Preparation method and application of Fe-Cu binary oxide adsorbent for removing antimony

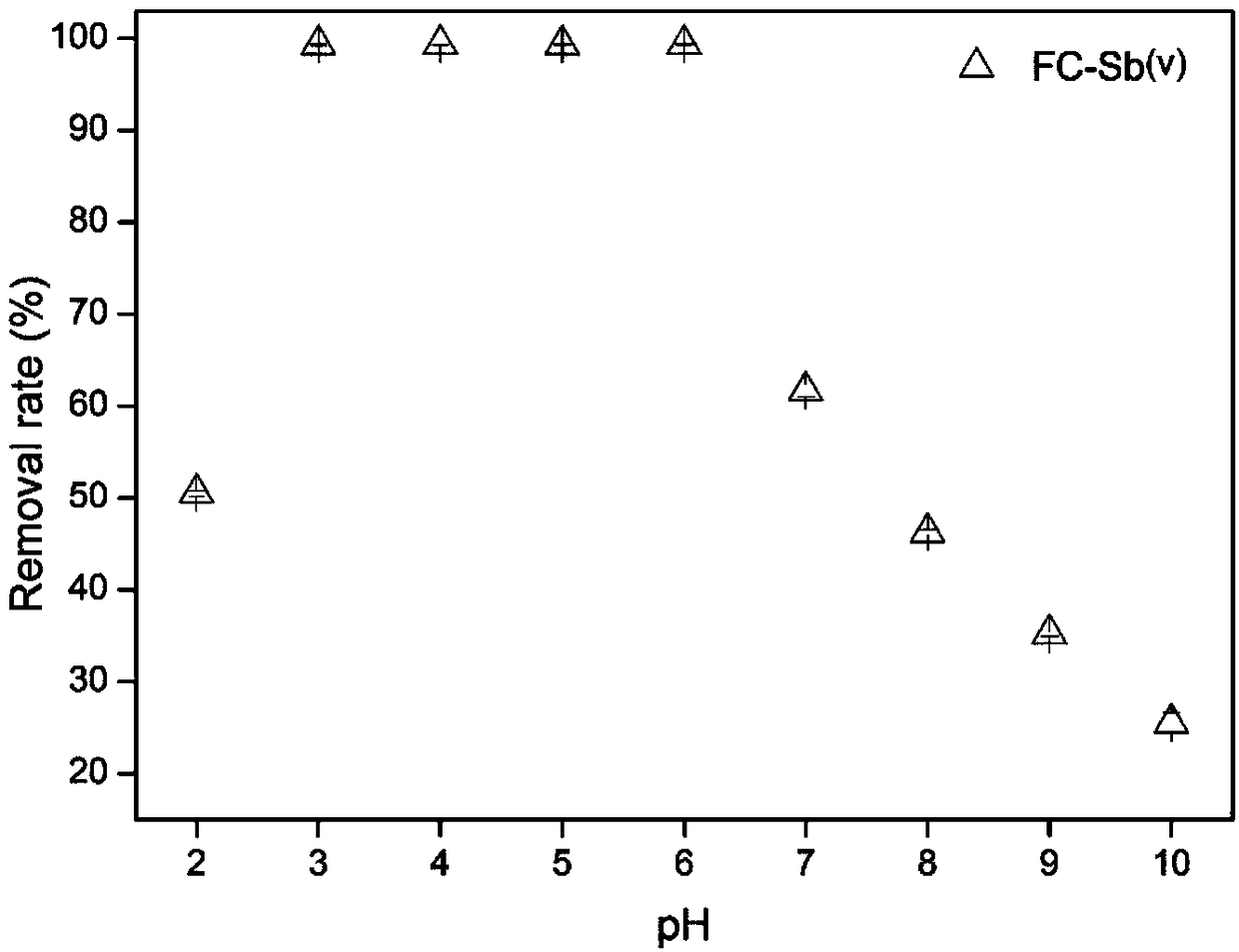

A binary oxide and adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the difficulty of removing antimony, low adsorption capacity and adsorption selectivity, weak adsorption reaction activity, etc. To achieve the effect of improving the synergistic adsorption and removal capacity, the preparation method is simple, and the superior adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

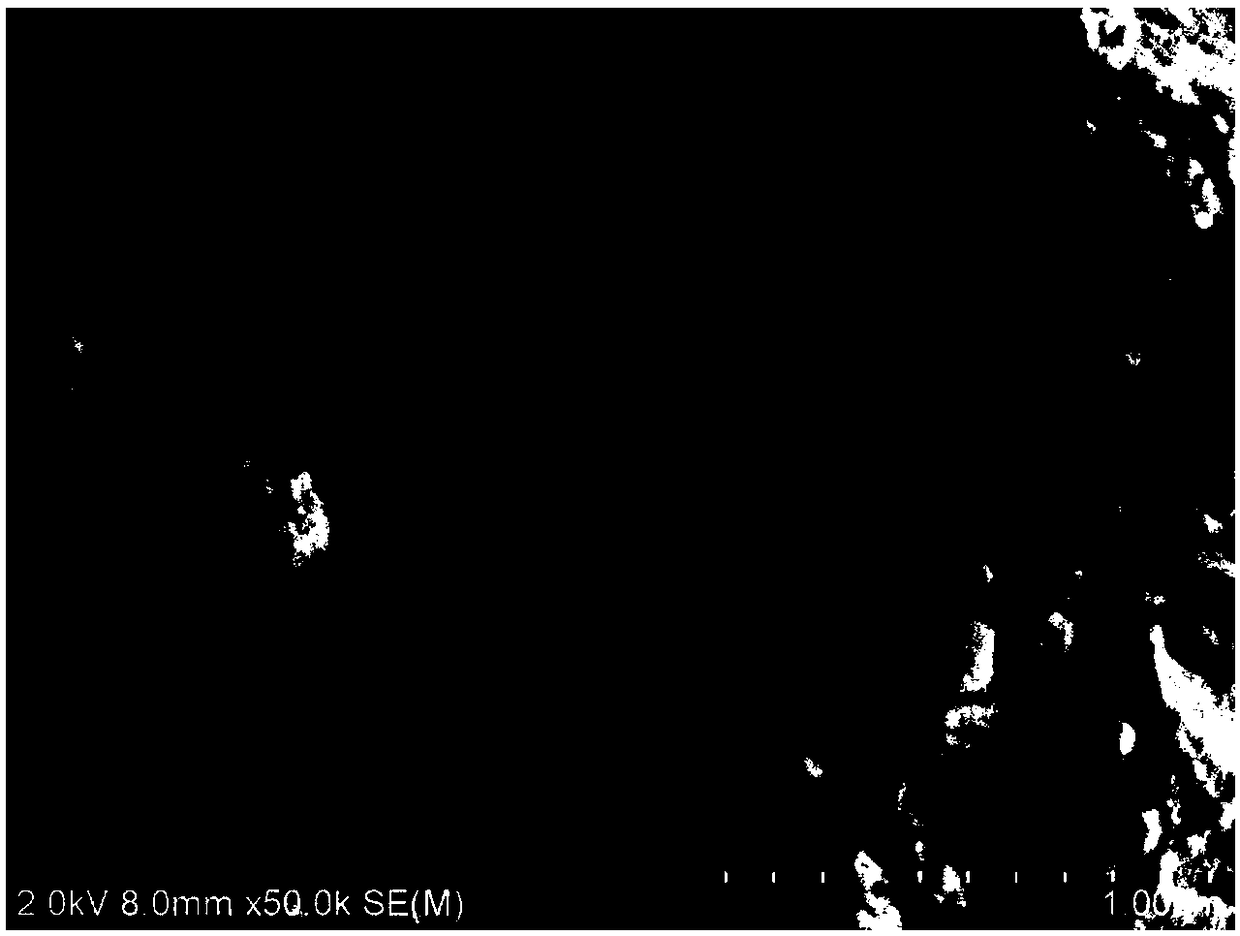

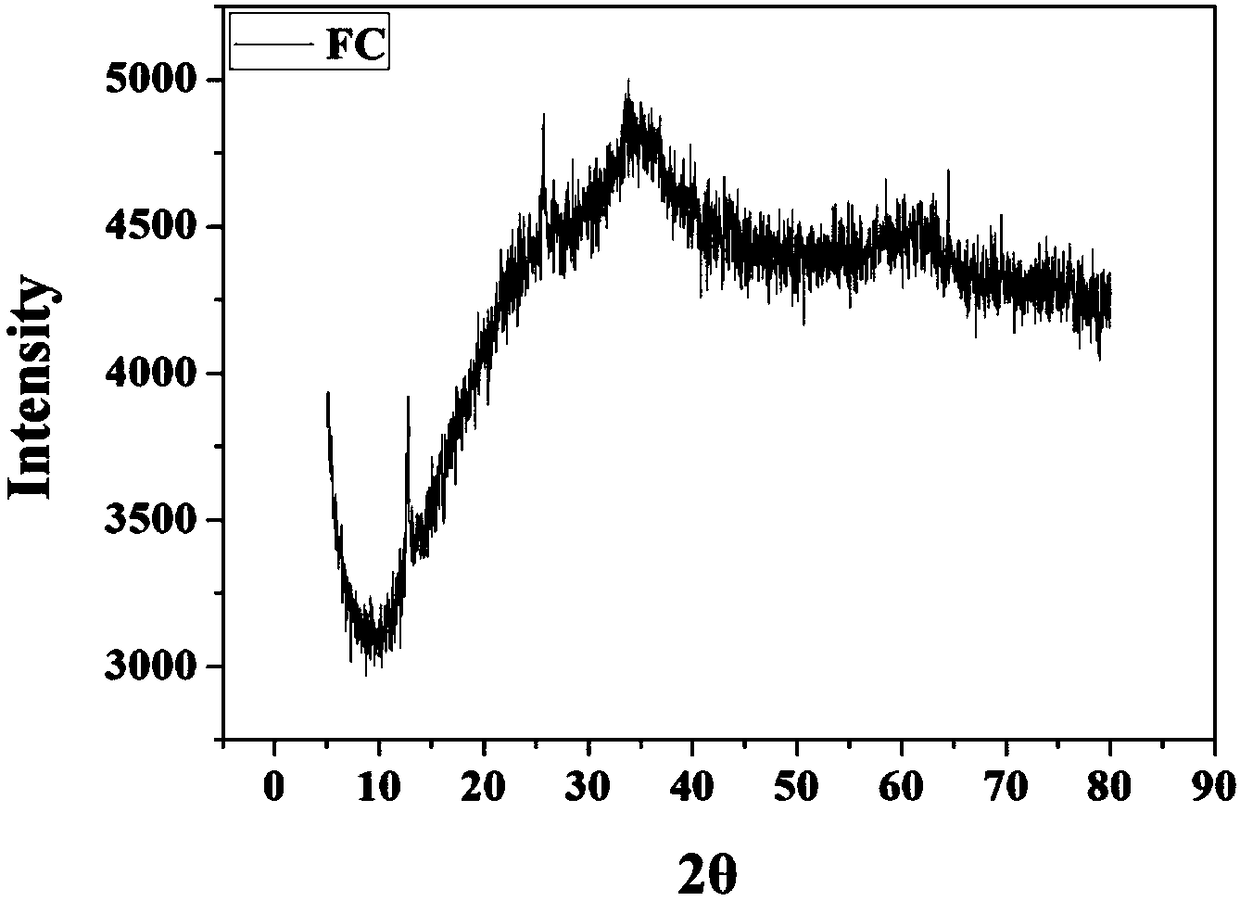

[0029] Example 1: Preparation method of Fe-Cu binary oxide adsorbent for removing antimony of the present invention

[0030] Add 20mmol iron nitrate (Fe(NO 3 ) 3 ) And 10mmol copper nitrate (Cu(NO 3 ) 2 ) Dissolve in 1L of oxygen-free deionized water, stir the two solutions vigorously with a magnetic stirrer at 1000 rpm, and add 5M NaOH aqueous solution dropwise to keep the pH at 7.00±0.02, and ultrasonicate the resulting mixture Disperse for 30 minutes, continue stirring the resulting suspension at 200 rpm for 0.8 hours, and aging for 5 hours at room temperature, so that an activated layer with strong adsorption capacity is formed on the surface of the adsorbent material, precipitates and solid-liquid separation, and then the brown precipitate is used to remove Wash with ionized water 5 times. The ratio of the volume of the washing water to the volume of the reaction system is 2:1 until the pH of the washed water is 7.0. The suspended solids are centrifuged to discard the superna...

Embodiment 2

[0031] Example 2: Preparation method of Fe-Cu binary oxide adsorbent for removing antimony of the present invention

[0032] Dissolve 4mmol of iron sulfate and 1mmol of copper sulfate in 1L of oxygen-free deionized water respectively, stir the two solutions vigorously with a magnetic stirrer at 1000rpm, and add 5M NaOH aqueous solution dropwise to keep the pH at 9.0. The resulting mixture was ultrasonically dispersed for 50 minutes, and the resulting suspension was stirred at 200 rpm for 1 hour, and aged for 7 hours at room temperature, so that an active layer with strong adsorption capacity was formed on the surface of the adsorbent material, which precipitated and separated solid and liquid. The brown precipitate was washed 5 times with deionized water, and the ratio of the volume of the washing water to the volume of the reaction system was 2:1 until the pH of the washed water was 7.0. The suspended solids were centrifuged to discard the supernatant and dried at 150°C (Vacuum ...

Embodiment 3

[0033] Example 3: Preparation method of Fe-Cu binary oxide adsorbent for removing antimony of the present invention

[0034] Dissolve 2mmol ferric chloride and 10mmol copper chloride in 1L of oxygen-free deionized water respectively, stir the two solutions vigorously with a magnetic stirrer at 1000rpm, and add 5M NaOH aqueous solution dropwise to keep the pH at 6.0 , Disperse the resulting mixture ultrasonically for 10 minutes, continue to stir the resulting suspension at 200 rpm for 0.5 hours, and age at room temperature for 3 hours, so that an active layer with strong adsorption capacity is formed on the surface of the adsorbent material, which precipitates and separates solid-liquid , And then wash the brown precipitate with deionized water 5 times. The ratio of the volume of the washing water to the volume of the reaction system is 2:1 until the pH of the washed water is 7.0. The suspended solids are centrifuged and the supernatant is discarded at 110°C. After drying (vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com