Method for preparing graphene-polystyrene composite material by graphene and polystyrene

A composite material, polystyrene technology, applied in the preparation and application of polymer nano-filler composite materials, can solve the problems of high preparation cost, difficult dispersion, uneven dispersion of graphene, etc., and achieve mild conditions, environmental friendliness, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

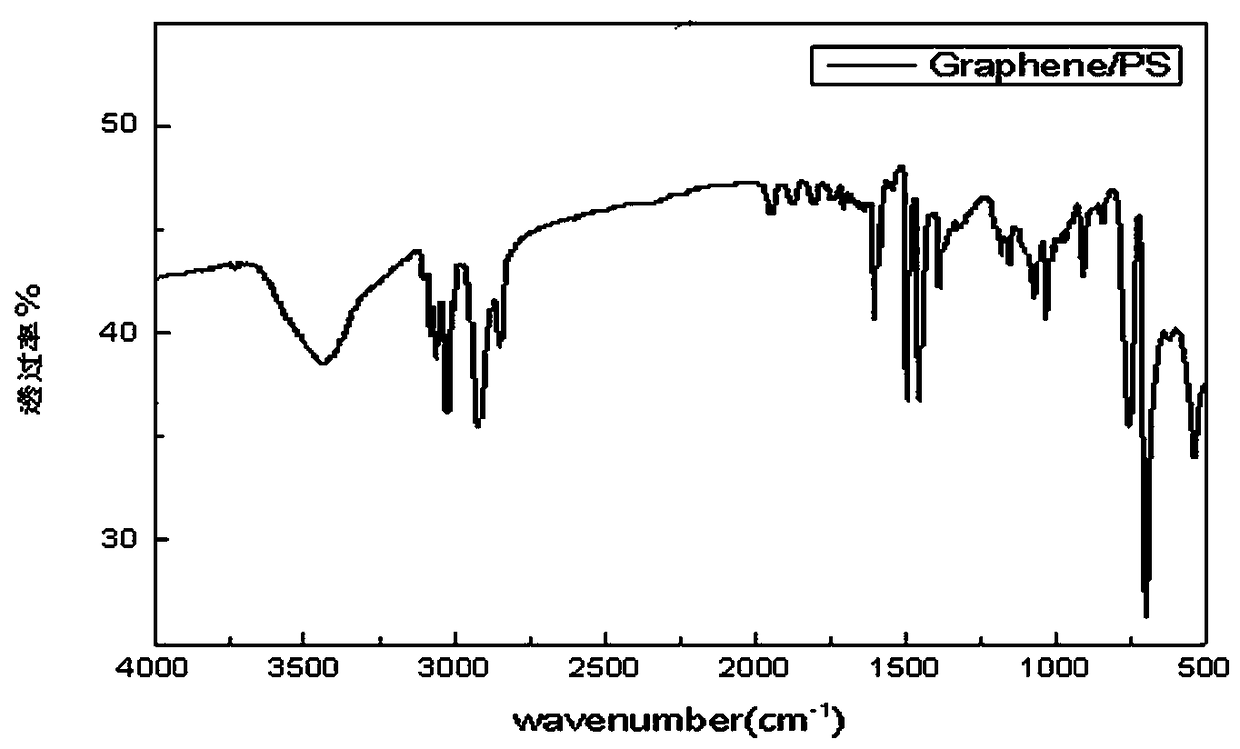

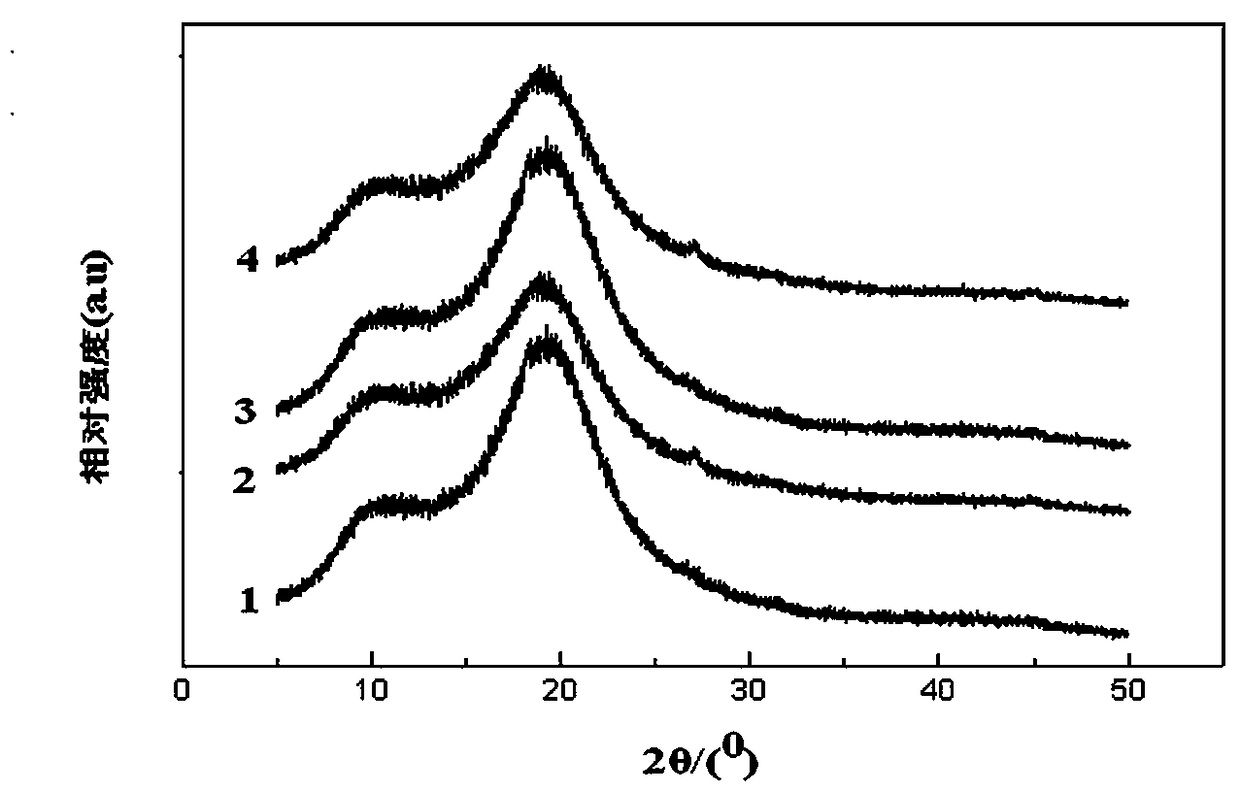

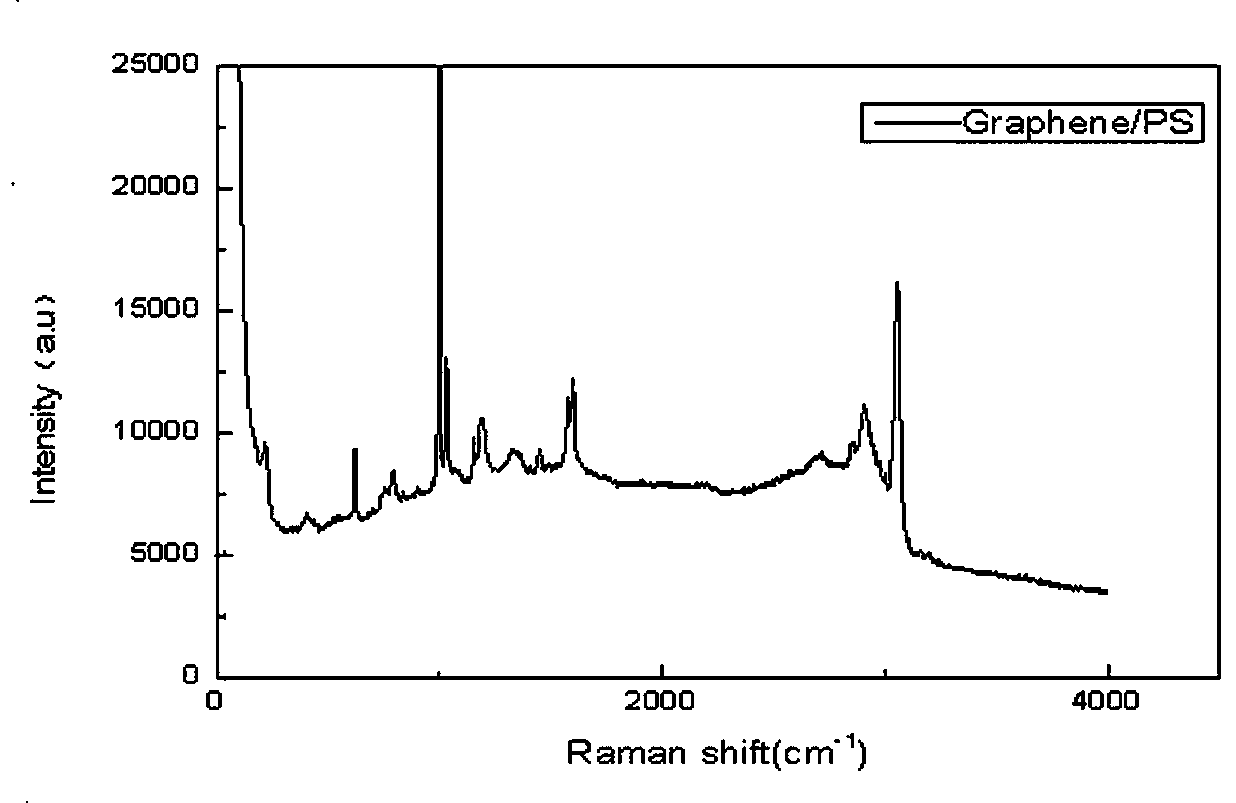

[0019] Example 1 A method for preparing a graphene-polystyrene composite material from graphite and styrene. In the first step, the ratio of the volume of styrene (mL) to the mass (g) of graphite is 1000:1. After mixing styrene and graphite, they are ball-milled in a star-type ball mill for 6 hours to obtain graphene-containing benzene. Ethylene dispersion;

[0020] In the second step, the above-mentioned dispersion of graphene and styrene is placed in a numerically controlled ultrasonic device for ultrasonic dispersion for 2 hours, and further dispersion is carried out to obtain a graphene / styrene dispersion with good dispersibility;

[0021] In the third step, polyvinyl alcohol and deionized water are added into a three-neck reactor equipped with a stirrer and a reflux condenser at a mass ratio of 1:3. The ratio of the volume of the combined solution (mL) to azobisisobutyronitrile (g) is 80:1, add it into the reactor, stir at a stirring speed of 420 r / min, raise the tempera...

Embodiment 2

[0030] Example 2 A method for preparing a graphene-polystyrene composite material from graphite and styrene. In the first step, the ratio of the volume of styrene (mL) to the mass (g) of graphite is 1000:3. After mixing styrene and graphite, they are ball-milled and peeled off in a planetary ball mill for 12 hours to obtain graphene-containing styrene. Dispersions;

[0031]In the second step, the above-mentioned dispersion of graphene and styrene is placed in a numerically controlled ultrasonic device for ultrasonic dispersion for 4 hours, and further dispersion is carried out to obtain a graphene / styrene dispersion with good dispersibility;

[0032] In the third step, polyvinyl alcohol and deionized water are added into a three-neck reactor equipped with a stirrer and a reflux condenser at a mass ratio of 1:3. The ratio of the volume of the combined solution (mL) to azobisisobutyronitrile (g) is 80:1, add it into the reactor, stir at a stirring speed of 420 r / min, raise the ...

Embodiment 3

[0034] Example 3 A method for preparing a graphene-polystyrene composite material from graphite and styrene. In the first step, the ratio of the volume of styrene (mL) to the mass (g) of graphite is 1000:5. After mixing styrene and graphite, they are ball-milled in a star-type ball mill for 24 hours to obtain graphene-containing benzene. Ethylene dispersion;

[0035] In the second step, the above-mentioned dispersion of graphene and styrene is placed in a numerically controlled ultrasonic device for ultrasonic dispersion for 6 hours, and further dispersion is carried out to obtain a graphene / styrene dispersion with good dispersibility;

[0036] In the third step, polyvinyl alcohol and deionized water are added to a three-neck reactor equipped with a stirrer and a reflux condenser at a mass ratio of 1:3. When the water bath is heated to 70°C, graphene and styrene are dispersed. The ratio of the volume of liquid (mL) to azobisisobutyronitrile (g) is 80:1, add it into the reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com