Catalyzing system for preparing acetaldehyde by acetylene liquid-phase hydratation and application thereof

A catalytic system, acetylene liquid technology, applied in the chemical field, can solve environmental and human hazards and other problems, achieve the effects of reducing harmful effects, avoiding harm, and solving the dependence on mercury catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

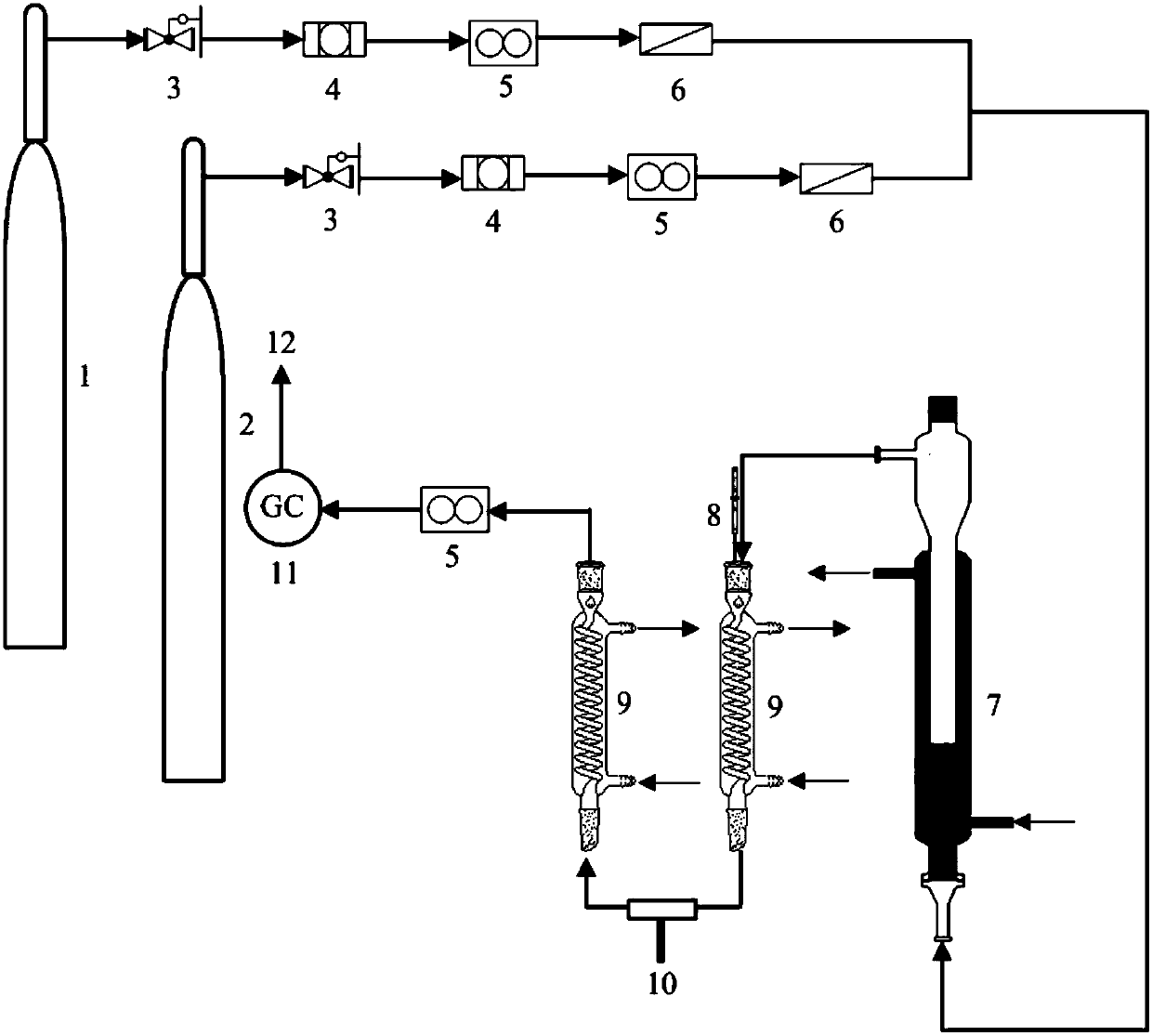

[0038] to combine figure 1 , the specific operation steps are as follows:

[0039] (1) After passing an inert gas into the reactor for 30 minutes and the temperature of the water bath reaches 60°C, add 1L of pure water solvent into the reactor, and after the temperature of the solvent is stabilized, add 5mol of ammonium chloride into the pure water solvent and make it Fully dissolved to obtain mixed solution 1;

[0040] (2) add 5mol cuprous chloride in mixed solution 1, treat that cuprous chloride dissolves completely, get mixed solution 2;

[0041] (3) After adding 30ml of 10mol / L hydrochloric acid solution and 1mol thiomalic acid to the mixed solution 2, continue nitrogen flow for 20min, remove the air in the reaction system, and mix uniformly to obtain a catalytic system;

[0042] (4) Then at 60°C, the air velocity is 100h -1 The acetylene gas, so that it undergoes hydration reaction in the reactor, the generated acetaldehyde and by-products enter the serpentine condense...

Embodiment 2

[0045] to combine figure 1 , the specific operation steps are as follows:

[0046] (1) After passing inert gas into the reactor for 30 minutes and the temperature of the water bath reaches 50°C, add 1L of mixed solvent into the reactor (the mixed solvent is N,N-dimethylformamide and water according to the volume ratio of 1:2.3 mixed), after the temperature of the solvent was stabilized, 2 mol of potassium chloride was added to the mixed solvent and fully dissolved to obtain the mixed solution 1;

[0047] (2) add 10mol cuprous chloride in mixed solution 1, treat that cuprous chloride dissolves completely, get mixed solution 2;

[0048] (3) After adding 0.5mol thiosalicylic acid and 0.5mol thioethanol to the mixed solution 2, continue nitrogen flow for 20min, remove the air in the reaction system, and mix uniformly to obtain a catalytic system;

[0049] (4) Then at 50°C, the air velocity is 100h -1 The acetylene gas, so that it undergoes hydration reaction in the reactor, the...

Embodiment 3

[0052] combine figure 1 , the specific operation steps are as follows:

[0053] (1) After passing an inert gas into the reactor for 30 minutes and the temperature of the water bath reaches 95°C, add 1 L of mixed solvent into the reactor (the mixed solvent is made by mixing ionic liquid and water at a volume ratio of 1:1, and the ionic liquid is 1-butylsulfonic acid-3 methylimidazole trifluoromethanesulfonate), after the solvent temperature is stable, 3mol ammonium chloride and 2mol sodium chloride are added in the mixed solvent, and make it fully dissolve, get mixed solution 1 ;

[0054] (2) add 2mol cuprous chloride in mixed solution 1, treat that cuprous chloride dissolves completely, get mixed solution 2;

[0055] (3) After adding 25ml of 10mol / L nitric acid solution, 15ml of 10mol / L acetic acid solution and 0.1mol thioglycolic acid in the mixed solution 2, continue to flow nitrogen for 20min, remove the air in the reaction system, and mix uniformly to obtain catalytic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com