Preparation process of calcium carbonate

A preparation process and technology of calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of low purity, low yield and low quality of calcium carbonate, and achieve high product purity, high yield and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

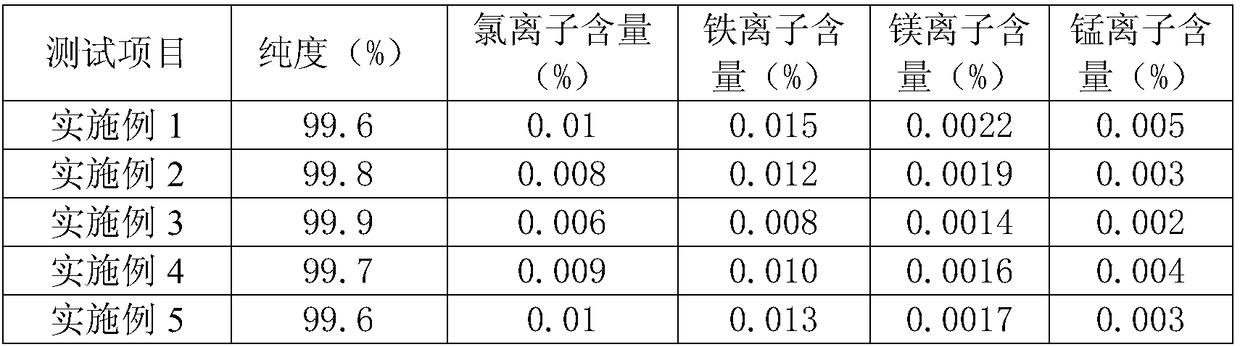

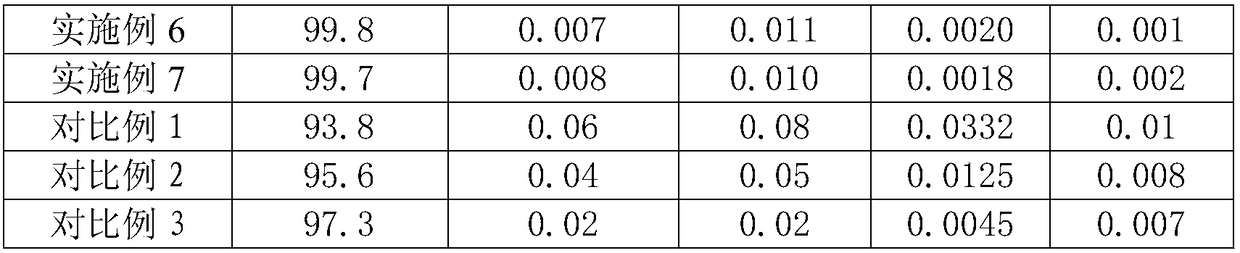

Examples

Embodiment 1

[0028] The preparation technology of the calcium carbonate of the present embodiment, comprises the following steps:

[0029] (1) adding calcium nitrate to deionized water, dissolving and preparing a calcium nitrate solution with a mass fraction of 40%;

[0030] (2) Add ammonia water to the calcium nitrate solution at a temperature of 60° C., and add calcium hydroxide under strong alkaline pH conditions, stir evenly, let stand for 2 hours, and filter to obtain a refined solution;

[0031] (3) Ultrasonic atomize the refined solution into a refined atomized product, and pass the refined atomized product into the carbonization tower, then add ammonium bicarbonate to carry out carbonization reaction, control the carbonization temperature to 70 ° C, and the reaction time is 4 hours to obtain the intermediate product calcium carbonate materials;

[0032] (4) Add deionized calcium carbonate material to the intermediate product and heat it to 75°C, then add it into a stainless steel ...

Embodiment 2

[0042] The preparation technology of the calcium carbonate of the present embodiment, comprises the following steps:

[0043] (1) adding calcium nitrate to deionized water, dissolving and preparing a calcium nitrate solution with a mass fraction of 60%;

[0044] (2) Add ammonia water to the calcium nitrate solution at a temperature of 80° C., and ensure that the pH is strongly alkaline, add calcium hydroxide, stir evenly, let stand for 4 hours, and filter to obtain a refined solution;

[0045] (3) Ultrasonic atomize the refined solution into a refined atomized product, and pass the refined atomized product into the carbonization tower, then add ammonium bicarbonate to carry out carbonization reaction, control the carbonization temperature to 80 ° C, and the reaction time is 6 hours to obtain the intermediate product calcium carbonate materials;

[0046] (4) Add deionized calcium carbonate material to the intermediate product and heat it to 85°C, then put it into a stainless s...

Embodiment 3

[0056] The preparation technology of the calcium carbonate of the present embodiment, comprises the following steps:

[0057] (1) adding calcium nitrate to deionized water, dissolving and preparing a calcium nitrate solution with a mass fraction of 50%;

[0058] (2) Add ammonia water to the calcium nitrate solution under the temperature condition of 70° C., under the condition of ensuring pH strong alkalinity, add calcium hydroxide, stir evenly, let stand for 3 hours, and filter to obtain the refined solution;

[0059] (3) Ultrasonic atomize the refined solution into a refined atomized product, and pass the refined atomized product into the carbonization tower, then add ammonium bicarbonate to carry out carbonization reaction, control the carbonization temperature to 75 ° C, and the reaction time is 5 hours to obtain the intermediate product calcium carbonate materials;

[0060] (4) Add deionized calcium carbonate material to the intermediate product and heat it to 80°C, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com