Preparation method of window screen coating for air purification

A technology of air purification and window screen, which is applied in the field of window screen coating preparation, can solve the problems such as the difficulty of cleaning the screen window mesh, achieve low friction coefficient, eliminate difficult cleaning, and reduce the friction coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

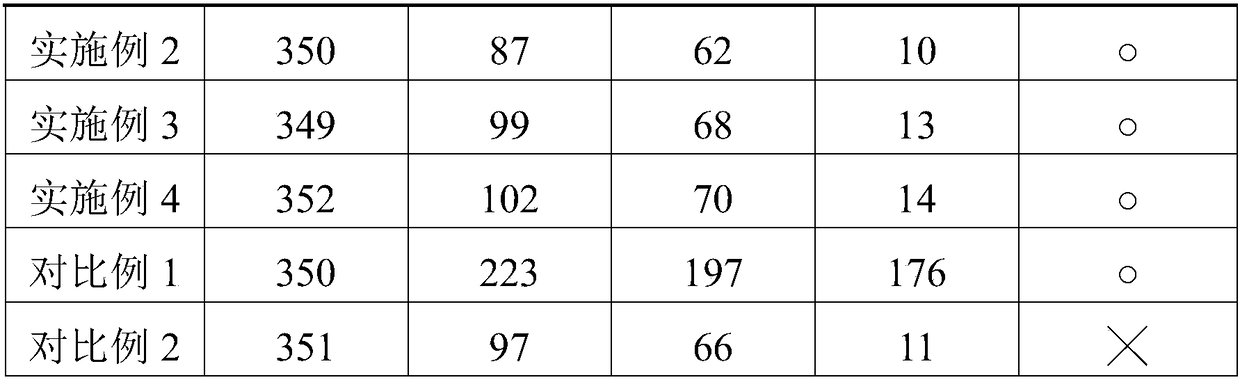

Examples

Embodiment 1

[0027] A kind of preparation method of the window screen coating that is used for air purification:

[0028] (1) 800g monomer 3-ethyl-3-butoxetanol is dissolved in the ethanol of 1200g, add 10g initiator boron trifluoride ether, 100g tetraethyl titanate, 130g zinc chloride and 50g kaolin ( The particle size is 8 μm), flowing at a temperature of 55°C for 8h to obtain a reaction mixture, and then adding 50g of precipitant ion water for precipitation, drying the precipitate at 100°C under vacuum to constant weight, and then raising the temperature to 280°C to continue calcining for 2h, Obtain modified hyperbranched polyether;

[0029] (2) The modified hyperbranched polyether in step (1) and 100g colloidal graphite powder (purchased from Qingdao Ouer Graphite Co., Ltd., the trade mark is Oer-F00, and the particle size is 1 μm) are added in a high-speed mixer and mixed, Then be dispersed in 2000g solvent-type thermosetting acrylic resin (purchased from Japan DIC company), be equip...

Embodiment 2

[0031] A kind of preparation method of the window screen coating that is used for air purification:

[0032] (1) Dissolve 780g of monomer 3-ethyl-3-butoxanemethanol in 1170g of toluene, add 10g of initiator boron trifluoride ether, 90g of tetrapropyl titanate, 80g of zinc nitrate and 40g of kaolin (grain diameter of 5 μm), reflux at a temperature of 53°C for 6 hours to obtain a reaction mixture, then add 40 g of precipitant anhydrous ether for precipitation, dry the precipitate at 100°C under vacuum to constant weight, then raise the temperature to 280°C and continue calcining for 2 hours , to obtain modified hyperbranched polyether;

[0033] (2) The modified hyperbranched polyether in step (1) and 90g colloidal graphite powder (purchased from Qingdao Ouer Graphite Co., Ltd., the trade mark is Oer-F0, and the particle size is 2 μm) are added in a high-speed mixer and mixed, Then be dispersed in 1840g solvent-type thermosetting acrylic resin (purchased from Japan DIC company),...

Embodiment 3

[0035] A kind of preparation method of the window screen coating that is used for air purification:

[0036] (1) 720g monomer 3-ethyl-3-butoxetanol is dissolved in the xylene of 864g, adds 5g initiator boron trifluoride ether, 30g tetraethyl titanate, 50g zinc nitrate and 30g kaolin ( The particle size is 3 μm), reflux at 50°C for 10 hours to obtain the reaction mixture, then add 30 g of precipitant ion water for precipitation, dry the precipitate at 100°C under vacuum to constant weight, and then raise the temperature to 270°C to continue calcining for 3 hours , to obtain modified hyperbranched polyether;

[0037](2) The modified hyperbranched polyether in step (1) and 50g colloidal graphite powder (purchased from Qingdao Ouer Graphite Co., Ltd., the trade mark is Oer-F1, and the particle diameter is 4 μm) is added in the high-speed mixer and mixed, Then be dispersed in 1750g solvent-type thermosetting acrylic resin (purchased from Japan DIC company), be equipped with 5250g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com