Wafer level GaN device substrate transfer method

A substrate transfer, wafer-level technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Such as Figure 1~5 As shown, according to the wafer bonding method implemented in the present invention, the method includes the following steps:

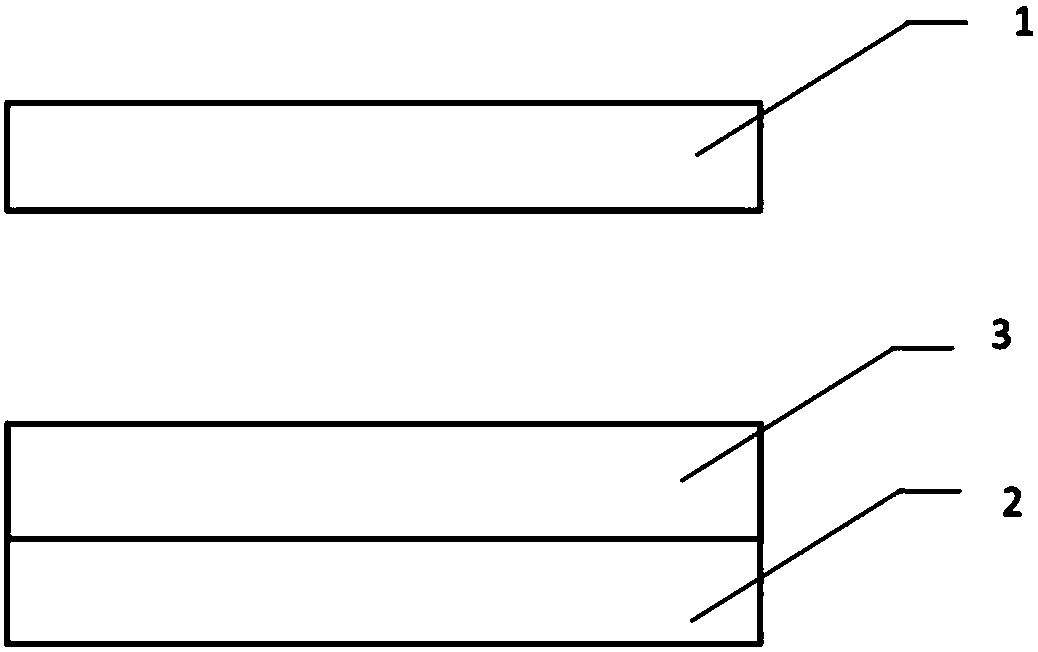

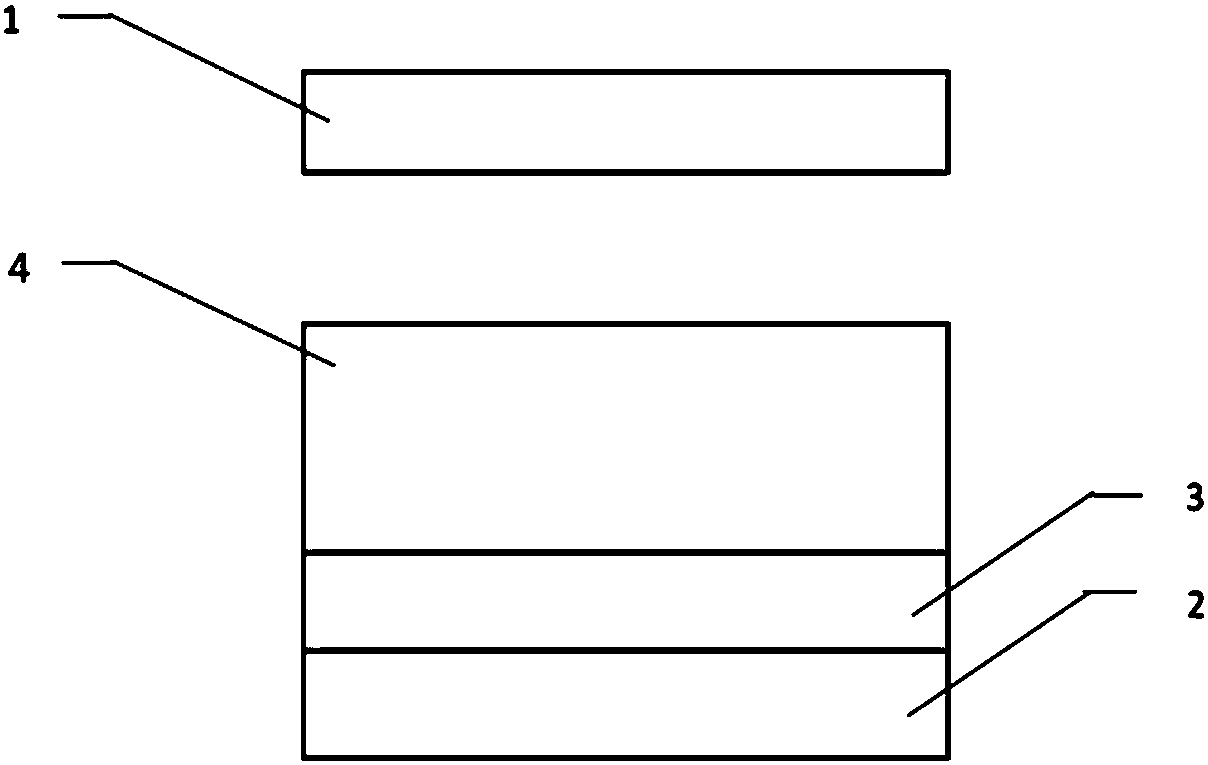

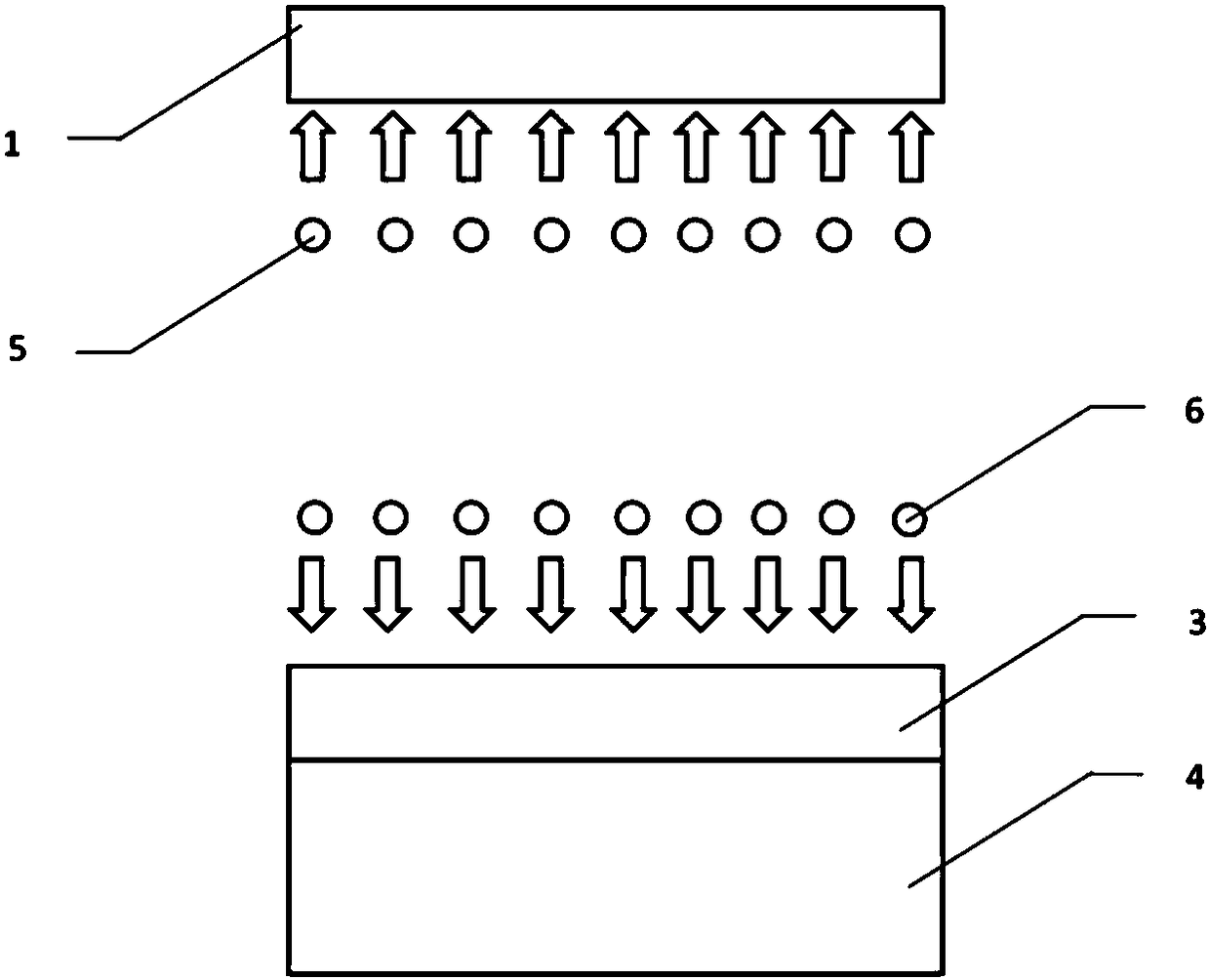

[0038] Step 1: After the front-side process of wafer-level GaN device 3 is completed, spin-coat photosensitive BCB4 on the surface of the wafer, set the rotation speed to 1000rpm, and take 1min; place the GaN device wafer on a hot plate and heat it to remove the solvent in the BCB glue , The heating temperature is kept at 100 ℃ ~ 200 ℃ to prevent the BCB glue from being removed after the transfer is completed due to high temperature BCB curing. figure 1 It is a schematic diagram of the cross-section of the wafer before bonding, figure 2 Schematic diagram of the cross-section of a spin-coated photosensitive BCB on the surface of a GaN device after the front-side process is completed.

[0039] Step 2: The sapphire substrate 2 is peeled off by a KrF excimer laser.

[0040] Step 3: Cleaning the Si wafer 1 and the GaN device...

Embodiment 2

[0048] Step 1: After the front-side process of wafer-level GaN device 3 is completed, spin-coat photosensitive BCB4 on the surface of the wafer, set the rotation speed to 1000rpm, and take 1min; place the GaN device wafer on a hot plate and heat it to remove the solvent in the BCB glue , The heating temperature is kept at 100°C to prevent the high-temperature BCB from curing and the BCB glue cannot be removed after the transfer is completed. figure 1 It is a schematic diagram of the cross-section of the wafer before bonding, figure 2 Schematic diagram of the cross-section of a spin-coated photosensitive BCB on the surface of a GaN device after the front-side process is completed.

[0049] Step 2: removing the SiC substrate or Si substrate on which the heteroepitaxially grown GaN is grown;

[0050] Step 3: Cleaning the Si wafer 1 and the GaN device wafer 3 after removing the substrate by standard RCA. Specifically, when the surface roughness of the wafer is large (usually gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com