Surface plasmon photocatalyst with broad spectrum absorption and preparation method thereof

A surface plasmon and photocatalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low photocatalytic efficiency and low utilization rate constraints, and achieve enhanced electric field Intensity, promotion of generation and separation, effect of enhancing photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

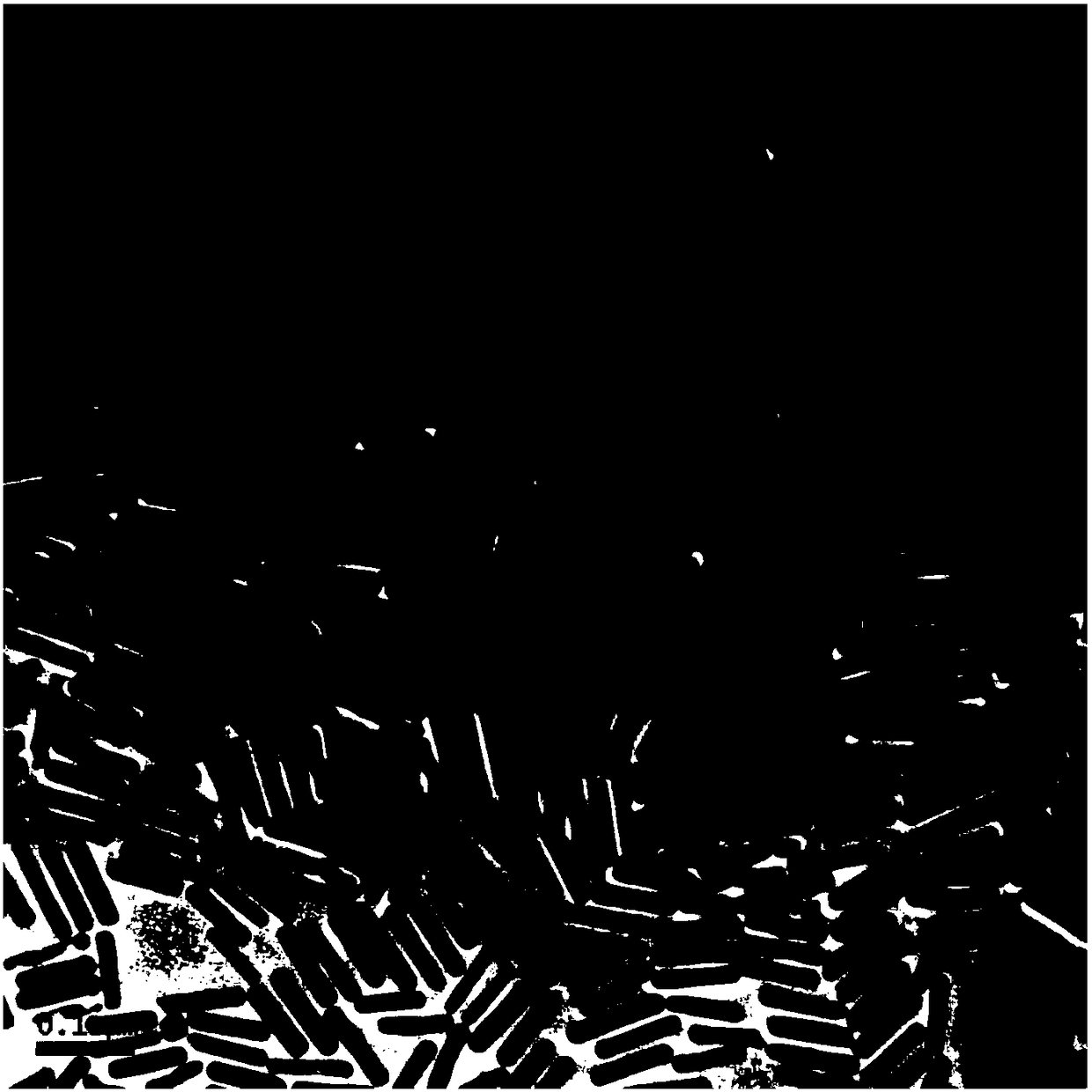

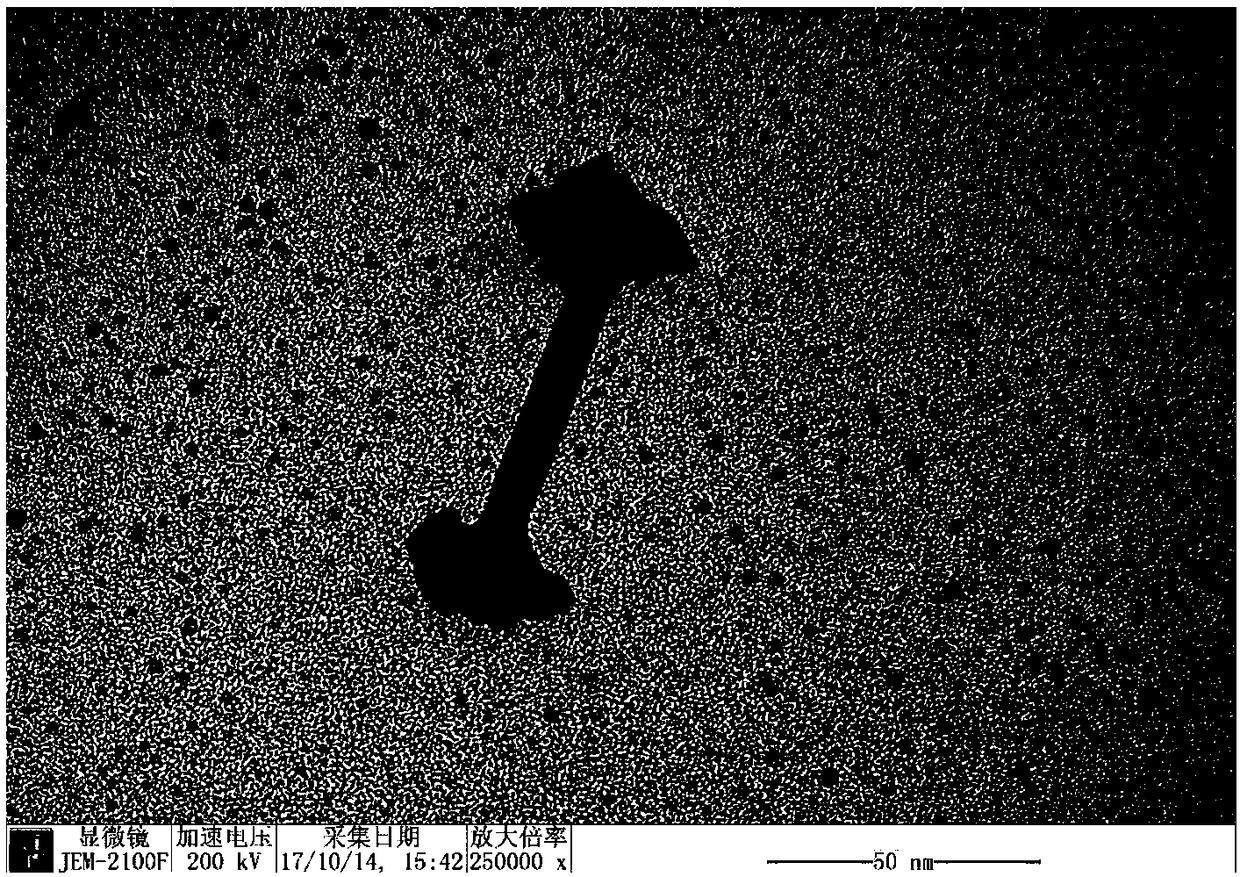

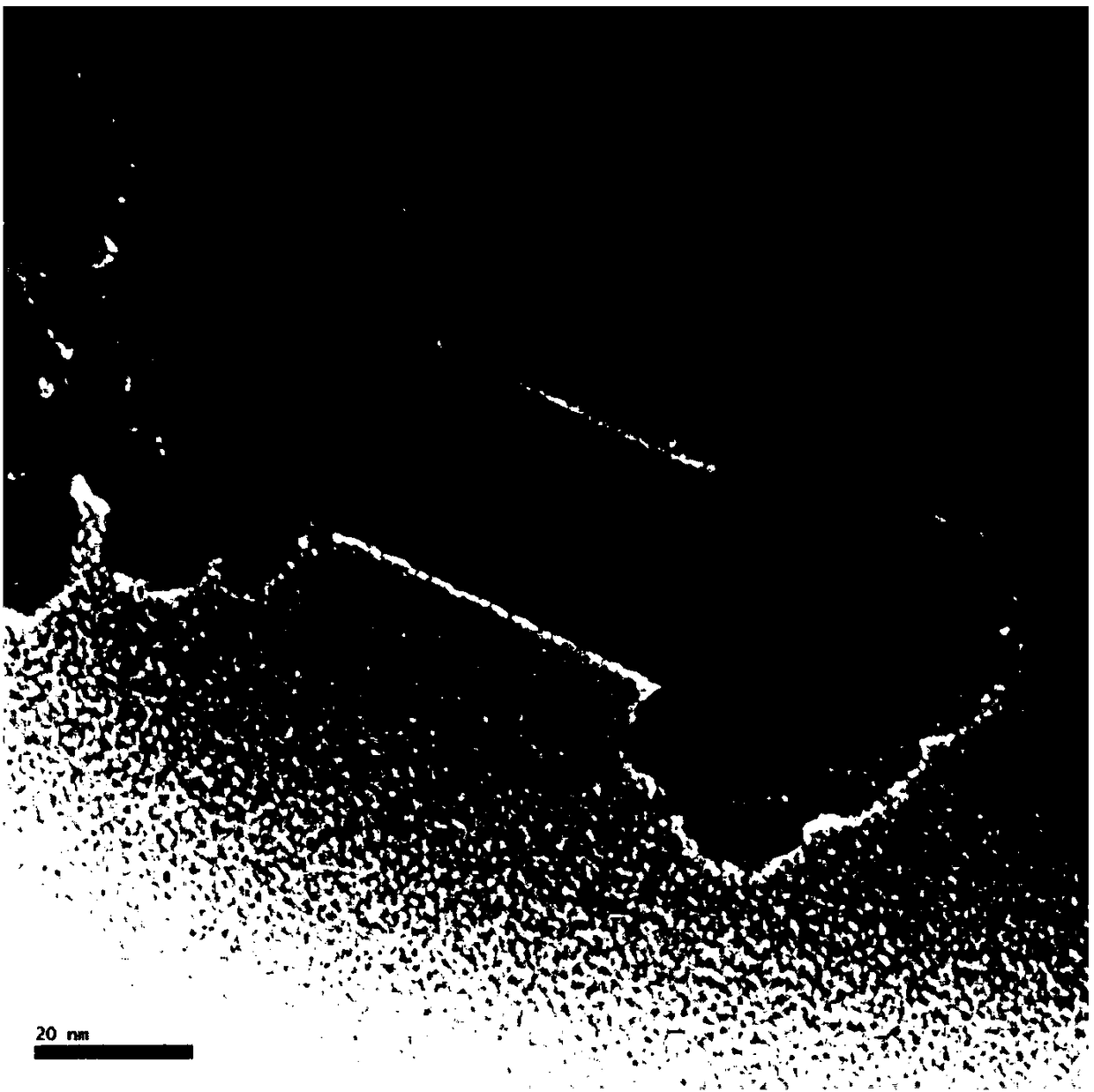

[0030] The method for preparing the Au nanorod seed solution was as follows: in a glass bottle with a capacity of 20 mL, 5 mL of 0.5 mM chloroauric acid was mixed with 5 mL of 0.2 M cetyltrimethylammonium bromide solution, and then injected with 0.6 mL of fresh For the prepared 0.01M sodium borohydride solution, stop stirring after 2 minutes, and let it stand at room temperature for 30 minutes before use. The preparation method of the growth solution is as follows. Dissolve 7.0g of cetyltrimethylammonium bromide and 1.234g of sodium oleate in 250mL of warm water at 50°C in a conical flask with a capacity of 1L, and wait for the solution to cool to 30°C , add 18mL 4mM silver nitrate solution, keep 15min; then add 250mL 1mM chloroauric acid solution, stir for 90min, add 3mL hydrochloric acid (12.1M) to adjust the pH value; after slow stirring for 15min, add 1.25mL0.064M ascorbic acid solution, stir vigorously After 30 s, inject 0.8 mL of the seed solution into the growth solutio...

Embodiment 2

[0034] The method for preparing the Au nanorod seed solution was as follows: in a glass bottle with a capacity of 20 mL, 5 mL of 0.5 mM chloroauric acid was mixed with 5 mL of 0.2 M cetyltrimethylammonium bromide solution, and then injected with 0.6 mL of fresh For the prepared 0.01M sodium borohydride solution, stop stirring after 2 minutes, and let it stand at room temperature for 60 minutes before use. The preparation method of the growth solution is as follows. Dissolve 7.0g of cetyltrimethylammonium bromide and 1.234g of sodium oleate in 250mL of warm water at 50°C in a conical flask with a capacity of 1L, and wait for the solution to cool to 30°C , add 24mL 4mM silver nitrate solution, keep 15min; then add 250mL 1mM chloroauric acid solution, stir for 90min, add 5mL hydrochloric acid (12.1M) to adjust the pH value; after slow stirring for 15min, add 1.25mL0.064M ascorbic acid solution, stir vigorously After 30 s, inject 0.5 mL of the seed solution into the growth solutio...

Embodiment 3

[0038] The method for preparing the Au nanorod seed solution was as follows: in a glass bottle with a capacity of 20 mL, 5 mL of 0.5 mM chloroauric acid was mixed with 5 mL of 0.2 M cetyltrimethylammonium bromide solution, and then injected with 0.6 mL of fresh For the prepared 0.01M sodium borohydride solution, stop stirring after 2 minutes, and let it stand at room temperature for 45 minutes before use. The preparation method of the growth solution is as follows. Dissolve 7.0g of cetyltrimethylammonium bromide and 1.234g of sodium oleate in 250mL of warm water at 50°C in a conical flask with a capacity of 1L, and wait for the solution to cool to 30°C , add 36mL 4mM silver nitrate solution, keep 15min; then add 250mL 1mM chloroauric acid solution, stir for 90min, add 2mL hydrochloric acid (12.1M) to adjust the pH value; after slow stirring for 15min, add 1.25mL0.064M ascorbic acid solution, stir vigorously After 30 s, inject 0.3 mL of the seed solution into the growth solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com