Self-healing hydrogel of cellulose-dopamine-polymer composite material as well as preparation method and application of self-healing hydrogel

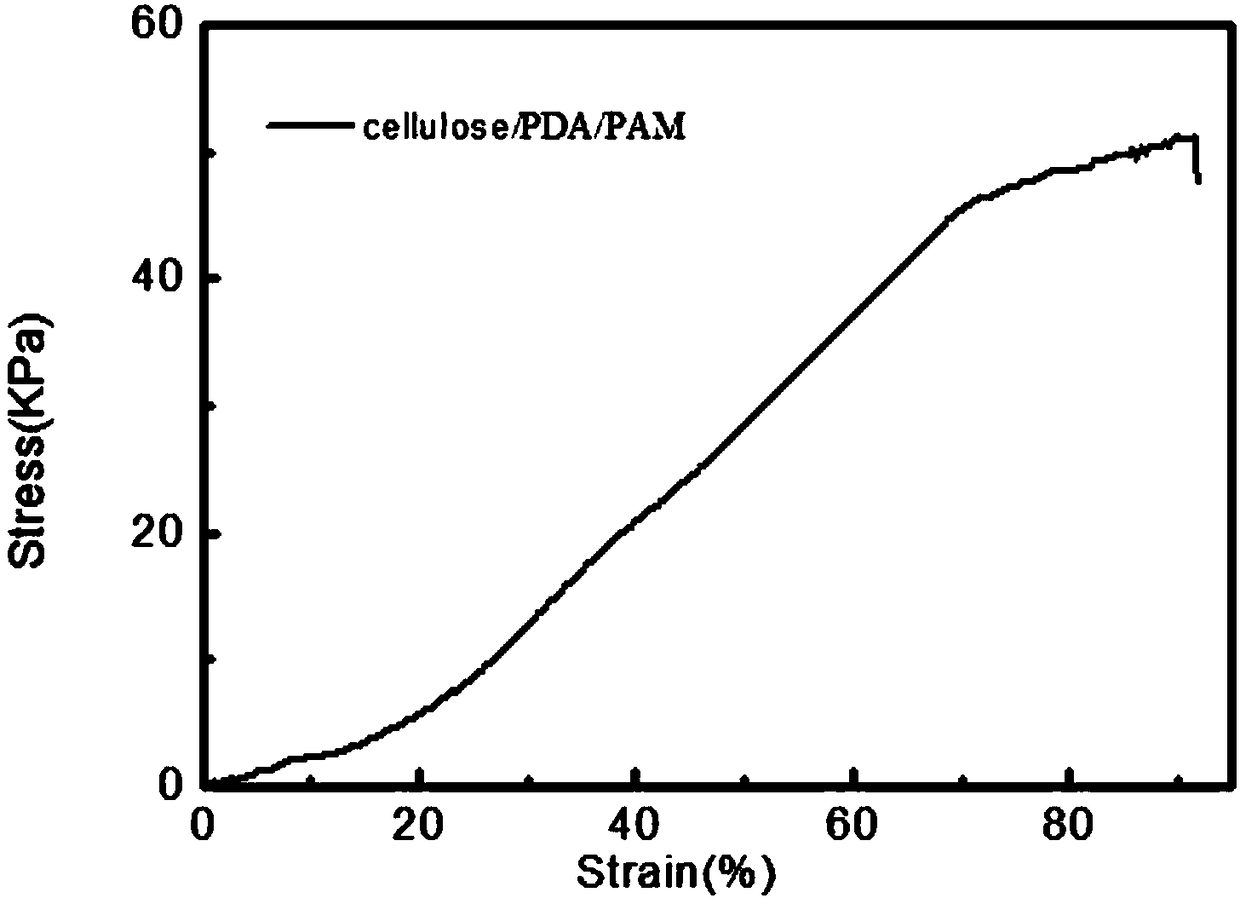

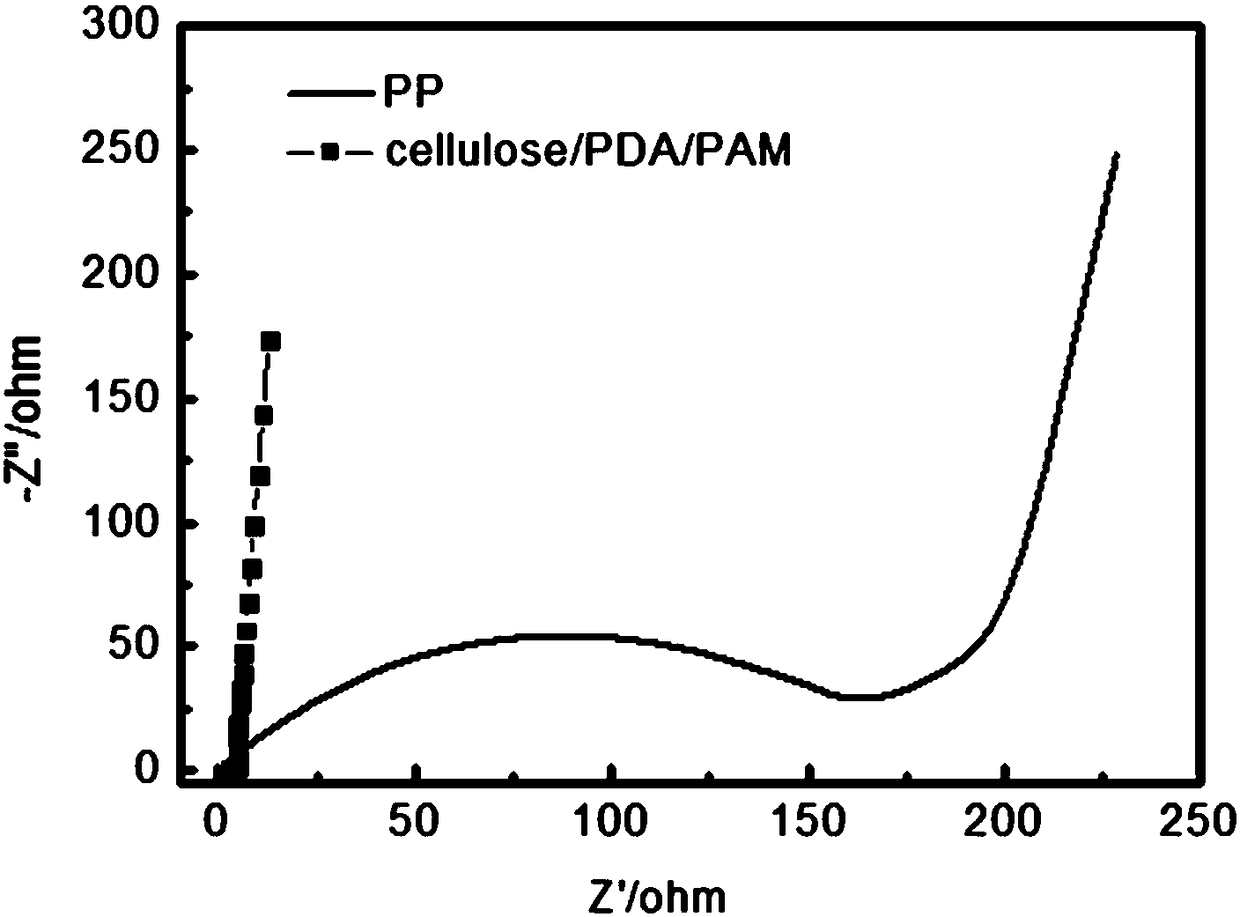

A composite material, cellulose technology, applied in conductive materials, conductive materials, organic material conductors and other directions, can solve problems such as non-recyclable, conductive materials do not have repair ability, etc., to achieve short reaction time, good electrical conductivity and mechanical properties , the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a self-healing hydrogel of cellulose-dopamine-polymer composite material, comprising the steps of:

[0044] 1) Using sodium hydroxide, urea and distilled water as raw materials, configure an alkali urea solution according to the mass ratio of 7:12:81;

[0045] 2) Mix 2 g of microcrystalline cellulose and 98 g of -10°C pretreated alkali urea solution and stir rapidly for 15 minutes to obtain the microcrystalline cellulose alkali urea solution; then freeze the microcrystalline cellulose alkali urea solution at -20°C for 12 hours , and then take it out and stir and dissolve at room temperature to obtain a more uniformly dispersed cellulose alkali urea solution;

[0046] 3) Add 1 g of epichlorohydrin to 10 g of cellulose alkali urea solution in an oil bath at 30° C., and then stir for 15 min to obtain the first mixed liquid.

[0047] 4) At room temperature, 20 mg of dopamine was added to the first mixed solution, and then stirred for 30 min to obtain...

Embodiment 2

[0052] A self-healing hydrogel for preparing cellulose-dopamine-polymer composites, the method is the same as in Example 1, except that:

[0053] Step 2) Mix 3 g of corncob cellulose and 97 g of -12°C pretreated alkali urea solution and stir rapidly for 15 minutes to obtain Avicel alkali urea solution; then place the Avicel alkali urea solution at -20°C and freeze 12h, then take it out and stir and dissolve at room temperature to obtain a more uniformly dispersed microcrystalline cellulose alkali urea solution;

[0054] The reaction time in step 3) is 10min.

Embodiment 3

[0056] A self-healing hydrogel for preparing cellulose-dopamine-polymer composites, the method is the same as in Example 1, except that:

[0057] Step 4) Add 30 mg of dopamine into the first mixed solution at room temperature, and then stir to obtain the second mixed solution;

[0058] The reaction time in step 3) is 20min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com