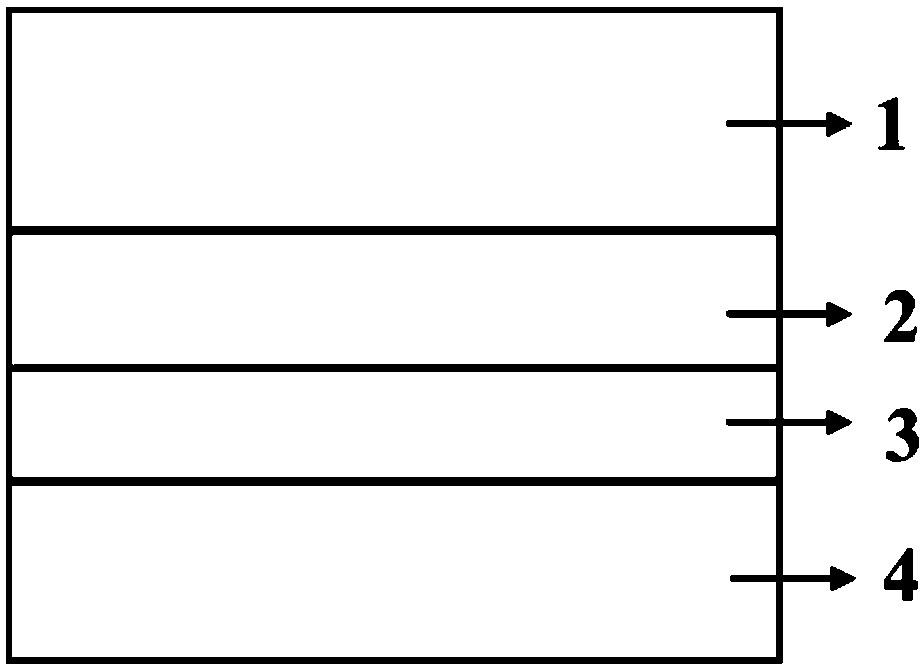

High-efficiency planar heterojunction perovskite thin film solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems that restrict the commercialization process of perovskite solar cell efficiency, and achieve improved light absorption capacity, improved contact conditions, and tight contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

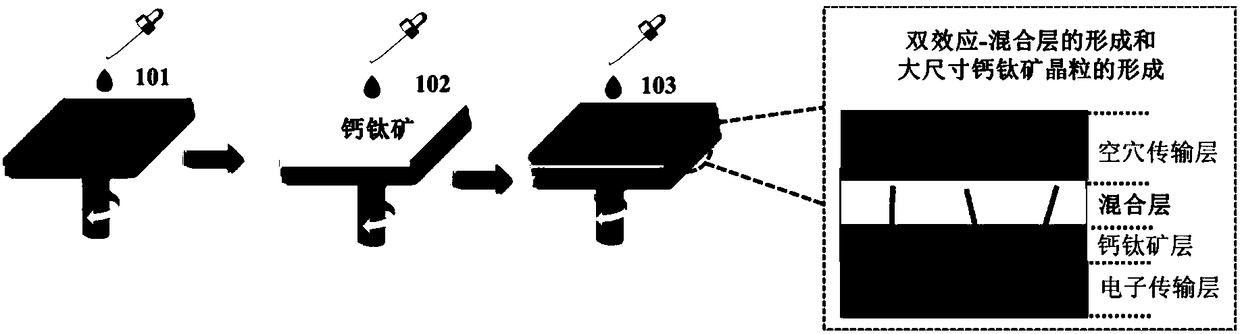

Method used

Image

Examples

Embodiment 1

[0028] 1) Treatment of ITO glass: first, clean the ITO glass with a size of 15mm×15mm and an impedance of 10Ω / sq with detergent powder, then ultrasonically treat it in deionized water, absolute ethanol and acetone for 15 minutes, and then UV treatment of ITO glass for 15 minutes;

[0029] 2) Spin coating of the electron transport layer: firstly, the prepared TiO 2 The solution was spin-coated on the ITO glass treated in step 1) at 4000 rpm for 60 seconds, then annealed in air at 150°C for 10 minutes, and slowly cooled to room temperature to obtain dense TiO 2 layer;

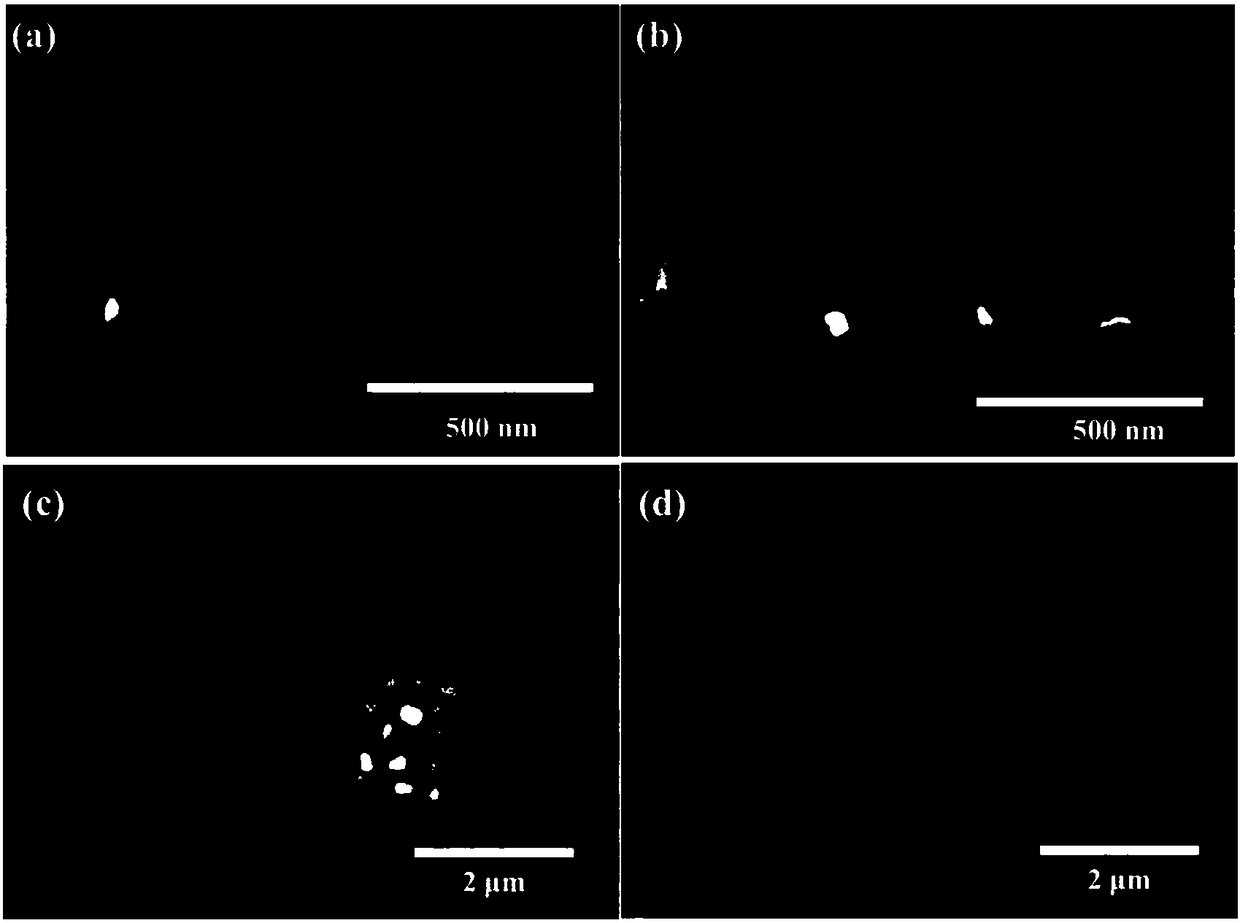

[0030] 3) Spin-coating of perovskite light-absorbing layer: Put the above-mentioned ITO glass treated in step 2) into a glove box. Take equimolar ratio of CH 3 NH 3 I and PbI 2 Add it into a mixed solvent of γ-butyrolactone and DMSO with a volume ratio of 7:3 and stir well to obtain a perovskite precursor solution. Then drop the perovskite precursor solution on the TiO 2 On the layer, spin-coat at a rate o...

Embodiment 2

[0035] 1) Treatment of ITO glass: first, clean the ITO glass with a size of 15mm×15mm and an impedance of 10Ω / sq with detergent powder, then ultrasonically treat it in deionized water, absolute ethanol and acetone for 15 minutes, and then UV treatment of ITO glass for 15 minutes;

[0036] 2) Spin coating of the electron transport layer: firstly, the prepared TiO 2 The solution was spin-coated on the ITO glass treated in step 1) at a rate of 4000 rpm for 60 seconds, then annealed in air at 150°C for 10 minutes, and finally cooled slowly to room temperature to obtain dense TiO 2 layer;

[0037] 3) Spin-coating of perovskite light-absorbing layer: Put the above-mentioned ITO glass treated in step 2) into a glove box. Take equimolar ratio of CH 3 NH 3 I and PbI 2 Add it into a mixed solvent of γ-butyrolactone and DMSO with a volume ratio of 7:3 and stir well to obtain a perovskite precursor solution. Then drop the perovskite precursor solution on the TiO 2 On the layer, spi...

Embodiment 3

[0042] 1) Treatment of ITO glass: first, clean the ITO glass with a size of 15mm×15mm and an impedance of 10Ω / sq with detergent powder, then ultrasonically treat it in deionized water, absolute ethanol and acetone for 15 minutes, and then UV treatment of ITO glass for 15 minutes;

[0043] 2) Spin coating of the electron transport layer: firstly, the prepared TiO 2 The solution was spin-coated on the ITO glass treated in step 1) at a rate of 4000 rpm for 60 seconds, then annealed in air at 150°C for 10 minutes, and slowly cooled to room temperature to obtain dense TiO 2 layer;

[0044] 3) Spin-coating of perovskite light-absorbing layer: Put the above-mentioned ITO glass treated in step 2) into a glove box. Take equimolar ratio of CH 3 NH 3 I and PbI 2 Add it into a mixed solvent of γ-butyrolactone and DMSO with a volume ratio of 7:3 and stir well to obtain a perovskite precursor solution. Then drop the perovskite precursor solution on the TiO 2 On the layer, spin-coat a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com