adding 30% of mulberry juice to 10 parts of mulberry juice. Pure water fermented.

[0063] Rinse the ripe and plump mulberry fruit with clean water, then put 30Kg of the washed mulberry fruit into a stainless steel cauldron, add 20Kg of pure water, 15% of the sugar content of the mulberry fruit, add 4.35Kg of sucrose, heat and boil, After boiling, continue to heat for 25 minutes on high heat, and 15 minutes on medium heat, at intervals between high and medium heat, and turn it with a spoon every 30 seconds to 1 minute. Simply dry the mulberry fruit in a colander full of mulberry fruit, then take out the mulberry juice in the pot, and then filter it with a 150-mesh filter to remove the mulberry fruit seeds floating on the juic...

example 2

[0071] Explanation: The juice yield of fresh mulberry fruit is 70%. The weight of mulberry juice obtained by the first pass is 21Kg. In theoretical conversion, the original mulberry juice is 21Kg. It is used to prepare mulberry wine, without adding purified water, and 100% of the original juice is fermented.

[0072] ⑴Rinse the ripe and plump mulberry fruit with clean water, then put 30Kg of the washed mulberry fruit into a stainless steel cauldron, add 20Kg of pure water, the sugar content of the mulberry fruit is 15%, add 2.1Kg of sucrose, and heat to boil , after boiling, get juice for the first time with example 1, get about 21Kg of mulberry fruit juice for the first time, for preparing mulberry wine.

[0073] ⑵The operation steps of the second and third times to get mulberry juice are the same as the first time, except that 25Kg of purified water is added to the third time, and no filtration is required. Batches of mulberries need to be added with purified water.

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com