Preparation method of high-strength ion-responsive lubricating hydrogel

A high-strength, lubricating water technology, applied in the field of ion response, can solve the problems of cartilage tissue physical and chemical properties, wear resistance, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 10.0g of polyvinyl alcohol (molecular weight: 130,000) into a 250mL round bottom flask, add 100.0mL of distilled water, reflux and condense at 90°C for 6 hours under magnetic stirring (1000r / min) to dissolve. Add 0.186 g of glutaraldehyde aqueous solution with a mass fraction of 50%, and adjust the solution to pH=2 with 1 mol / L hydrochloric acid. Transfer the solution into a 50mL centrifuge tube, put it in a water bath at 60°C for 8 hours, wash the prepared polyvinyl alcohol hydrogel in distilled water 6 times, each time for one hour, and wash away the residual glutaraldehyde to obtain polyvinyl alcohol hydrogel .

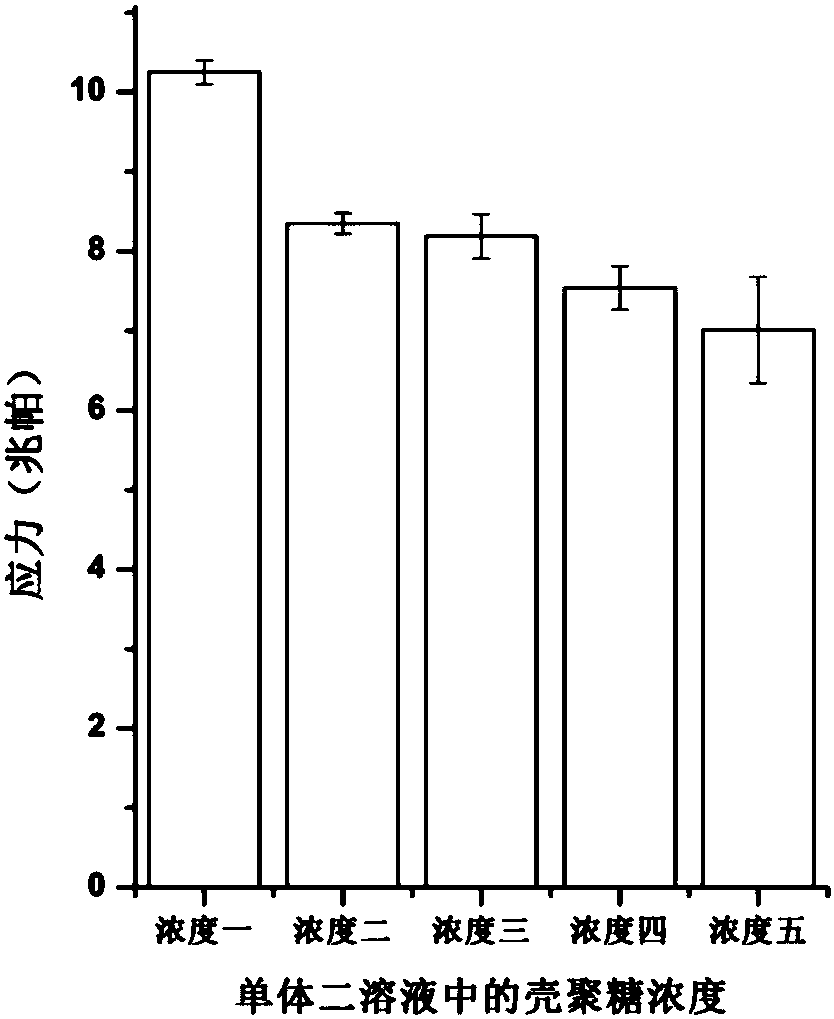

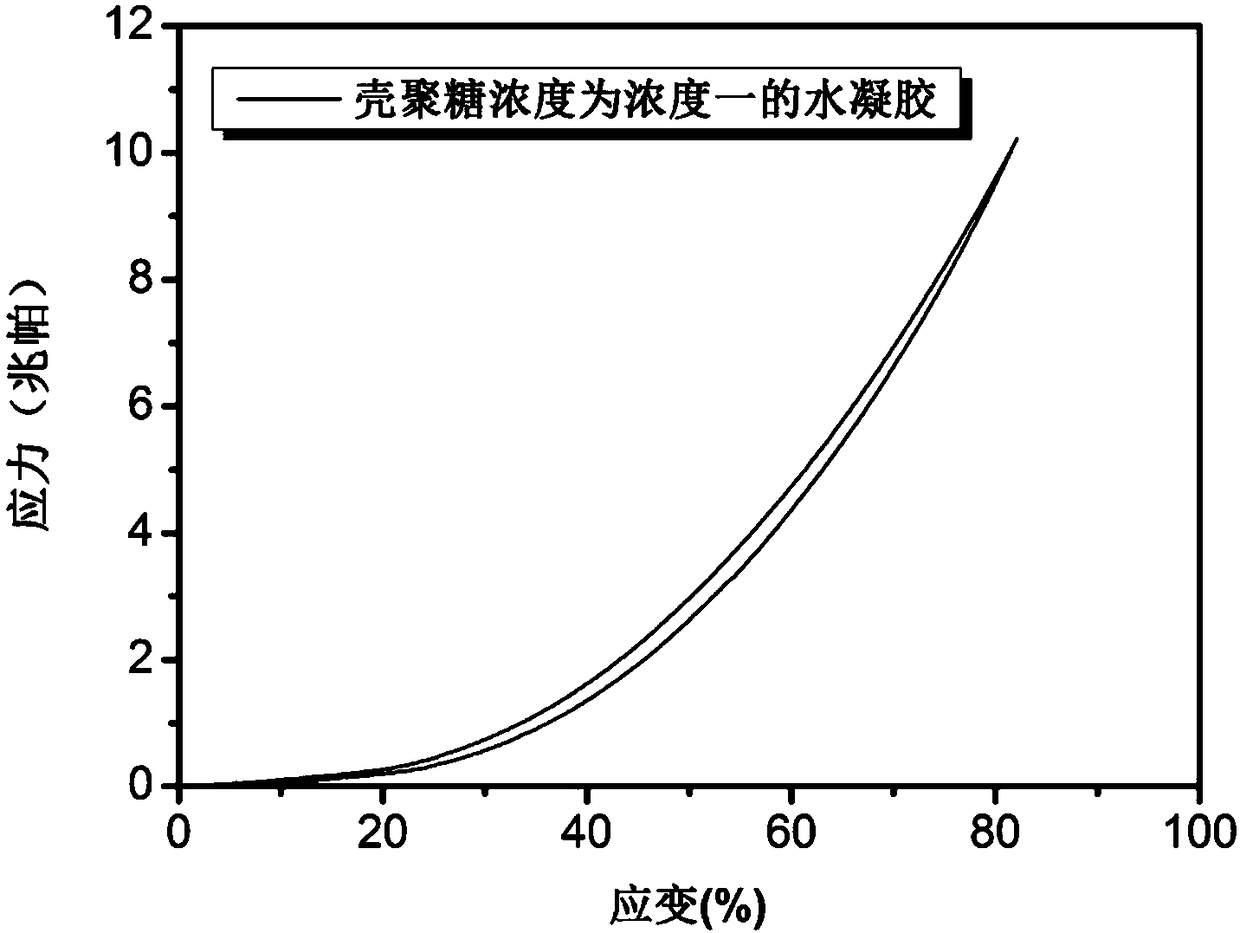

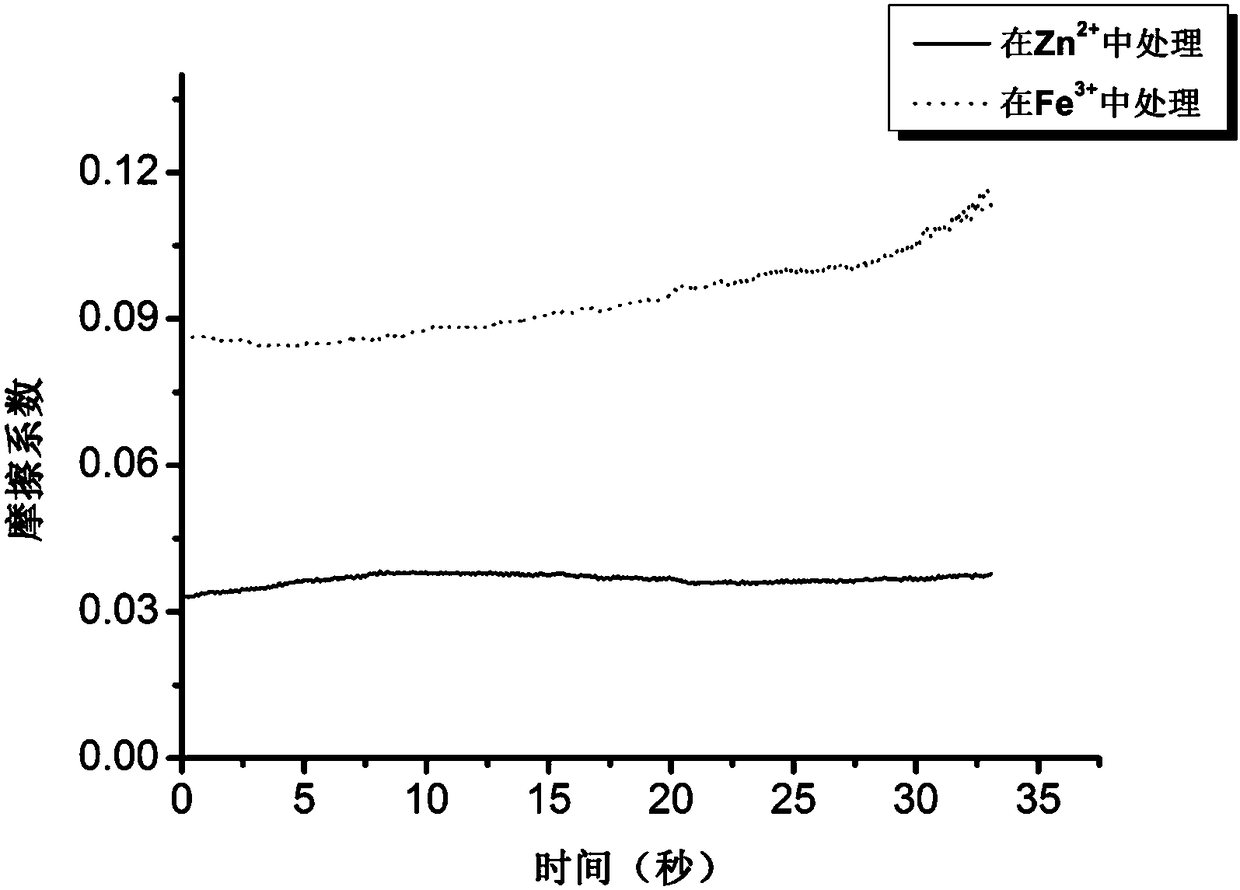

[0021] Weigh 0.02g chitosan and dissolve in 20.0mL, 1mol / L glacial acetic acid aqueous solution to prepare 0.001g / mL chitosan solution; then add 17.0g acrylamide, 0.04g cross-linking agent N,N- Methylbisacrylamide, 0.2g zinc chloride, stirred and dissolved at room temperature to obtain chitosan-acrylamide-zinc chloride solution;

[0022] Place the pr...

Embodiment 2

[0024] Take 20.0g of 2-acrylamido-2-methylpropanesulfonic acid in a 250mL round bottom flask, add 100.0mL of distilled water, and reflux and condense for 1 hour at 25°C under magnetic stirring (1000r / min) to dissolve the solid. Add 0.6 g of N,N-methylenebisacrylamide as a cross-linking agent, and adjust the solution to pH=2 with 1 mol / L hydrochloric acid. The solution was transferred into a 50mL centrifuge tube and placed in a water bath at 60°C for 3 hours to obtain a 2-acrylamido-2-methylpropanesulfonic acid hydrogel. The prepared 2-acrylamido-2-methylpropanesulfonic acid hydrogel was washed 6 times in distilled water, one hour each time, to wash away the residual cross-linking agent.

[0025] Weigh 0.02g chitosan and dissolve in 20.0mL, 1mol / L glacial acetic acid aqueous solution to prepare 0.001g / mL chitosan solution; then add 17.0g acrylamide, 0.04g cross-linking agent N,N- Methylbisacrylamide, 0.2g zinc chloride, stirred and dissolved at room temperature to obtain chito...

Embodiment 3

[0028] Weigh 10.0g of sodium hyaluronate into a 250mL round bottom flask, add 100.0mL of distilled water, reflux and condense at 90°C for 6 hours under magnetic stirring (1000r / min) to dissolve the solid. Add 0.06 g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride as a cross-linking agent, and adjust the solution to pH=2 with 1 mol / L hydrochloric acid. The solution was transferred into a 50mL centrifuge tube and placed in a water bath at 60°C for 6 hours to obtain a sodium hyaluronate hydrogel. The prepared sodium hyaluronate hydrogel was washed 6 times in distilled water, each time for one hour, to wash away the residual cross-linking agent.

[0029] Weigh 0.02g chitosan and dissolve in 20.0mL, 1mol / L glacial acetic acid aqueous solution to prepare 0.001g / mL chitosan solution; then add 17.0g acrylamide, 0.04g cross-linking agent N,N- Methylbisacrylamide, 0.2g zinc chloride, stirred and dissolved at room temperature to obtain chitosan-acrylamide-zinc chloride so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com