Odor removing impact bar for closure of elevator car door

A buffer strip and car door technology, applied in the field of elevator materials, can solve the problems of not being able to remove the elevator odor well, the safety touch panel is not adjusted properly, and the elevator air quality is poor, so as to achieve high practical value, increase plasticity, and reduce noise and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

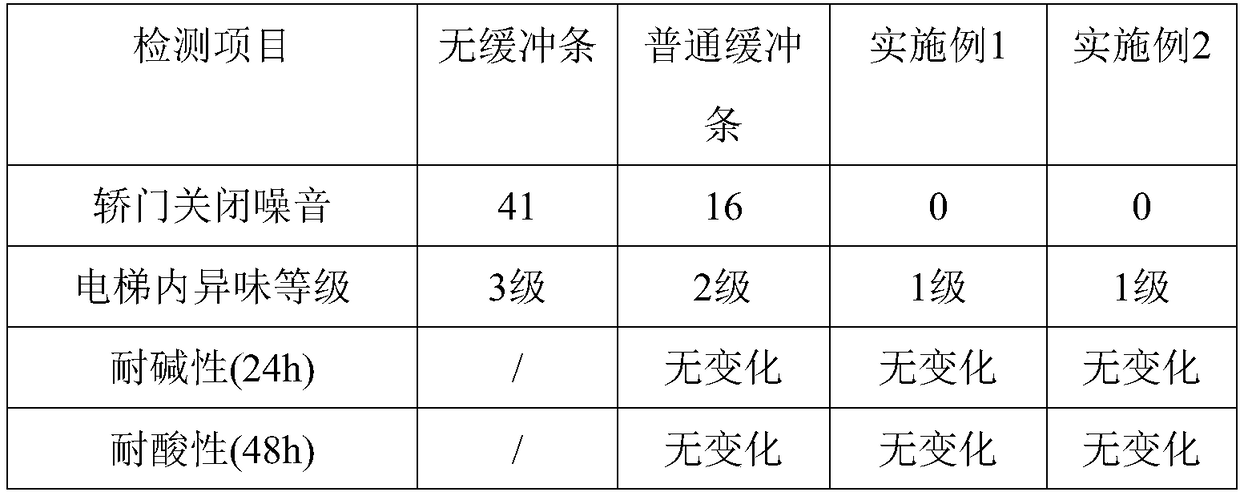

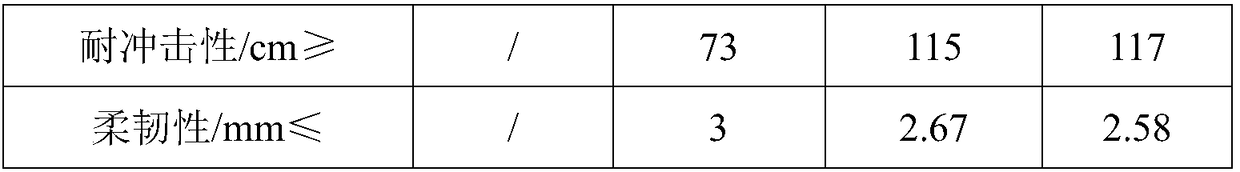

Examples

Embodiment 1

[0038] A deodorizing buffer strip and its preparation method;

[0039] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0040] An elevator car door closing deodorizing buffer strip, including specific technical solutions as follows: The elevator car door closing deodorizing buffer strip provided by the present invention includes the following components by mass: 11 parts of ligninase, 10 parts of light calcium carbonate, 17 parts of antimony trioxide, 14 parts of camphor, 12 parts of stearic acid, 9 parts of salicylic acid, 30 parts of pottery clay, 12.5 parts of easy-mix tank black, 0.5 parts of foam regulator DLF, 15 parts of aromatic essential oil, aloe vera gel 5 parts, 10 parts of diatom mud, 15 parts of activated carbon, 6 parts of nano-modified alkyd resin, 1.5 parts of impact modifier ACM, 1 part of polyethylene wax, 0.6 parts of stearic acid, 1.5 parts of anti-aging agent, 27 parts of butyl rubber, 6 p...

Embodiment 2

[0059] A kind of elevator car door closing deodorization buffer strip;

[0060] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0061] A kind of preparation method of elevator car door closure deodorization buffer strip of the present invention comprises the following steps:

[0062] (1) butyl rubber and nano-modified alkyd resin are added in the mixed acid solution of 85 times of its weight, and described mixed acid is made up of 60% carbonic acid and 87% hydrochloric acid solution with a mass ratio of 3.5:1, Sonicate at 50°C for 18 minutes, filter, wash the precipitate twice with water, and dry in vacuum at 70°C for 30 minutes to obtain acidified modified butylpyroxene rubber;

[0063] (2) Get 47% of the weight of the above-mentioned acidified modified butylpyridine rubber, mix it with easy-to-mix tank black, foam regulator DLF, aromatic essential oil, aloe gel, diatom ooze, and antimony trioxide, and add to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com