Mildew-proof and fresh-keeping coated paper and processing method thereof

A technology of coating paper and anti-mildew coating, applied in anti-biological reagent addition, paper, papermaking, etc., can solve the problem of short duration of anti-mildew effect, achieve good water and oxygen barrier, avoid damage, and delay oxidative deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

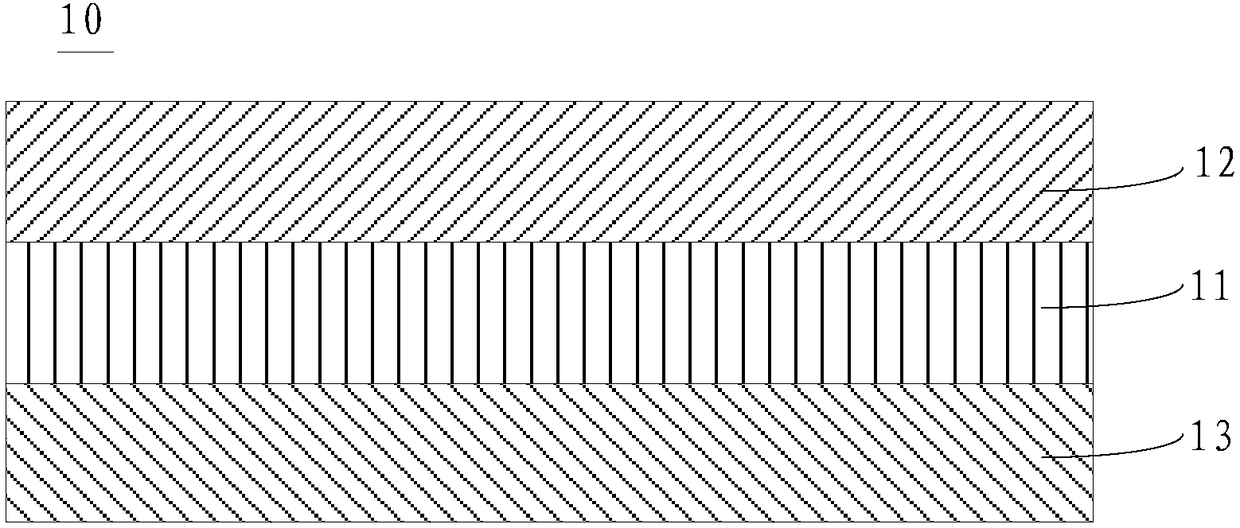

Image

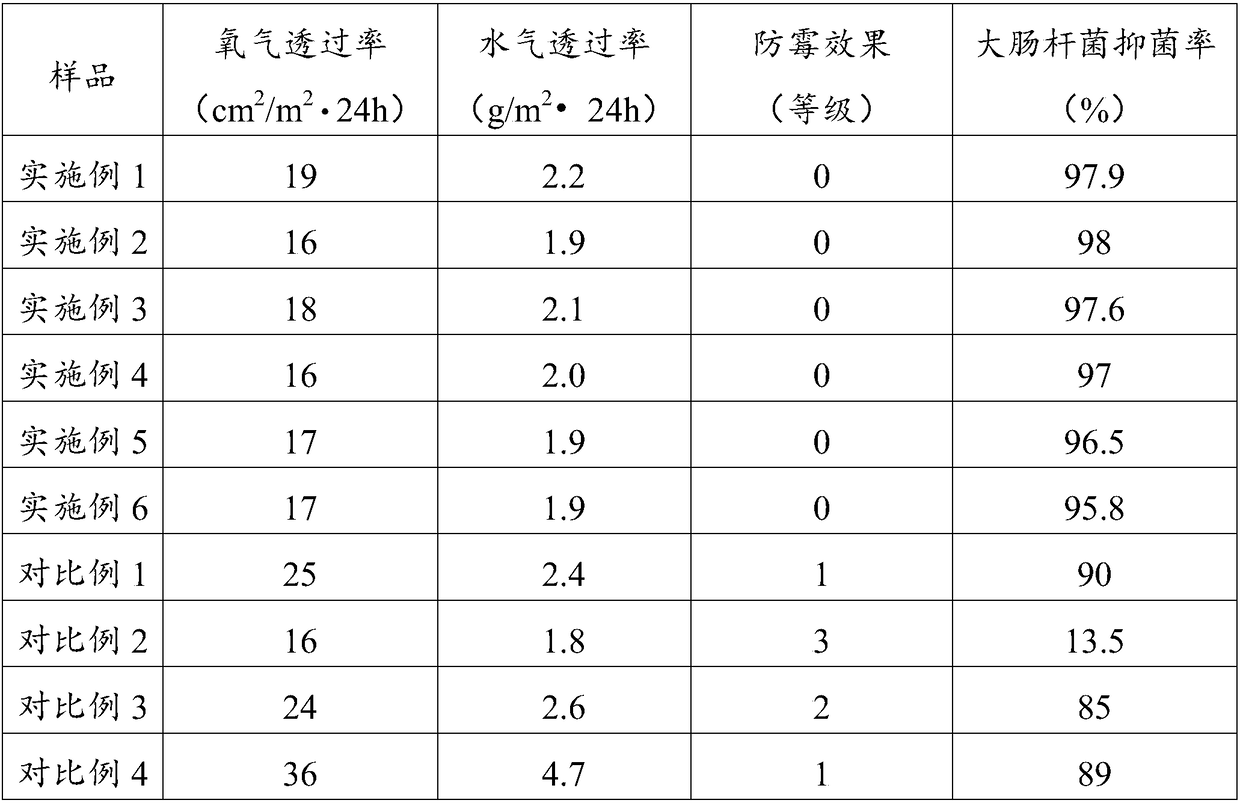

Examples

Embodiment 1

[0053] Mix 50 parts of polyvinylidene chloride emulsion and 10 parts of ethylene-vinyl acetate copolymer emulsion, add 0.5 part of emulsifier and 0.05 part of defoamer, stir at 50 rpm for 30 minutes, mix well, add 1 part of isocyanate was stirred at 80 rpm for 30 minutes, and 5 parts of microencapsulated antifungal agents were added, wherein the microencapsulated antifungal agents were ethylparaben, Kathon, Nano-titanium dioxide composite-chitosan microcapsules, after stirring and dispersing evenly, the anti-mildew and fresh-keeping coating can be obtained.

[0054] Press the anti-mold coating to 6g / m 2 coated on the surface of the base paper, and then treated at 80°C, 90°C, 110°C, 120°C and 90°C for 1.5s respectively to form an anti-mold and fresh-keeping coating, and the anti-mold and fresh-keeping coated paper was obtained.

Embodiment 2

[0056] Mix 50 parts of polyvinylidene chloride emulsion and 10 parts of ethylene-vinyl acetate copolymer emulsion, add 0.5 part of emulsifier and 0.05 part of defoamer, stir at 50 rpm for 30 minutes, mix well, add 1 part of isocyanate was stirred at 80 rpm for 30 minutes, and 5 parts of microencapsulated antifungal agents were added, wherein the microencapsulated antifungal agents were ethylparaben, Kathon, Nano-titanium dioxide composite-chitosan microcapsules, after stirring and dispersing evenly, the anti-mildew and fresh-keeping coating can be obtained.

[0057] Press the anti-mold coating to 6g / m 2 coated on the surface of the base paper, and then treated at 80°C, 90°C, 110°C, 120°C and 90°C for 1.5s respectively to form an anti-mold and fresh-keeping coating, and the anti-mold and fresh-keeping coated paper was obtained.

Embodiment 3

[0059] Mix 50 parts of polyvinylidene chloride emulsion and 10 parts of ethylene-vinyl acetate copolymer emulsion, add 0.5 part of emulsifier and 0.05 part of defoamer, stir at 50 rpm for 30 minutes, mix well, add 1 part of isocyanate was stirred at 80 rpm for 30 minutes, and 5 parts of microencapsulated antifungal agents were added, wherein the microencapsulated antifungal agents were ethylparaben, Kathon, Nano-titanium dioxide composite-chitosan microcapsules, after stirring and dispersing evenly, the anti-mildew and fresh-keeping coating can be obtained.

[0060] Press the anti-mold coating to 6g / m 2 coated on the surface of the base paper, and then treated at 80°C, 90°C, 110°C, 120°C and 90°C for 1.5s respectively to form an anti-mold and fresh-keeping coating, and the anti-mold and fresh-keeping coated paper was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com