A method for synthesizing molybdenum disulfide monolayer nanosheets by spatial confinement method

A technology of molybdenum disulfide and nanosheets, applied in the direction of molybdenum sulfide, etc., can solve the problems of complex process, high cost and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for synthesizing molybdenum disulfide single-layer nanosheets by space confinement method, comprising steps:

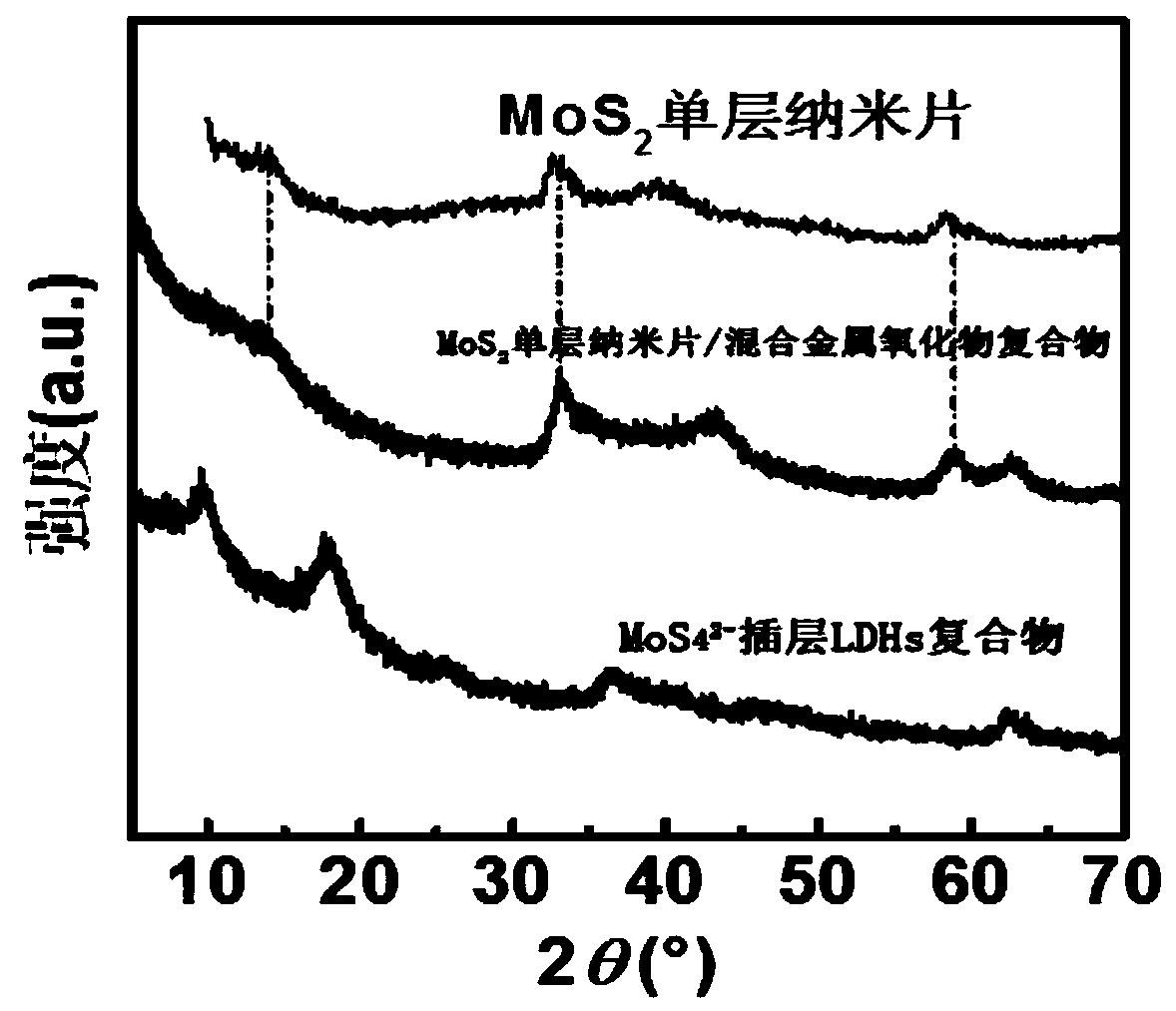

[0063] (1) Preparation of MoS by structure reconstruction method 4 2- Intercalated LDHs complex. Take 1000ml deionized water, 34g (0.1326mol) Mg(NO 3 ) 2 ·6H 2 O, 25g (0.0666mol) Al(NO 3 ) 3 9H 2 O and (1mol) 60g of urea were added to a three-necked flask, stirred at room temperature for 0.5h to dissolve the solid, and refluxed in an oil bath at 90°C for 24h. After filtration, washing, and drying at 60°C for 12 hours, CO 3 - intercalated LDHs, and then CO 3 - The intercalated LDHs were calcined in a muffle furnace at 400 °C for 2 h to obtain the metal oxide MMO. Weigh 2.0g MMO and 4.0g (NH 4 ) 2 MoS 4 Put into 10ml of degassed deionized water and stir for 24h under the protection of nitrogen. Then the dispersion was filtered, washed, and dried at 60°C for 12 hours to obtain MoS 4 2- Intercalated LDHs complex.

[0064] (2) 2gMoS 4 2- ...

Embodiment 2

[0073] A method for synthesizing molybdenum disulfide single-layer nanosheets by space confinement method, comprising steps:

[0074] (1) Preparation of MoS by ion exchange method 4 2- Intercalated LDHs complex. Take 5.1g (0.0198mol) Mg(NO 3 ) 2 ·6H 2 O and 3.8g (0.01mol) Al(NO 3 ) 3 9H 2 O was dissolved in 100ml deionized water to obtain solution A. Take 3.2g NaOH and dissolve in 100ml deionized water to obtain solution B. Under the protection of nitrogen, add solution A and solution B dropwise to 50ml of degassed deionized water at the same time under the condition of stirring, and control the final pH to 10.0, stir at room temperature for 30min; then place it in an oven at 80°C for 12h under the protection of nitrogen . After filtration, washing, and vacuum drying at 60°C for 12 hours, NO 3 - Intercalated LDHs. Weigh 1.0 g of prepared LDHs and 1.0 g (NH 4 ) 2 MoS 4 Add 10 ml of degassed deionized water, N 2 Under protection, stir at 40°C for 24h. MoS was o...

Embodiment 3

[0079] A method for synthesizing molybdenum disulfide single-layer nanosheets by space confinement method, comprising steps:

[0080] (1) Preparation of MoS by co-precipitation method 4 2- Intercalated LDHs complex. Take 5.1g (0.0198mol) Mg(NO 3 ) 2 ·6H 2 O and 3.8g (0.01mol) Al(NO 3 ) 3 9H 2 O was dissolved in 100ml deionized water to obtain solution G. Take 3.2g (0.08mol) sodium hydroxide and 2.6g (0.01mol) (NH 4 ) 2 MoS 4 Dissolve in 100ml deionized water to obtain solution H. Under the protection of nitrogen, solution G and solution H were added dropwise to 50ml degassed deionized water simultaneously under stirring condition, stirred at room temperature for 30min, and the final pH was controlled to be 10.0. Then place it in an oven at 80°C for 12 hours under the protection of an inert gas, filter, wash, and vacuum dry at 60°C for 12 hours to obtain MoS 4 2- intercalated LDHs complex

[0081] (2) 5gMoS 4 2- The intercalated LDHs composite powder was placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com