A kind of ceramic matrix composite solid electrolyte and preparation method thereof

A solid electrolyte, ceramic matrix composite technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of poor interface contact, poor mechanical properties, low lithium ion conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

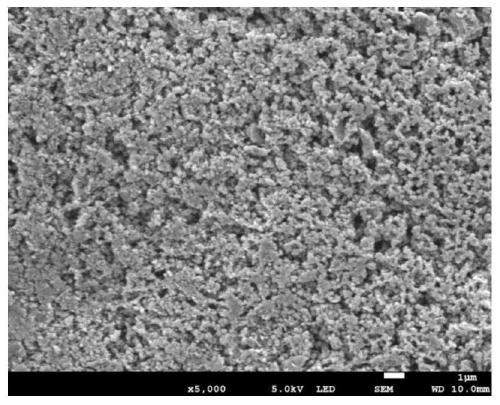

[0037] A ceramic matrix composite solid electrolyte, the composite solid electrolyte includes Li1+xAlxTi2-x(PO4)3, polyvinylidene fluoride, lithium perchlorate and gel electrolyte, its thickness is 10-150μm, room temperature ionic conductivity is 1 *10 -4 S / cm~1*10 -3 S / cm, the electrochemical window is greater than 5.0V.

[0038] The mass proportion of Li1+xAlxTi2-x(PO4)3 in the composite solid electrolyte is 80%.

[0039] The mass proportion of polyvinylidene fluoride in the composite solid electrolyte is 5%.

[0040] The mass proportion of lithium perchlorate in the composite solid electrolyte is 10%.

[0041] The gel electrolyte contains polyethylene glycol diacrylate, electrolyte, methacryloxypropyltrimethoxysilane and azobisisobutyronitrile, and the mass ratio of the gel electrolyte in the composite solid electrolyte is 5% ;

[0042] Wherein, polyethylene glycol diacrylate accounts for 3% by mass in the gel electrolyte.

[0043] The mass ratio of methacryloxypropyl...

Embodiment 2

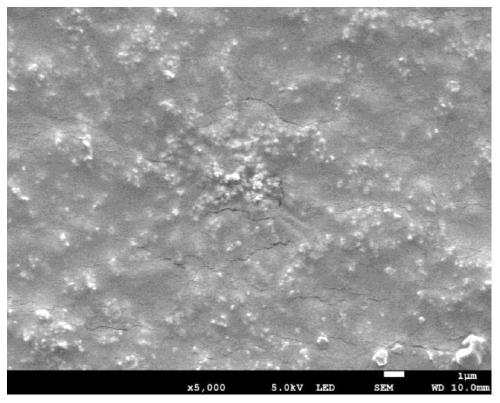

[0058] A ceramic-based composite solid electrolyte, the composite solid electrolyte includes Li7La3Zr2O12, polyvinylidene fluoride-hexafluoropropylene, bis(trifluoromethylsulfonate)imide lithium and gel electrolyte, its thickness is 10-150μm, room temperature ionic The conductivity is 1*10 -4 S / cm~1*10 -3 S / cm, the electrochemical window is greater than 5.0V.

[0059] The mass proportion of Li7La3Zr2O12 in the composite solid electrolyte is 60%.

[0060] The mass proportion of lithium bis(trifluoromethanesulfonate)imide in the composite solid state electrolyte is 20%.

[0061] The mass proportion of vinylidene fluoride-hexafluoropropylene in the composite solid electrolyte is 10%.

[0062] The gel electrolyte includes tetraethylene glycol dimethacrylate, electrolyte, butyl acrylate and azobisisoheptanonitrile, and the mass ratio of the gel electrolyte in the composite solid electrolyte is 10%;

[0063] Wherein, tetraethylene glycol dimethacrylate accounts for 4% by mass in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com