Preparation method of non-metal reinforcer

A technology of non-metallic reinforcement and metal reinforcement is applied in the field of preparation of optical cable reinforcement to achieve the effects of good tensile strain performance, improved high-strength resistance to yield tension and small bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

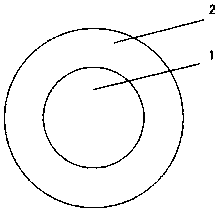

[0021] Such as figure 1 A non-metallic reinforcing member as shown comprises a glass fiber 1 arranged in the center and a carbon-bonded non-metallic bonding layer 2 coated outside the glass fiber 1, the cross section of which is circular, and its preparation method comprises steps

[0022] (1) Feed: first place the glass fiber of the corresponding specification on the pay-off rack, pass the lead wire through a mold with a hole diameter of 0.50mm, a length of 480mm and a width of 200mm, bypass the traction, tighten the wire and fix it on the plastic disk;

[0023] (2) Soaking: Immerse the glass fiber in the impregnating solution for 10-20 minutes. The impregnating solution is prepared from the following components in weight percent: graphite 3.8%, resin 18%, calcium carbonate 6.5%, stearic acid 8.5% zinc, 16.2% aluminum hydroxide, 8.5% sulphate, 9.2% PE powder, 12% release agent, 17.3% resin sizing agent;

[0024] (3) Drying / curing: introduce the glass fiber into the mold at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com