Preparing method for fatty-group-modified polycarboxylate water reducer

A polycarboxylic acid and water reducing agent technology, applied in the field of building materials, can solve the problems of no air entrainment, large loss of concrete slump, and no retardation, and achieve good fluidity retention, good material adaptability, and water reduction. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

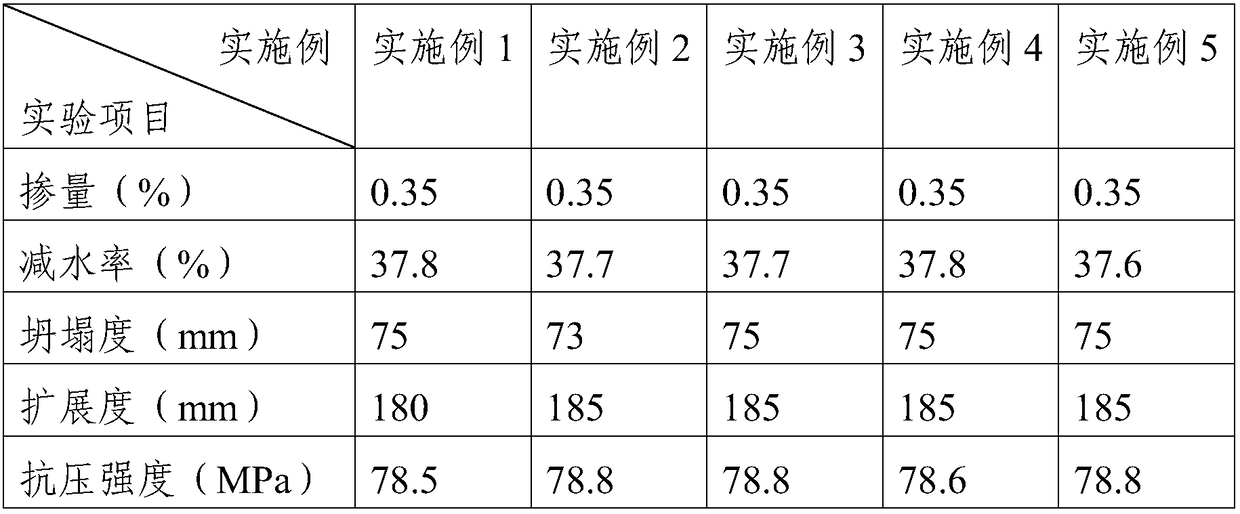

Examples

Embodiment 1

[0031] A preparation method of aliphatic modified polycarboxylate water reducer, comprising the following steps:

[0032] (1) Add 80 parts of sodium sulfite (99%), 60 parts of sodium metabisulfite (99%), and 50 parts of aqueous sodium hydroxide solution with a mass fraction of 35-38% to 400 parts of deionized water to form solution A, and heat Keep warm at 35°C;

[0033] (2) Stir 250 parts of formaldehyde, 60 parts of acetone and 70 parts of cyclohexanone to form solution B;

[0034] (3) Add solution B dropwise to solution A for 1 hour. After the dropwise addition, the final temperature is controlled at 58° C., and heat preservation reaction is carried out for 1 hour to obtain the aldehyde and ketone condensation liquid;

[0035] (4) Add 350 parts of aldehyde and ketone condensation solution, 180 parts of methallyl polyoxyethylene ether, and 3 parts of hydrogen peroxide with a concentration of 27.5% into 120 parts of deionized water to prepare solution C;

[0036] (5) Take 4...

Embodiment 2

[0041] A preparation method of aliphatic modified polycarboxylate water reducer, comprising the following steps:

[0042] (1) Add 100 parts of sodium sulfite (99%), 80 parts of sodium pyrosulfite (99%), and 55 parts of aqueous sodium hydroxide solution with a mass fraction of 35-38% into 380 parts of deionized water to form solution A, and heat Keep warm at 35°C;

[0043] (2) Stir 270 parts of formaldehyde, 50 parts of acetone, and 50 parts of cyclohexanone to form solution B;

[0044] (3) Add solution B dropwise to solution A for 1 hour. After the dropwise addition, the final temperature is controlled at 56° C., and heat preservation reaction is carried out for 1 hour to obtain the aldehyde and ketone condensation liquid;

[0045] (4) Add 400 parts of aldehyde and ketone condensation solution, 160 parts of methallyl polyoxyethylene ether, and 2.5 parts of hydrogen peroxide with a concentration of 27.5% into 120 parts of deionized water to prepare solution C;

[0046] (5) Ta...

Embodiment 3

[0051] A preparation method of aliphatic modified polycarboxylate water reducer, comprising the following steps:

[0052] (1) Add 70 parts of sodium sulfite (99%), 65 parts of sodium metabisulfite (99%), and 55 parts of aqueous sodium hydroxide solution with a mass fraction of 35-38% into 370 parts of deionized water to form solution A, and heat Keep warm at 35°C;

[0053] (2) Stir 290 parts of formaldehyde, 70 parts of acetone and 60 parts of cyclohexanone to form solution B;

[0054] (3) Add solution B dropwise to solution A for 1 hour. After the dropwise addition, the final temperature is controlled at 58° C., and heat preservation reaction is carried out for 1 hour to obtain the aldehyde and ketone condensation liquid;

[0055] (4) Add 320 parts of aldehyde and ketone condensation solution, 190 parts of methallyl polyoxyethylene ether, and 4 parts of hydrogen peroxide with a concentration of 27.5% into 125 parts of deionized water to prepare solution C;

[0056] (5) Take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com