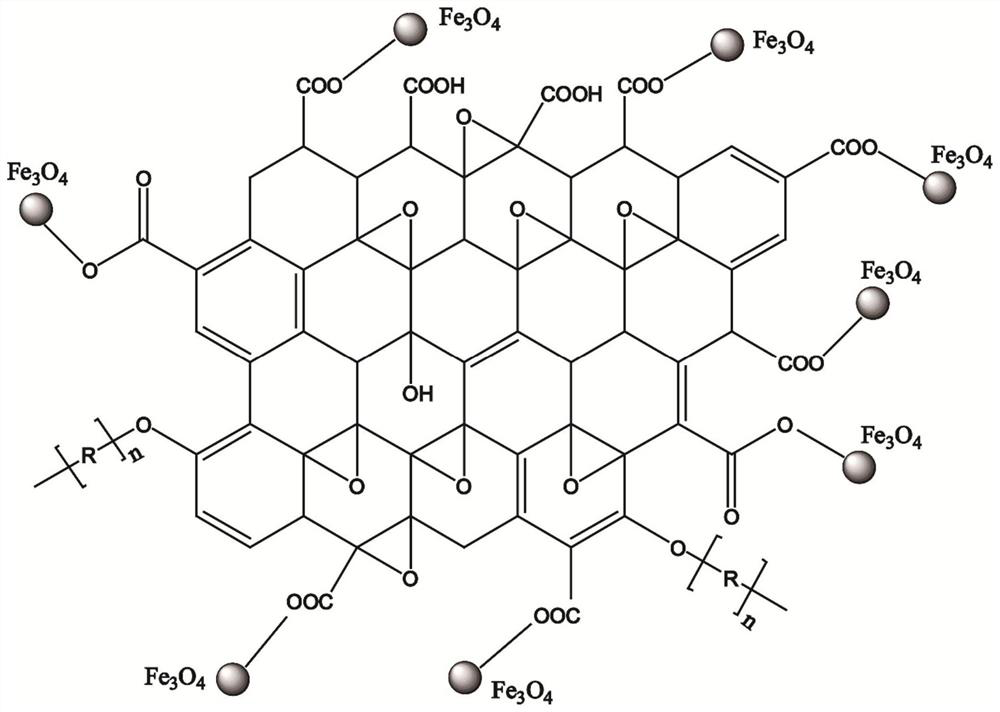

A modified magnetic graphene oxide adsorbent with plate-brush structure and its preparation method and application

A technology of oxidized rock and adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of weak selective adsorption, non-biodegradable, poor adsorption effect, etc. , to achieve the effect of increasing the adsorption capacity, good capture and removal effect, and poor recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

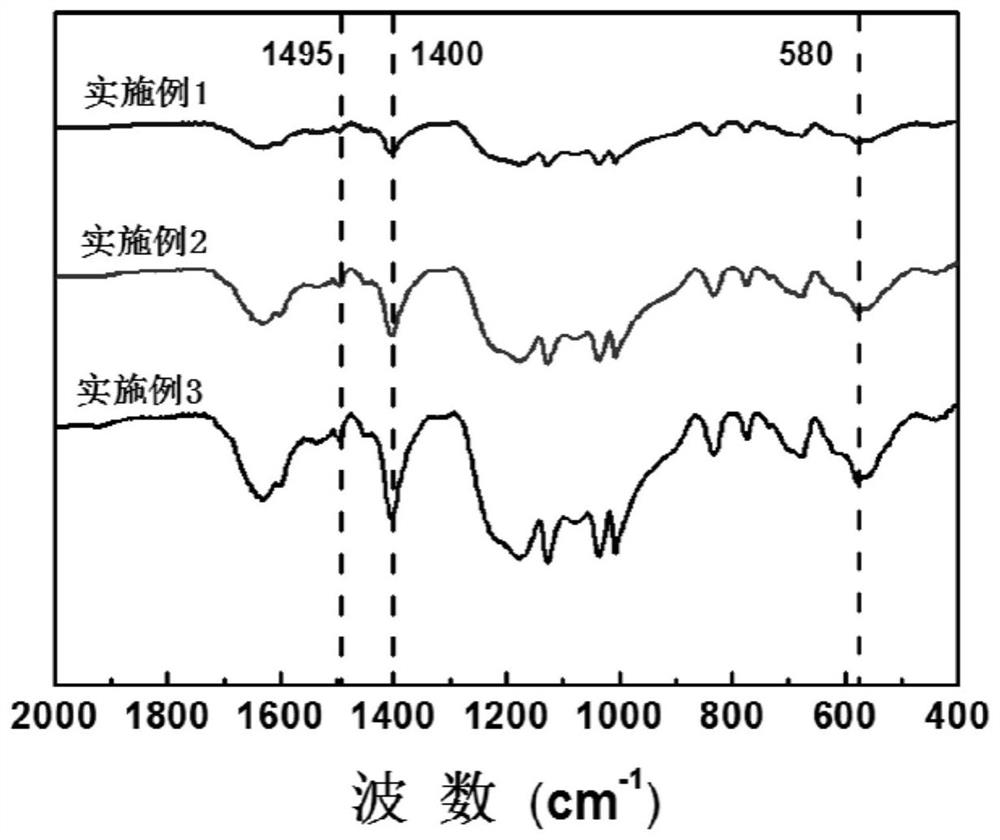

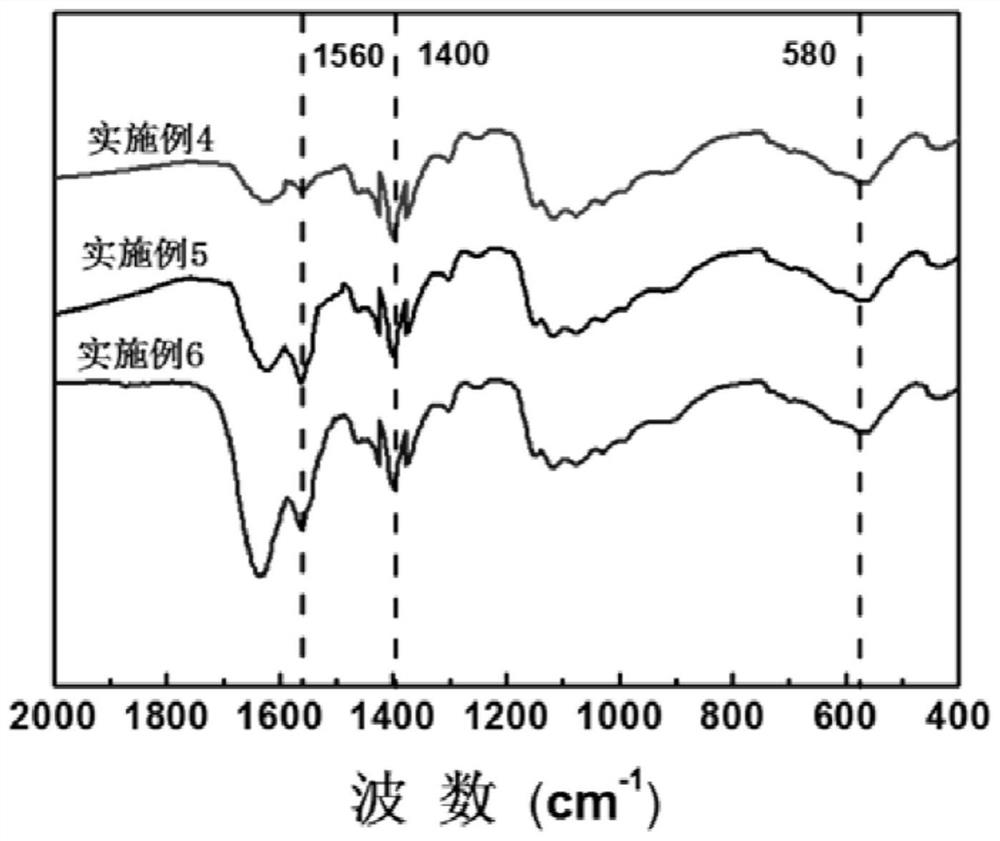

Embodiment 1

[0043] The preparation method is as follows:

[0044] Measure 230 mL of concentrated sulfuric acid with a mass fraction of 98%, and cool it to 0°C in an ice-water bath. Take 7g of graphite and 5g of sodium nitrate and slowly add them to concentrated sulfuric acid. Then carefully add a certain amount of potassium permanganate (the mass ratio of graphite to potassium permanganate is 1:3) at a stirring speed of 150rpm, and ensure that the system temperature does not exceed 5°C during this period. After the addition is complete, remove the ice-water bath, then carefully raise the temperature of the reaction system to about 35°C, and react at this temperature for 120 minutes. After the reaction was completed, 400 mL of water was carefully added dropwise to the system at a stirring speed of 300 rpm at a rate of 2 drops per second, and then the temperature of the system was raised to 95°C. Add 50 mL of 30% hydrogen peroxide. The crude product was filtered out, washed with 5% dilut...

Embodiment 2

[0051] The preparation method is as follows:

[0052] Measure 230 mL of concentrated sulfuric acid with a mass fraction of 98%, and cool it to 0°C in an ice-water bath. Take 7g of graphite and 5g of sodium nitrate and slowly add them to concentrated sulfuric acid. Then carefully add a certain amount of potassium permanganate (the mass ratio of graphite to potassium permanganate is 1:4) at a stirring speed of 150rpm, and ensure that the system temperature does not exceed 5°C during this period. After the addition is complete, remove the ice-water bath, then carefully raise the temperature of the reaction system to about 35°C, and react at this temperature for 120 minutes. After the reaction was completed, 400 mL of water was carefully added dropwise to the system at a stirring speed of 300 rpm at a rate of 2 drops per second, and then the temperature of the system was raised to 95°C. Add 50 mL of 30% hydrogen peroxide. The crude product was filtered out, washed with 5% dilut...

Embodiment 3

[0059] The preparation method is as follows:

[0060] Measure 230 mL of concentrated sulfuric acid with a mass fraction of 98%, and cool it to 0°C in an ice-water bath. Take 7g of graphite and 5g of sodium nitrate and slowly add them to concentrated sulfuric acid. Then carefully add a certain amount of potassium permanganate (the mass ratio of graphite to potassium permanganate is 1:15) at a stirring speed of 150rpm, and ensure that the system temperature does not exceed 5°C during this period. After the addition is complete, remove the ice-water bath, then carefully raise the temperature of the reaction system to about 35°C, and react at this temperature for 120 minutes. After the reaction was completed, 400 mL of water was carefully added dropwise to the system at a stirring speed of 300 rpm at a rate of 2 drops per second, and then the temperature of the system was raised to 95°C. Add 50 mL of 30% hydrogen peroxide. The crude product was filtered out, washed with 5% dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com