Nitrogen-oxides-containing exhaust gas comprehensive utilization method

A nitrogen oxide and tail gas technology, applied in chemical instruments and methods, separation methods, preparation of alkali metal nitrates, etc., can solve the problems of less sodium saltpeter, limited profit margins, and high energy consumption, and achieves wide popularization and application value, operation Convenience and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

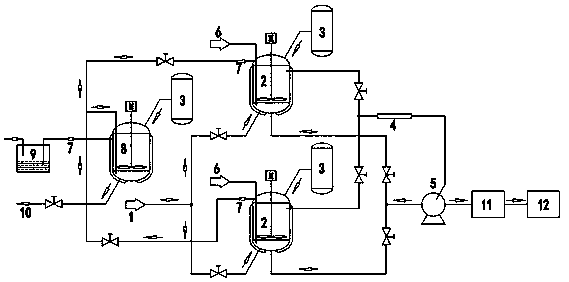

[0029] Such as figure 1 As shown, the oxidized nitrogen oxide gas enters the conversion absorption tower through the air inlet for cyclic absorption. The absorption tower adds nearly 200L of water as the absorption liquid in advance, and adds solid potassium chloride (content 95%) from the feed inlet under constant stirring. 150kg, heat and stir at 70°C and continue to feed nitrogen oxide gas for 160 minutes. When the potassium chloride in the suspension dissolves slowly or no longer dissolves, turn on the air compressor while it is hot and aerate through the aeration port to drive away the metathesis The hydrogen chloride gas generated by the reaction, the mixture containing hydrogen chloride and nitrogen oxides is passed into the redox absorption tower with the waste diamond cutter head in advance to absorb; stop aeration after 50 minutes, and the aeration is completed. - The mass concentration is controlled at 140g / L; continue to feed nitrogen oxide tail gas and continue he...

Embodiment 2

[0032] Such as figure 1 As shown, the oxidized nitrogen oxide gas enters the conversion absorption tower through the air inlet for cyclic absorption. The absorption tower adds nearly 400L of water as the absorption liquid in advance, and adds solid potassium chloride (content 95%) from the feed inlet under constant stirring. 300kg, heat and stir at 70°C and continue to feed nitrogen oxide gas for 240min. When the potassium chloride in the suspension dissolves slowly or no longer dissolves, turn on the air compressor while it is hot and aerate through the aeration port to drive away The hydrogen chloride gas generated by the metathesis reaction, the mixture containing hydrogen chloride and nitrogen oxides is passed into the redox absorption tower with the waste diamond cutter head in advance for absorption; after 60 minutes, the aeration is stopped, and the aeration is completed. - The mass concentration is controlled at 160g / L; continue to feed nitrogen oxide tail gas and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com