Preparation method of environment-friendly plasticizer dioctyl terephthalate

A technology of dioctyl phthalate and terephthalic acid, which is applied in the field of preparation of environmentally friendly plasticizer dioctyl terephthalate, can solve the problems of long production process and high energy consumption, and achieve the catalyst dosage Less, high esterification conversion rate, mild reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

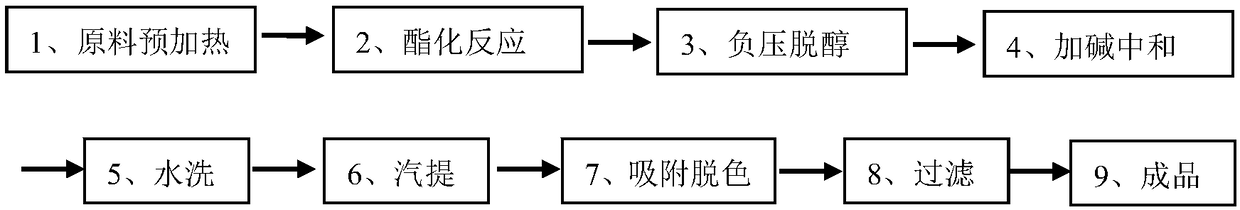

Method used

Image

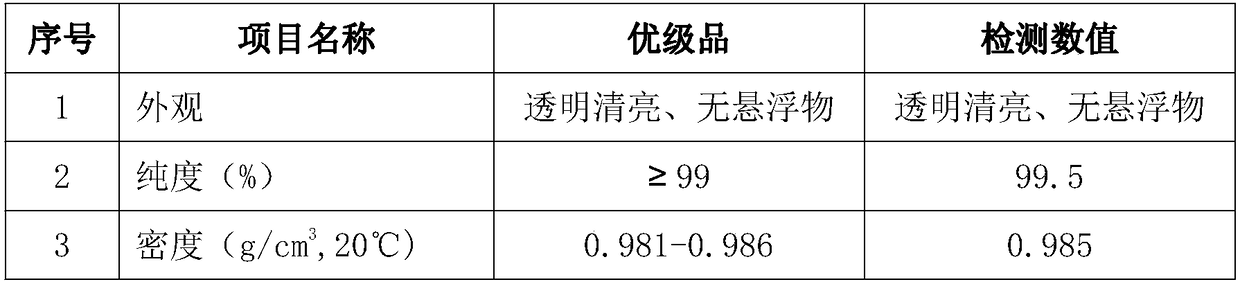

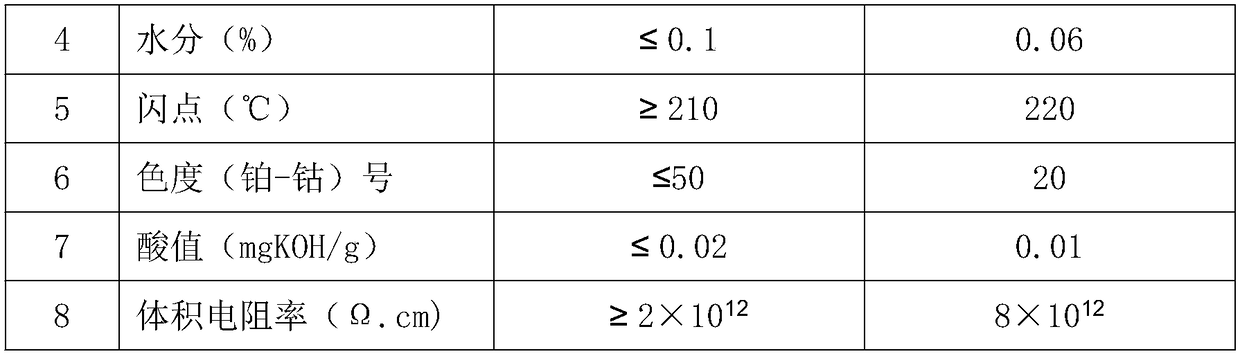

Examples

Embodiment 1

[0026] 1. Esterification reaction

[0027] Put 2500kg of raw material isooctyl alcohol into a 4000L stainless steel kettle with stirring and pressure resistance, start stirring and heat up to 165-175°C to remove the moisture contained in the material.

[0028] In a 5000L stainless steel esterification reaction kettle with stirring and pressure resistance, 875kg of preheated isooctyl alcohol is put into it at one time, the stirring is started, and then 1000kg of terephthalic acid is put into it, and the lid of the kettle is closed.

[0029] Turn on the steam to heat up the temperature, and at the same time, pass a small amount of nitrogen into the material in the tank from the bottom of the esterification reaction tank for bubbling to prevent the material from settling. , when the temperature in the kettle is 200-220°C and the pressure is 0.01-0.03MPa, start to drop the remaining 1625kg of isooctyl alcohol in the preheating kettle, and the time to complete the dropwise addition...

Embodiment 2

[0036] 1. Esterification reaction

[0037] Put 2,800kg of raw material isooctyl alcohol into a stirred, pressure-resistant 4,000L stainless steel kettle, start stirring and heat up to 165-175°C to remove the moisture contained in the material.

[0038] Put 980kg of preheated isooctyl alcohol into a 5000L stainless steel esterification reaction kettle with stirring and pressure resistance at one time, start stirring, then put in 1000kg of terephthalic acid, and close the lid of the kettle.

[0039]Turn on the steam to heat up the temperature, and at the same time, pass a small amount of nitrogen into the material in the tank from the bottom of the esterification reactor for bubbling to prevent the material from settling. , when the temperature in the kettle is 200-220°C and the pressure is 0.01-0.03MPa, start to add dropwise the remaining 1820kg of isooctyl alcohol in the preheating kettle, and the time to complete the dropwise addition is 1.1h. After the dropwise addition of i...

Embodiment 3

[0046] 1. Esterification reaction

[0047] Put 3,200kg of raw material isooctyl alcohol into a stirred, pressure-resistant 4,000L stainless steel kettle, start stirring and heat up to 165-175°C to remove the moisture contained in the material.

[0048] 1120kg of preheated isooctyl alcohol is put into a 5000L stainless steel esterification reaction kettle with stirring and pressure resistance at one time, the stirring is started, and then 1000kg of terephthalic acid is put into it, and the lid of the kettle is closed.

[0049] Turn on the steam to heat up the temperature, and at the same time, pass a small amount of nitrogen into the material in the tank from the bottom of the esterification reaction tank for bubbling to prevent the material from settling. , when the temperature in the kettle is 200-220°C and the pressure is 0.01-0.03MPa, start to add dropwise the remaining 2082kg of isooctyl alcohol in the preheating kettle, and the time to complete the dropwise addition is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com