Method for preparing fiber modified aerogel material

A technology of fiber modification and airgel, which is applied in the field of preparation of fiber modified airgel materials, can solve the problems of poor mechanical properties and medium and high temperature heat insulation performance, limit the development of airgel and energy-saving applications, and achieve improvement The effect of connection performance, avoiding sudden breakage, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of fiber modified airgel material, composition is calculated by weight, comprises the following steps:

[0029] (1) Configure 50 parts of dopamine hydrochloric acid solution and adjust the pH value to 9;

[0030] (2) add 5 parts of jute fiber mats, 1 part of alumina fiber and 2 parts of sepiolite fiber, feed nitrogen and make nitrogen in the solution reach saturation, seal;

[0031] (3) placed in a 2.5MeV, 40mA electron accelerator for irradiation stirring treatment, the irradiation dose rate is 100kGy / h, the irradiation dose is 500kGy, and the stirring speed is 100rpm;

[0032] (4) After taking it out, wash it with deionized water, and dry it at 30°C to obtain the treated mixed fiber;

[0033] (5) Get zirconium oxychloride octahydrate, titanium tetrachloride and deionized water to mix, stir and dissolve to obtain solution A, wherein, the volume ratio of zirconium oxychloride octahydrate, titanium tetrachloride and deionized water is 1:1: ...

Embodiment 2

[0043] A kind of preparation method of fiber modified airgel material, composition is calculated by weight, comprises the following steps:

[0044] (1) Configure 60 parts of dopamine hydrochloric acid solution and adjust the pH value to 9;

[0045] (2) Add 5-10 parts of jute fiber mats, 1-3 parts of alumina fibers and 2-5 parts of sepiolite fibers, feed nitrogen to make the solution saturated with nitrogen, and seal;

[0046] (3) placed in an electron accelerator of 2.5 MeV and 40 mA for irradiation stirring treatment, the irradiation dose rate is 100-200 kGy / h, the irradiation dose is 500-1000 kGy, and the stirring speed is 100-200 rpm;

[0047] (4) After taking it out, wash it with deionized water, and dry it at 35°C to obtain the treated mixed fiber;

[0048] (5) Get zirconium oxychloride octahydrate, titanium tetrachloride and deionized water to mix, stir and dissolve to obtain solution A, wherein, the volume ratio of zirconium oxychloride octahydrate, titanium tetrachlor...

Embodiment 3

[0058] A kind of preparation method of fiber modified airgel material, composition is calculated by weight, comprises the following steps:

[0059] (1) Configure 70 parts of dopamine hydrochloric acid solution and adjust the pH value to 10;

[0060] (2) Add 5-10 parts of jute fiber mats, 1-3 parts of alumina fibers and 2-5 parts of sepiolite fibers, feed nitrogen to make the solution saturated with nitrogen, and seal;

[0061](3) placed in an electron accelerator of 2.5 MeV and 40 mA for irradiation stirring treatment, the irradiation dose rate is 100-200 kGy / h, the irradiation dose is 500-1000 kGy, and the stirring speed is 100-200 rpm;

[0062] (4) After taking it out, wash it with deionized water, and dry it at 35°C to obtain the treated mixed fiber;

[0063] (5) Get zirconium oxychloride octahydrate, titanium tetrachloride and deionized water to mix, stir and dissolve to obtain solution A, wherein, the volume ratio of zirconium oxychloride octahydrate, titanium tetrachlor...

PUM

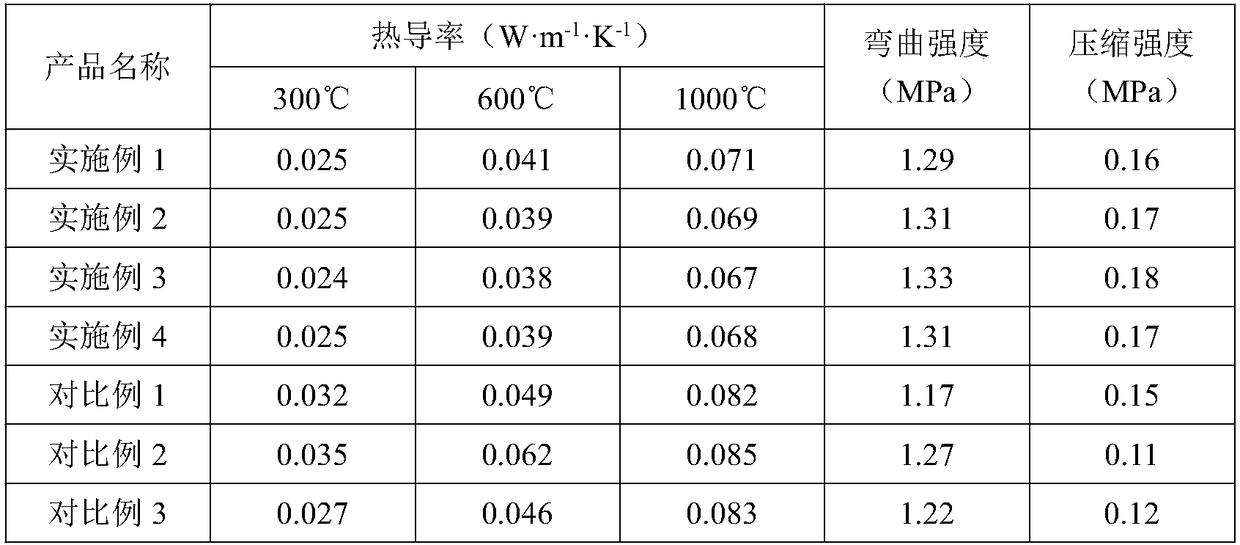

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com