Preparation method of self-absorption nitrogen-sulfur doped porous carbon

A nitrogen-sulfur co-doping, porous carbon technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, nitrogen fertilizers, etc., can solve the problems of high cost, unfavorable large-scale application, complex process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

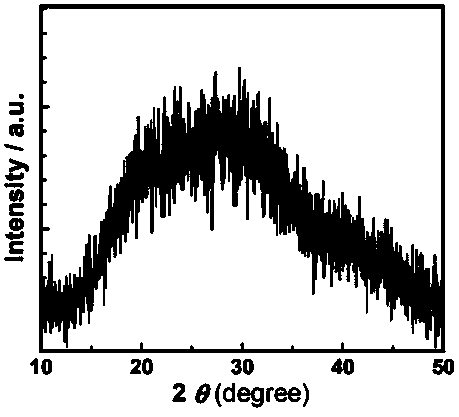

Embodiment 1

[0037]Weigh thiourea and melamine at a mass ratio of 1:1, add them to 100ml of boiled cold water, stir until completely dissolved, and then add appropriate amount of ammonium phosphate, potassium nitrate, ammonium sulfate, nitric acid to the above solution Ammonium and ferrous sulfate, the above substances are subjected to sufficient ultrasonic treatment to obtain a culture medium; put onions of appropriate size into the above culture medium for cultivation and growth, and after 1 week, the grown onions are taken out from the culture medium to obtain Samples to be processed: Cut the above samples to be processed, take the buds that grow out of them, cut them into pieces, and then dehydrate them in an oven at 100°C. After dehydration, grind the dried leaves with a mortar , and then place the product in a magnetic boat and carbonize at 500°C for 2 hours. After the carbonization is completed, water vapor is introduced into the tube furnace, and the temperature is raised to 800°C a...

Embodiment 2

[0039] Weigh thiourea and melamine at a mass ratio of 1:1, add them to 100ml of boiled cold water, stir until completely dissolved, and then add appropriate amount of ammonium phosphate, potassium nitrate, ammonium sulfate, nitric acid to the above solution Ammonium and ferrous sulfate, the above-mentioned substances are subjected to sufficient ultrasonic treatment to obtain a culture solution; put onions of appropriate size into the above-mentioned culture solution for cultivation and growth, and after 2 weeks, the grown onions are taken out from the culture solution to obtain Samples to be processed: Cut the above samples to be processed, take the buds that grow out of them, cut them into pieces, and then dehydrate them in an oven at 100°C. After dehydration, grind the dried leaves with a mortar , and then place the product in a magnetic boat and carbonize at 500°C for 2 hours. After the carbonization is completed, water vapor is introduced into the tube furnace, and the temp...

Embodiment 3

[0041] Weigh thiourea and melamine at a mass ratio of 1:1, add them to 100ml of boiled cold water, stir until completely dissolved, and then add appropriate amount of ammonium phosphate, potassium nitrate, ammonium sulfate, nitric acid to the above solution Ammonium and ferrous sulfate, the above-mentioned substances are subjected to sufficient ultrasonic treatment to obtain a culture solution; put onions of appropriate size into the above-mentioned culture solution for cultivation and growth, and after 2 weeks, the grown onions are taken out from the culture solution to obtain Samples to be processed: Cut the above samples to be processed, take the buds that grow out of them, cut them into pieces, and then dehydrate them in an oven at 100°C. After dehydration, grind the dried leaves with a mortar , and then place the product in a magnetic boat and carbonize at 500°C for 2 hours. After the carbonization, water vapor is introduced into the tube furnace, and the temperature is ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com