Single end-pumped high-power narrow-pulse fundamental mode laser and working method thereof

A working method and high-power technology, applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as reducing peak power frequency doubling, triple frequency conversion efficiency, increasing component surface film damage, and reducing laser service life. Achieve the effects of improving nonlinear conversion efficiency, avoiding complex structural problems, and suppressing the generation of multi-mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

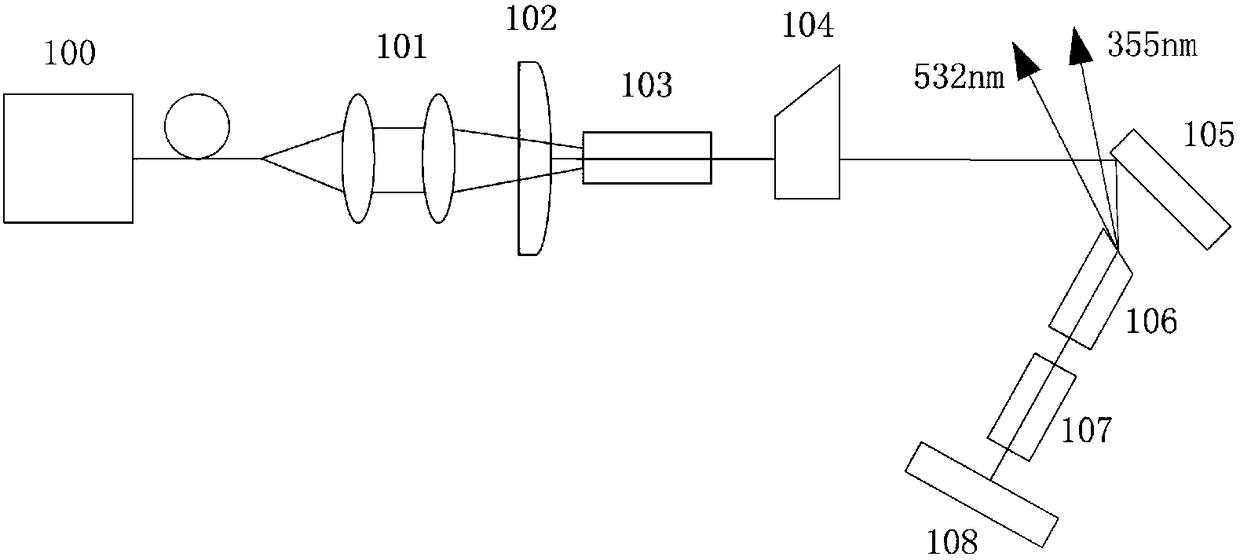

[0037] Such as figure 1 shown.

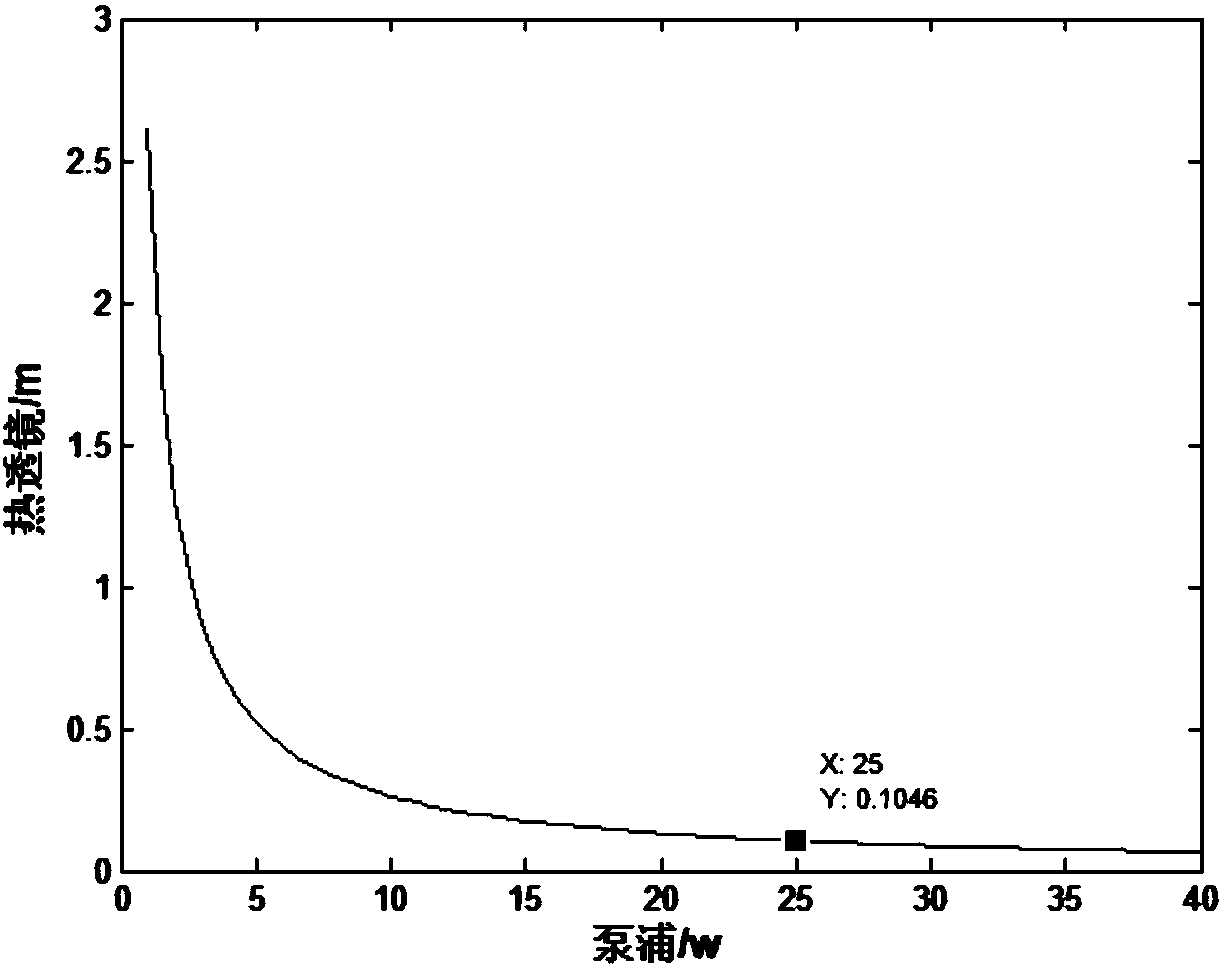

[0038] In this embodiment, the pumping power of the LD is 30W, the center wavelength is 808nm, the half-wave width is 2nm, the core diameter of the pigtail is 400um, and the numerical aperture is NA=0.22. Laser crystal 103 is Nd:YVO 4 Crystal, coated with 808nm anti-reflection coating and 1064nm anti-reflection coating on both surfaces, the crystal size is 3×3×12mm 3 , the doping concentration is 0.3%. The temperature of the crystal was controlled by TEC, and the temperature was controlled at 30°C. The radius of curvature of the plano-convex lens 102 is 200mm, and the surface is coated with a 1064nm high reflection and 808nm anti-reflection coating. The surface of the first flat mirror 105 is coated with 1064nm high-reflection film and 532nm high-reflection film. The frequency doubling crystal 107 is a type I phase matching LBO crystal, and the frequency tripler crystal 106 is a type II phase matching LBO crystal. The temperature of the f...

Embodiment 2

[0049] A working method of the fundamental mode laser as described in embodiment 1, comprising steps as follows:

[0050] 1) The pumping source 101 generates pumping light; the coupling lens group 101 couples the pump spot into the laser crystal 103, and single-end pumps the laser crystal 103 to generate fundamental frequency light; the coupling lens group 101 has a certain amplification ratio for the output spot of LD fiber;

[0051] 2) The fundamental frequency light oscillates in the resonant cavity; the fundamental frequency light passes through the frequency doubling crystal 107 twice for frequency doubling conversion to obtain frequency doubling light; the frequency doubling light is combined with the base frequency The frequency tripled light passes through the frequency tripled crystal 106 for sum frequency at the same time, and the generated tripled frequency light is output from the end of the frequency tripled crystal 106 provided with the Brewster's angle.

[0052...

Embodiment 3

[0057] As the working method of the fundamental mode laser described in embodiment 2, further, in the step 2), it also includes the step of adjusting the angles of the second flat mirror 108, the triple frequency crystal 106 and the frequency double crystal 107; by adjusting the first The angle of the second flat mirror 108 is used to obtain frequency doubled light; by adjusting the angles of the triple frequency crystal 106 and the frequency doubled crystal 107, the output light power next to the first flat mirror 105 is maximized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com