Deep treatment method of high-salt organic sewage

A technology of organic sewage and advanced treatment, applied in water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. The effect of improving the current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

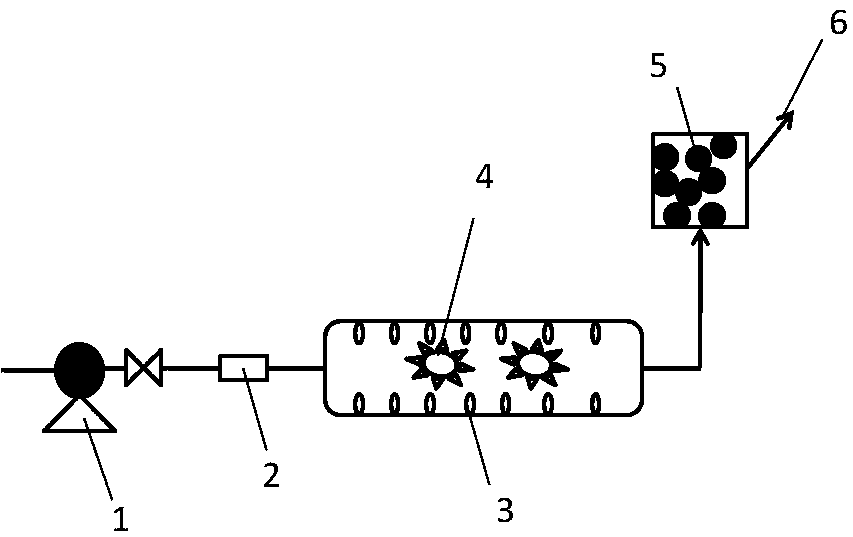

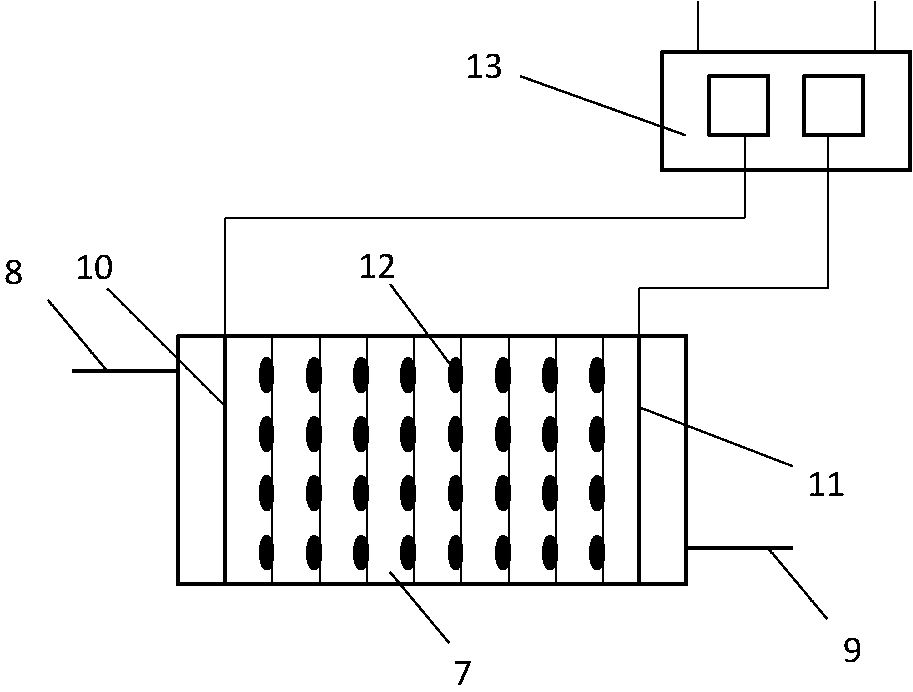

[0030] A method for advanced treatment of high-salt organic sewage, the method comprising the following steps:

[0031] Step 1. Pretreatment: sort the high-salt organic sewage through the coarse mechanical grid, and then crush the impurities through the fine mechanical grid, and then enter the cyclone grit chamber for treatment;

[0032] Step 2. Electrocoagulation precipitation: adjust the pH of the effluent from the cyclone grit chamber to 3.0 and then enter the electrocoagulation tank. Aluminum is used as the anode and stainless steel is used as the cathode. Pulse current electrolysis is used, and the electrode change cycle is 600s. The electrolyzed aluminum ions form colloids It can absorb suspended particles, colloids, and organic matter in sewage, and OH produced by hydrogen evolution at the cathode - Combine with heavy metal ions to form precipitates;

[0033] Step 3, UV-ozone-ultrasonic combined reaction section: pass the effluent from the electrocoagulation tank into ...

Embodiment 2

[0038] A method for advanced treatment of high-salt organic sewage, the method comprising the following steps:

[0039] Step 1. Pretreatment: sort the high-salt organic sewage through the coarse mechanical grid, and then crush the impurities through the fine mechanical grid, and then enter the cyclone grit chamber for treatment;

[0040] Step 2. Electrocoagulation precipitation: Adjust the pH of the effluent from the cyclone grit chamber to 3.5 and then enter the electrocoagulation tank. Aluminum is used as the anode and stainless steel is used as the cathode. Pulse current electrolysis is used, and the electrode change cycle is 700s. The electrolyzed aluminum ions form colloids It can absorb suspended particles, colloids, and organic matter in sewage, and OH produced by hydrogen evolution at the cathode - Combine with heavy metal ions to form precipitates;

[0041] Step 3, UV-ozone-ultrasonic combined reaction section: pass the effluent from the electrocoagulation tank into ...

Embodiment 3

[0046] A method for advanced treatment of high-salt organic sewage, the method comprising the following steps:

[0047] Step 1. Pretreatment: sort the high-salt organic sewage through the coarse mechanical grid, and then crush the impurities through the fine mechanical grid, and then enter the cyclone grit chamber for treatment;

[0048] Step 2. Electrocoagulation precipitation: adjust the pH of the effluent from the cyclone grit chamber to 4.0 and then enter the electrocoagulation tank. Aluminum is used as the anode and stainless steel is used as the cathode. Pulse current electrolysis is used, and the electrode change cycle is 800s. The electrolyzed aluminum ions form colloids It can absorb suspended particles, colloids, and organic matter in sewage, and OH produced by hydrogen evolution at the cathode - Combine with heavy metal ions to form precipitates;

[0049] Step 3, UV-ozone-ultrasonic joint reaction section: pass the effluent from the electrocoagulation tank into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com