Acid and alkali resistant UV visbreaking composition, UV visbreaking film and preparation method thereof

A technology of acid and alkali resistance and composition, applied in the field of protective film, can solve the problem of insufficient tolerance in acid and alkali environment, and achieve the effect of high degree of crosslinking and curing, excellent adhesion, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

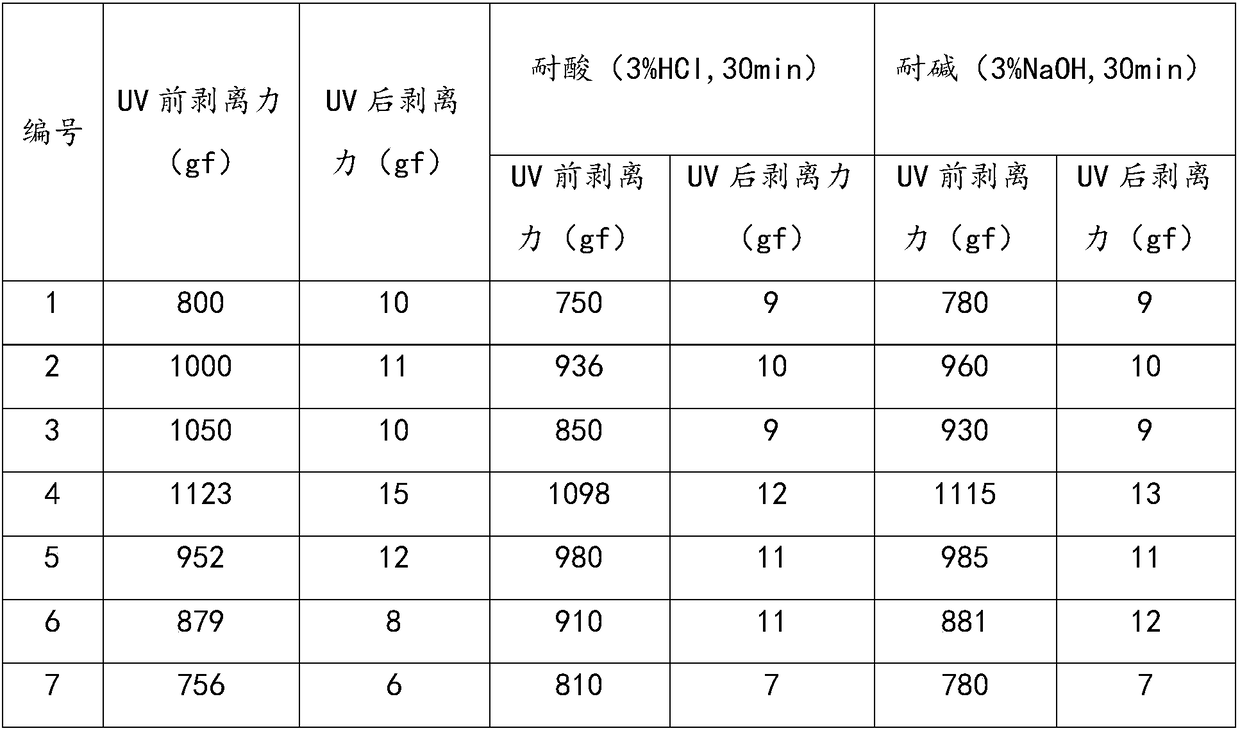

Examples

Embodiment 1

[0061] The acid and alkali resistant UV visbreaking composition described in the present embodiment has the following composition of raw materials:

[0062] 18g polyacrylate pressure-sensitive adhesive (manufacturer: Changxing Chemical Industry, model: ETERAC-77301), 3g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-8620W), 0.5g Photoinitiator (manufacturer: BASF, model: TPO), 0.7g isocyanate curing agent (manufacturer: BAYER, model: N3390), 30g of ethyl acetate.

[0063] Wherein, the UX-8620W is an aliphatic urethane acrylate oligomer.

Embodiment 2

[0065] The acid and alkali resistant UV visbreaking composition described in the present embodiment has the following composition of raw materials:

[0066] 20g polyacrylate pressure-sensitive adhesive (manufacturer: Changxing Chemical Industry, model: ETERAC-77303), 6g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-8620W), 0.5g Photoinitiator (manufacturer: Desheng Chemical, model: 1173), 1g curing agent (manufacturer: Shengping Chemical, model: npu100), 22g of butanone.

Embodiment 3

[0068] The acid and alkali resistant UV visbreaking composition described in the present embodiment has the following composition of raw materials:

[0069] 30g polyacrylate pressure-sensitive adhesive (manufacturer: Changxing Chemical Industry, model: ETERAC-77303), 6g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-8620W), 0.5g Photoinitiator (manufacturer: Desheng Chemical, model: 1173), 1 g curing agent (manufacturer: BAYER, model: N75), 22 g of butanone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com