Method for preparing high-density ZrB2-ZrSi2-Cf ultra-high temperature ceramic composite material at low temperature

A technology of zrb2-zrsi2-cf, ultra-high temperature ceramics, applied in the field of material science, can solve problems such as difficult sintering and densification, and achieve the effects of promoting densification, increasing sintering driving force, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

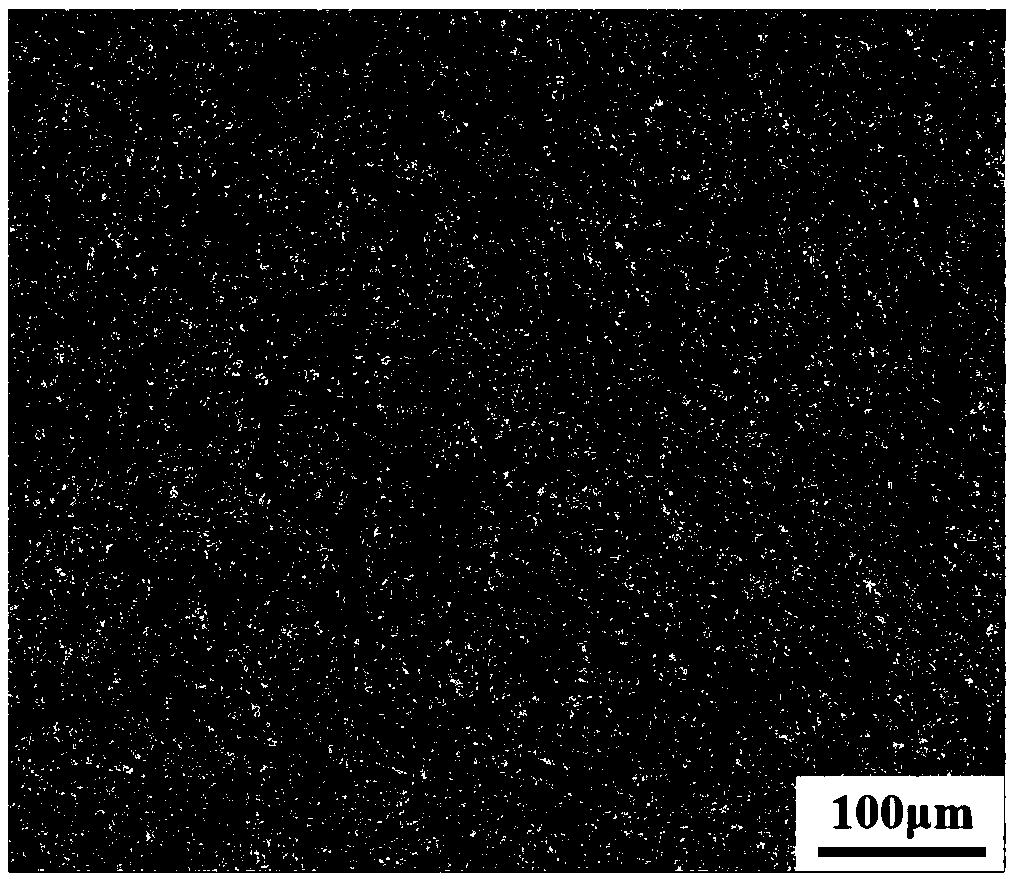

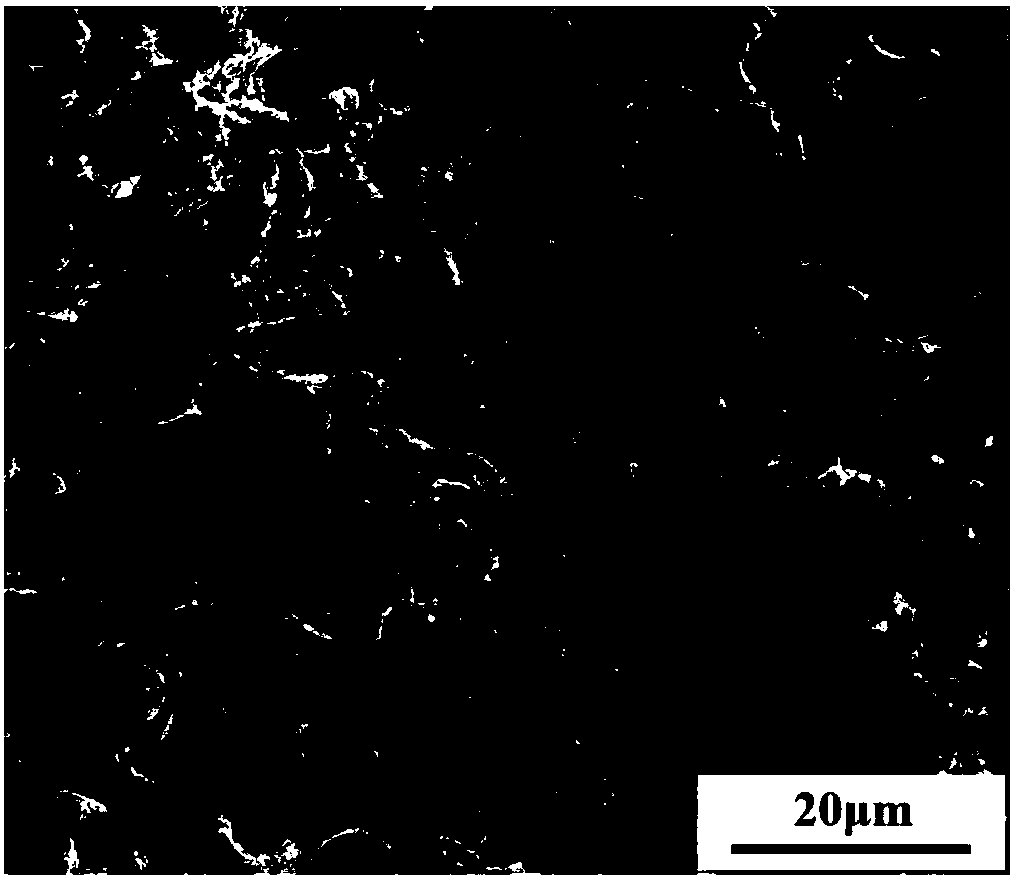

Image

Examples

Embodiment 1

[0022] A Low-Temperature Preparation of Highly Dense ZrB 2 -ZrSi 2 -C f The method for ultra-high temperature ceramic composite materials, the specific steps are as follows:

[0023] Step 1. Ingredients: Cut continuous carbon fiber into chopped carbon fiber with a length of 1-3 mm, and weigh ZrB in proportion 2 , ZrSi 2 powder and chopped carbon fiber, and added to absolute ethanol, ultrasonic treatment for 30min. Among them, ZrB 2 The average particle size of the powder is 200nm, and the volume fraction is 60%,; ZrSi 2 The average particle size of the powder is 100nm, and the volume fraction is 10%; the volume fraction of the chopped carbon fiber is 30%.

[0024] Step 2, ball milling: put the slurry obtained in step 1 into a ball mill tank for mechanical ball milling, the ball milling medium is absolute ethanol, the balls are made of tungsten carbide, the ball milling time is 15 hours, and the ball milling speed is 250r / min.

[0025] Step 3. Drying: Pour the ball-mille...

Embodiment 2

[0029] A Low-Temperature Preparation of Highly Dense ZrB 2 -ZrSi 2 -C f The method for ultra-high temperature ceramic composite materials, the specific steps are as follows:

[0030] Step 1. Ingredients: Cut continuous carbon fiber into chopped carbon fiber with a length of 1-3 mm, and weigh ZrB in proportion 2 , ZrSi 2 powder and chopped carbon fiber, and added to absolute ethanol, ultrasonic treatment for 20min. Among them, ZrB 2 The average particle size of the powder is 150nm, and the volume fraction is 60%,; ZrSi 2 The average particle size of the powder is 200nm, and the volume fraction is 20%; the volume fraction of the chopped carbon fiber is 20%.

[0031] Step 2, ball milling: put the slurry obtained in step 1 into a ball mill tank for mechanical ball milling, the ball milling medium is absolute ethanol, the balls are made of tungsten carbide, the ball milling time is 12 hours, and the ball milling speed is 220r / min.

[0032] Step 3. Drying: Pour the ball-mille...

Embodiment 3

[0036] A Low-Temperature Preparation of Highly Dense ZrB 2 -ZrSi 2 -C f The method for ultra-high temperature ceramic composite materials, the specific steps are as follows:

[0037]Step 1. Ingredients: Cut continuous carbon fiber into chopped carbon fiber with a length of 1-3 mm, and weigh ZrB in proportion 2 , ZrSi 2 Powder and chopped carbon fiber, and added to absolute ethanol, ultrasonic treatment for 35min. Among them, ZrB 2 The average particle size of the powder is 100nm, and the volume fraction is 60%,; ZrSi 2 The average particle size of the powder is 200nm, and the volume fraction is 15%; the volume fraction of the chopped carbon fiber is 25%.

[0038] Step 2, ball milling: put the slurry obtained in step 1 into a ball mill tank for mechanical ball milling, the ball milling medium is absolute ethanol, the balls are made of tungsten carbide, the ball milling time is 15 hours, and the ball milling speed is 240r / min.

[0039] Step 3. Drying: Pour the ball-milled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com