Composite material used for three-dimensional printing of porous tissue scaffold and preparation method thereof

A 3D printing, porous tissue technology, applied in the preparation of 3D printing porous tissue engineering scaffold composite materials, in the field of 3D printing porous tissue engineering scaffold composite materials, can solve the problem of inconvenient industrialization promotion and application, poor controllability of porosity and structure, The preparation process is cumbersome and other problems, and the effect of good osteogenesis, controllable microporous structure and good biocompatibility can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

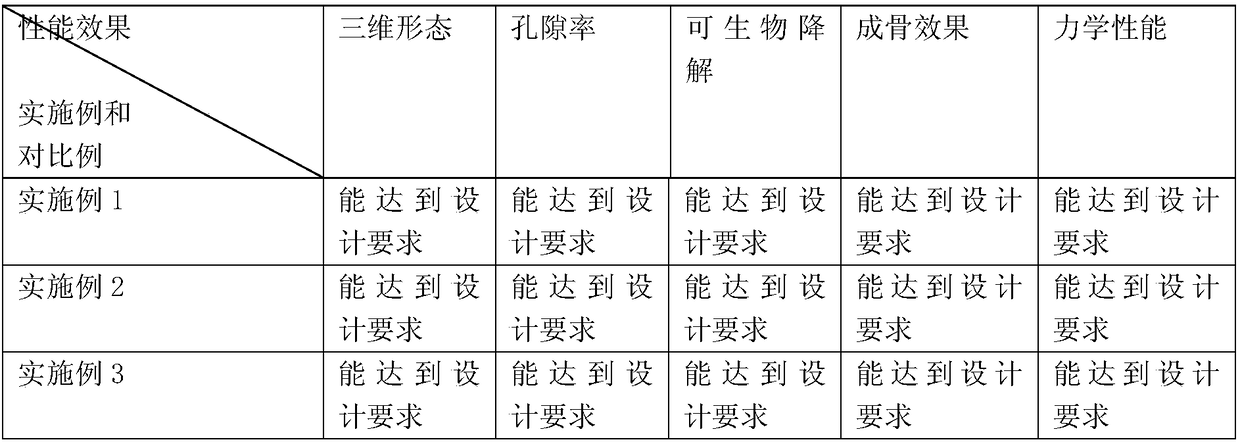

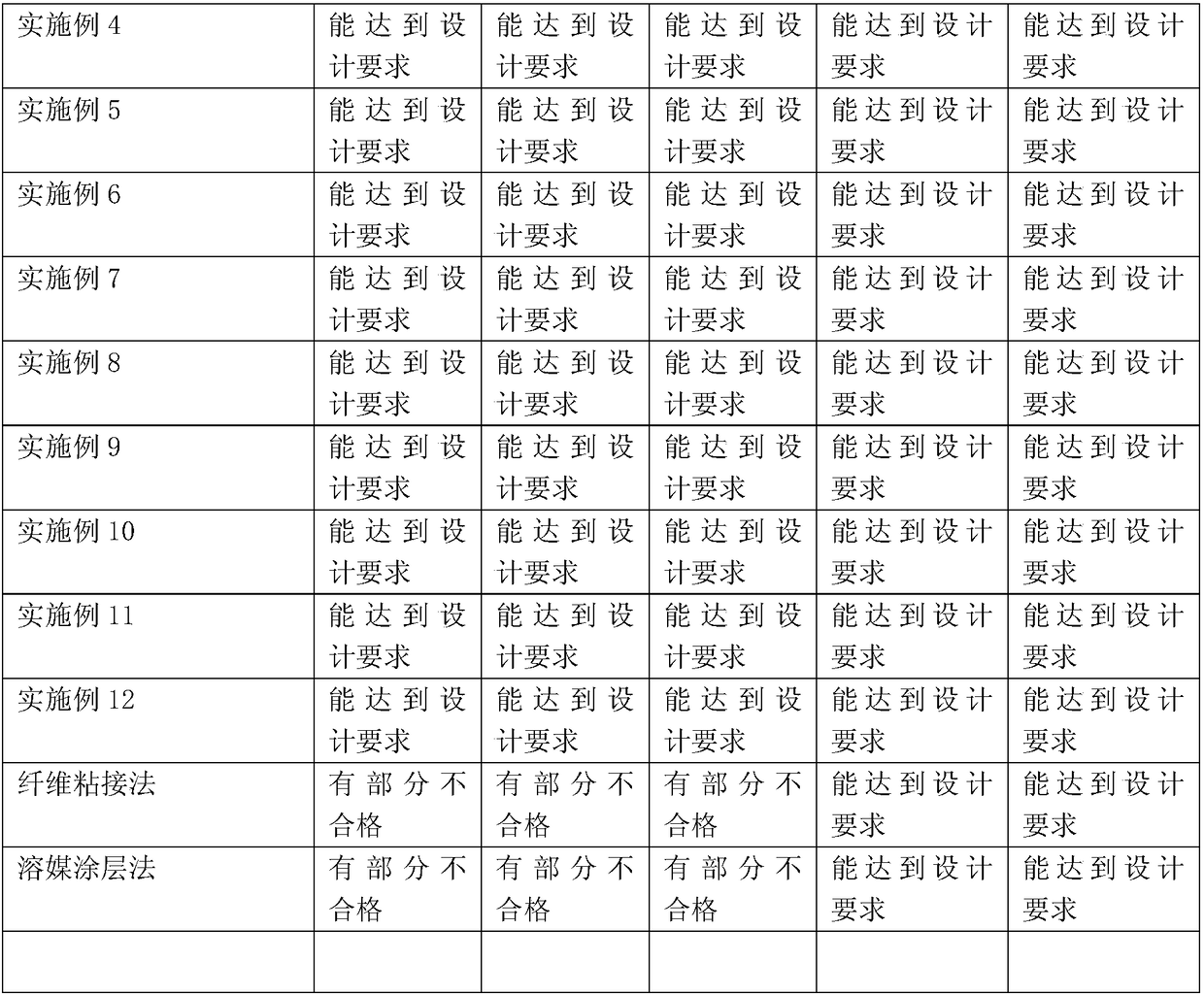

Examples

Embodiment 1

[0058] Embodiment 1: A kind of preparation method of 3D printing porous tissue engineering scaffold composite material of the present invention has the following steps:

[0059] 1) 50 parts of polycaprolactone and 10 parts of bioglass are placed in a container;

[0060] 2) the container is placed in a drying oven to dry and remove moisture;

[0061] 3) blending the dried raw materials in the above step 2) uniformly, the blending includes but not limited to two-step blending method or multi-step blending method;

[0062] 4) immediately obtain standby composite material after blending;

[0063] 5) Prepare the above step 4) standby composite material into silk or powder or granule or block;

[0064] 6) Place the composite material filament or powder or particle or block in step 5) in the material supply device of the 3D printer, and add 10 to the material supply device of the 3D printer at the same time 5 3D printing porous tissue engineering scaffolds can be prepared by heati...

Embodiment 2

[0065] Embodiment 2: A kind of preparation method of 3D printing porous tissue engineering scaffold composite material of the present invention has the following steps:

[0066] 1) 90 parts of polycaprolactone and 50 parts of bioglass are placed in a container;

[0067] 2) the container is placed in a drying oven to dry and remove moisture;

[0068] 3) blending the dried raw materials in the above step 2) uniformly, the blending includes but not limited to two-step blending method or multi-step blending method;

[0069] 4) immediately obtain standby composite material after blending;

[0070] 5) Prepare the above step 4) standby composite material into silk or powder or granule or block;

[0071] 6) Place the composite material filament or powder or particle or block in step 5) in the material supply device of the 3D printer, and add 10 to the material supply device of the 3D printer at the same time 6 3D printing porous tissue engineering scaffolds can be prepared by heati...

Embodiment 3

[0072] Embodiment 3: A kind of preparation method of 3D printing porous tissue engineering scaffold composite material of the present invention has the following steps:

[0073] 1) 70 parts of polycaprolactone and 30 parts of bioglass are placed in a container;

[0074] 2) the container is placed in a drying oven to dry and remove moisture;

[0075] 3) blending the dried raw materials in the above step 2) uniformly, the blending includes but not limited to two-step blending method or multi-step blending method;

[0076] 4) immediately obtain standby composite material after blending;

[0077] 5) Prepare the above step 4) standby composite material into silk or powder or granule or block;

[0078] 6) Place the composite material filament or powder or particle or block in step 5) in the material supply device of the 3D printer, and add 10 to the material supply device of the 3D printer at the same time 6 3D printing porous tissue engineering scaffolds can be prepared by heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com