Method for preparing ordered porous TC4 alloy

A technology of alloys and alloy powders, applied in the field of ordered porous titanium alloys, can solve the problems of disconnected pores, disordered pores, small pores, etc., and achieve the effects of ensuring excellent performance, shortening the production process, and optimizing pore morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Material name: ordered porous TC4 alloy

[0021] Material specifications: 60mm×Φ150mm cylindrical ordered porous TC4 alloy

[0022] Chemical composition (mass percentage): Ti element mass percentage is 90%, Al element mass percentage is 6% and V element mass percentage is 4%.

[0023] Experimental equipment: planetary high-energy ball mill, vacuum hot-press sintering furnace.

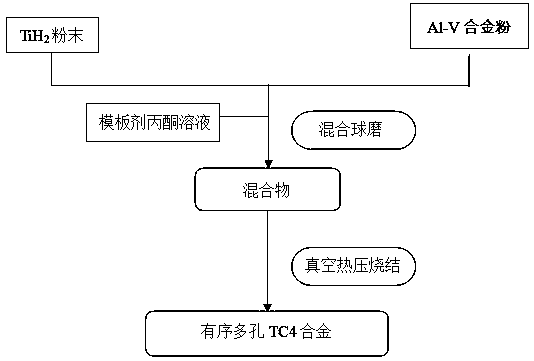

[0024] Such as figure 1 As shown, the specific preparation process steps:

[0025] (1) Raw material preparation: according to the standard composition ratio of Ti-6Al-4V alloy, weigh 325 mesh TiH 2 powder, Al-V alloy powder, TiH 2 Both the powder and the Al-V alloy powder are commercially available, the same below, and mixed to obtain a mixed powder;

[0026] (2) Add a templating agent acetone solution of 5% of the mass of the mixed powder to the mixed powder in step (1) to obtain a mixture, wherein the templating agent is BHPA (2,2-dimethylolpropionic acid), and the templating agent acetone...

Embodiment 2

[0031] Material name: ordered porous TC4 alloy

[0032] Material specifications: 60mm×Φ150mm cylindrical ordered porous TC4 alloy

[0033] Chemical composition (mass percentage): Ti element mass percentage is 90%, Al element mass percentage is 6% and V element mass percentage is 4%.

[0034] Experimental equipment: planetary high-energy ball mill, vacuum hot-press sintering furnace.

[0035] Concrete preparation process steps:

[0036] (1) Raw material preparation: according to the standard composition ratio of Ti-6Al-4V alloy, weigh 400 meshes of TiH 2 powder, Al-V alloy powder, and mixed to obtain mixed powder;

[0037] (2) Add a templating agent acetone solution of 10% of the mass of the mixed powder to the mixed powder in step (1) to obtain a mixture, wherein the templating agent is BHPA (2,2-dimethylolpropionic acid), and the templating agent acetone solution is A mixture obtained by dissolving BHPA (2,2-dimethylolpropionic acid) in acetone at a mass ratio of 1:7;

...

Embodiment 3

[0042] Material name: ordered porous TC4 alloy

[0043] Material specifications: 60mm×Φ150mm cylindrical ordered porous TC4 alloy

[0044] Chemical composition (mass percentage): Ti element mass percentage is 90%, Al element mass percentage is 6% and V element mass percentage is 4%.

[0045] Experimental equipment: planetary high-energy ball mill, vacuum hot-press sintering furnace.

[0046] Such as figure 1 As shown, the specific preparation process steps:

[0047] (1) Raw material preparation: according to the standard composition ratio of Ti-6Al-4V alloy, weigh 400 meshes of TiH 2 powder, Al-V alloy powder, and mixed to obtain mixed powder;

[0048] (2) Add a templating agent acetone solution of 15% of the mass of the mixed powder to the mixed powder in step (1) to obtain a mixture, wherein the templating agent is BHPA (2,2-dimethylolpropionic acid), and the templating agent acetone solution is A mixture obtained by dissolving BHPA (2,2-dimethylolpropionic acid) in ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com