Tungsten silicide nitride films and methods of formation

A technology of tungsten nitride layer and silicon nitride, which is applied in the direction of vacuum evaporation plating, coating, transistor, etc., can solve the problems of inability to provide gate stack resistivity, unsatisfactory adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present disclosure relates to tungsten silicide films and methods of depositing tungsten silicide films. In at least some embodiments, the inventive films and methods described herein beneficially reduce or eliminate spalling of the tungsten that is deposited to form a gate electrode stack of tungsten while maintaining a suitable gate stack resistivity, and Substantially neutral substrate stress is maintained.

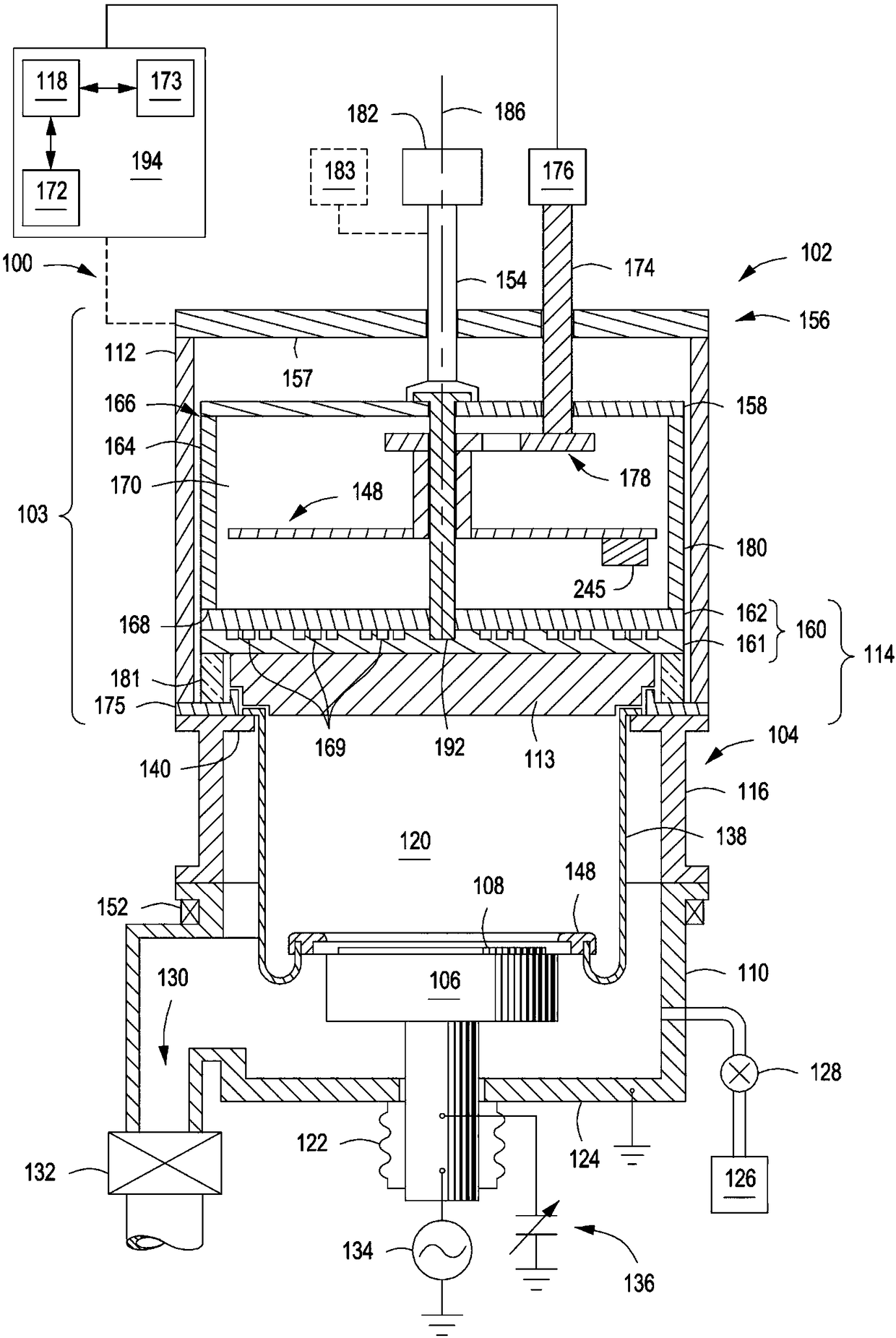

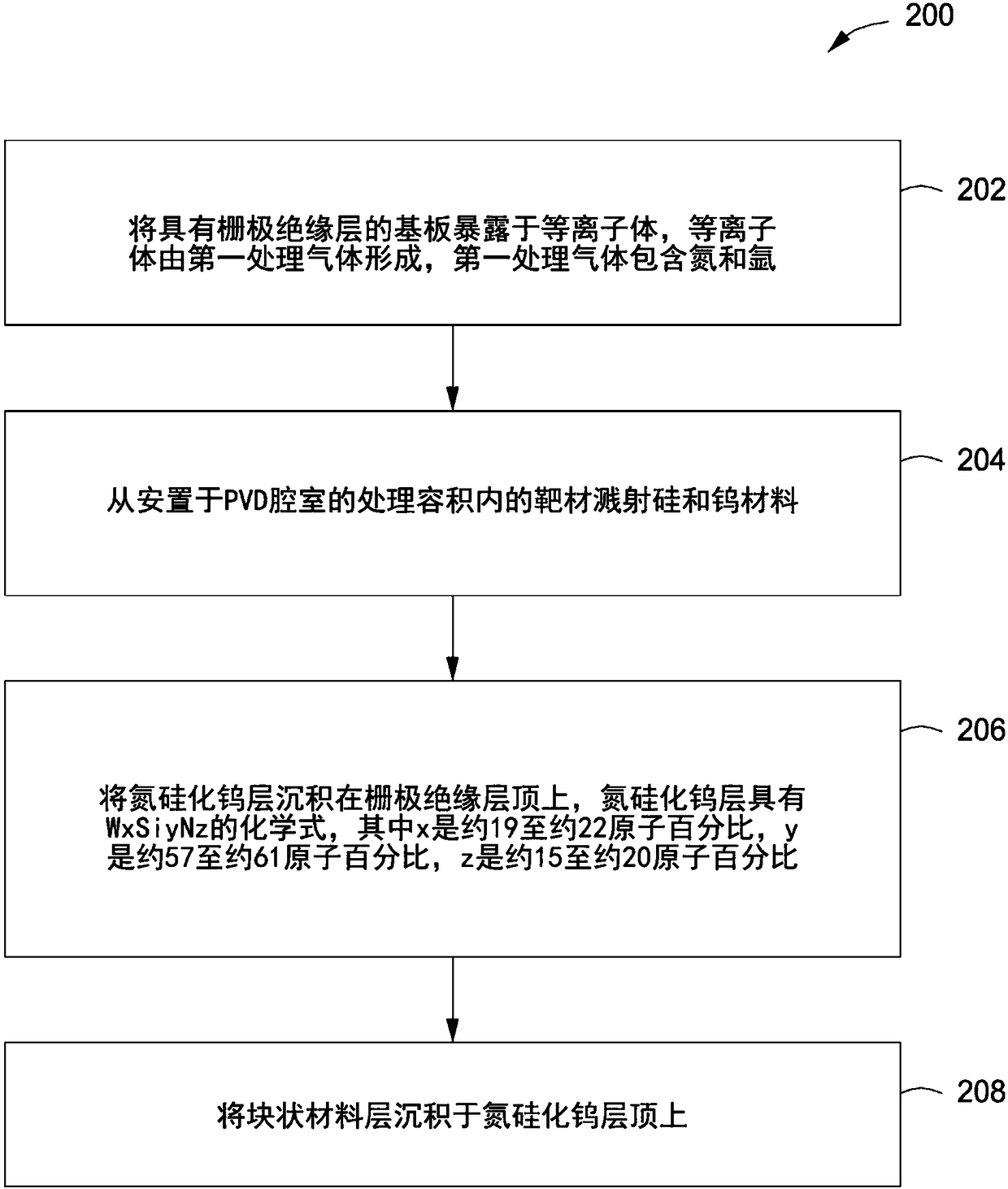

[0014] According to some embodiments of the present disclosure, figure 1 A simplified cross-sectional view of an illustrative physical vapor deposition (PVD) processing system 100 is depicted. figure 2 A flow chart depicting a method 200 of depositing a dielectric layer atop a substrate positioned such as figure 1 The type of physical vapor deposition processing system. hereinafter related to Figure 3A to Figure 3D The depicted stages of processing a substrate describe method 200 . An example of a PVD chamber suitable for performing the method 200 des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com