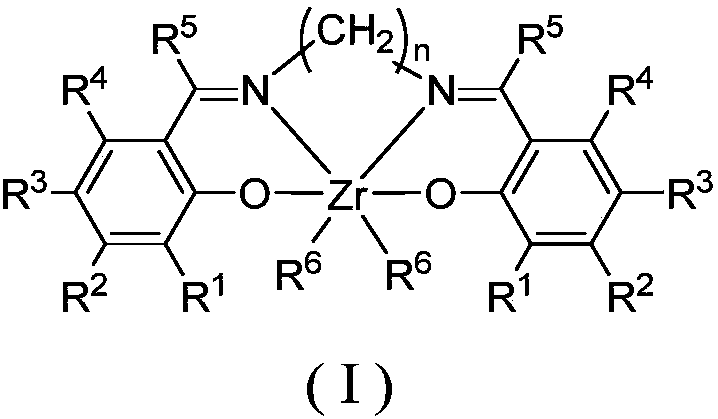

Bisphenol oxygen-imine ligand zirconium compound, as well as preparation method and application thereof

A technology of bisphenoloxyimine and zirconium compound, applied in the field of olefin polymerization, can solve the problems of limited application scope, high price, and many catalyst synthesis steps, and achieves the effects of overcoming low molecular weight, high catalytic activity and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

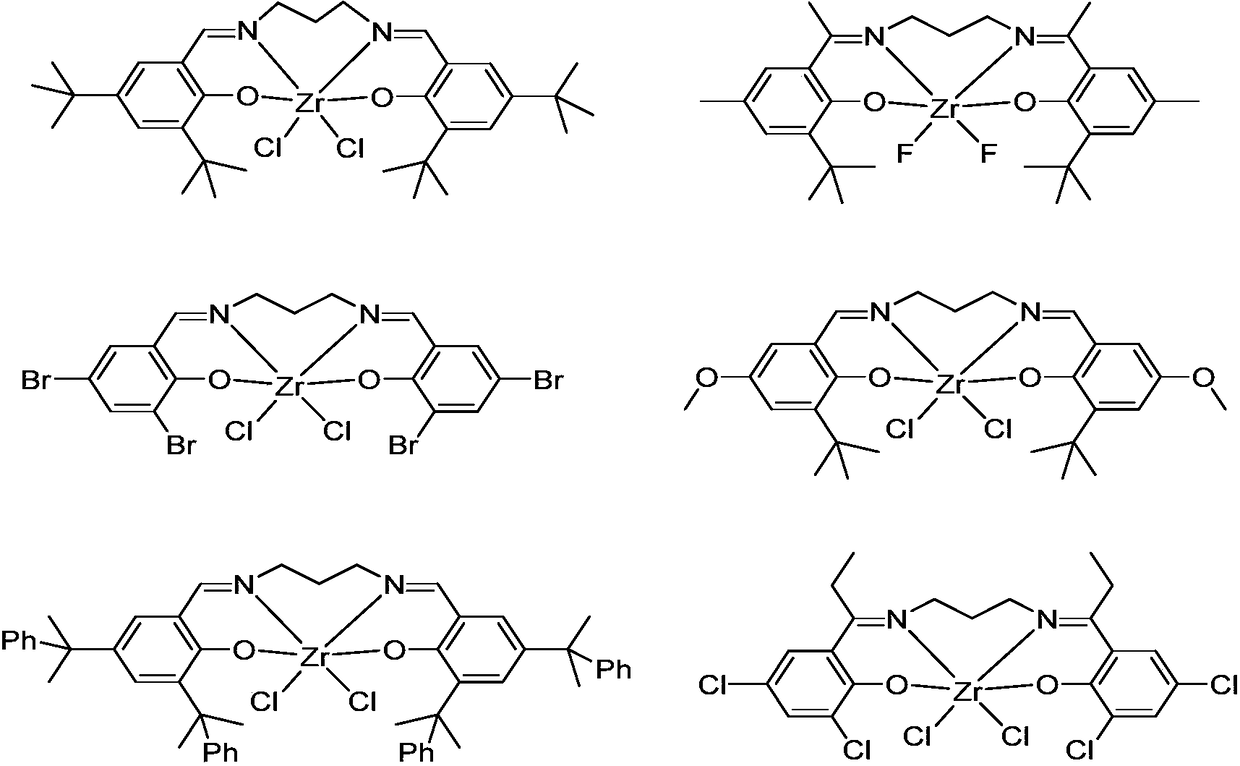

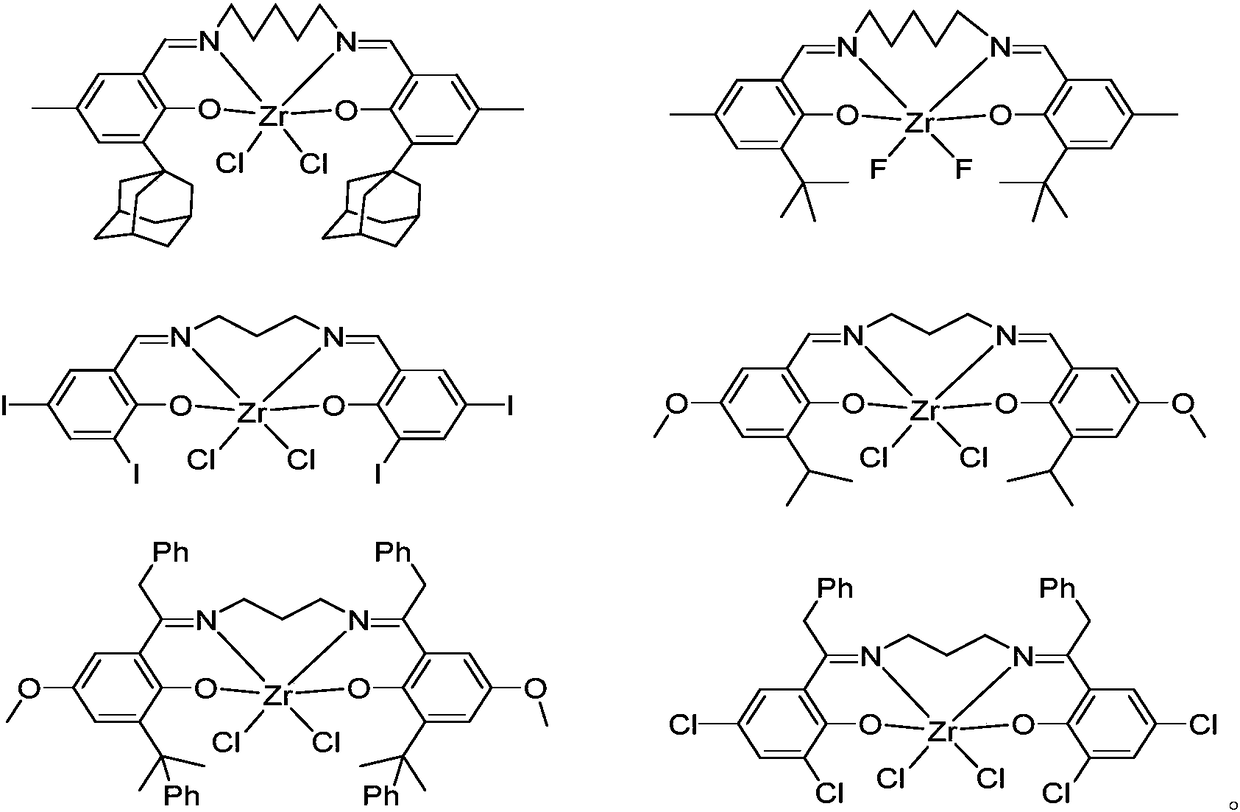

Examples

Embodiment 1

[0034] Synthesis of Ligand L1

[0035] Add 3,5-di-tert-butyl salicylaldehyde (4.68g, 20mmol), absolute ethanol (50mL) and 1.0g molecular sieves to the 100mL reaction flask successively Stir at room temperature for 5 minutes, add 1,3-propanediamine (0.74 g, 10 mmol), and react under reflux for 16 hours. The reaction liquid was filtered, and the solvent was removed from the filtrate under reduced pressure, and the product (4.11 g, yield: 81.1%) was obtained by recrystallization from petroleum ether.

[0036]

[0037] 1 H NMR (CDCl 3 ,400MHz):δ10.93(s,2H,OH),8.56(s,2H,CH=N),7.20(d,2H, 4 J=2.2Hz, ArH), 6.80(d, 2H, 4 J=2.2Hz, ArH), 3.71(t, 4H, 3 J=7.5Hz, NCH 2 ),2.01(m,2H,CH 2 CH 2 CH 2 ),1.43(s,18H,C(CH 3 ) 3 ),1.28(s,18H,C(CH 3 ) 3 ). 13 C NMR (CDCl 3 ,100MHz): δ161.4,154.3,140.4,135.4,123.2,122.7,121.5,59.4,34.5,32.2,31.6,25.0.Anal.Calcd.forC 33 h 50 N 2 o 2 : C, 78.21; H, 9.95; N, 5.53. Found: C, 78.47; H, 10.02; N, 5.77%.

Embodiment 2

[0039] Synthesis of Ligand L2

[0040] Add 3-tert-butyl-5-methyl salicylaldehyde (3.84g, 20mmol), absolute ethanol (50mL) and 1.0g molecular sieves to the 100mL reaction flask successively Stir at room temperature for 5 minutes, add 1,3-propanediamine (0.74 g, 10 mmol), and react under reflux for 16 hours. The reaction liquid was filtered, and the solvent was removed from the filtrate under reduced pressure, and the product (2.87 g, yield: 70.2%) was obtained by recrystallization from petroleum ether.

[0041]

[0042] 1 H NMR (CDCl 3 ,400MHz):δ10.79(s,2H,OH),8.44(s,2H,CH=N),7.37(d,2H, 4 J=2.4Hz, ArH), 7.08(d, 2H, 4 J=2.4Hz, ArH), 3.95(t, 4H, 3 J=7.2Hz, NCH 2 ),2.36(s,6H,ArCH 3 ),1.40(s,18H,C(CH 3 ) 3 ). 13 C NMR (CDCl 3 ,100MHz): δ161.4,157.3,140.4,135.4,123.2,122.7,121.5,61.9,34.5,31.6,21.6.Anal.Calcd.for C 26 h 36 N 2 o 2 : C, 76.43; H, 8.88; N, 6.86. Found: C, 76.47; H, 9.02; N, 6.77%.

Embodiment 3

[0044] Synthesis of Ligand L3

[0045] Add 2-hydroxy-3-cumyl-5-methoxybenzophenone (5.69g, 20mmol), absolute ethanol (50mL), 1 drop of formic acid and 1.0g molecular sieves to the 100mL reaction flask successively Stir at room temperature for 5 minutes, add 1,3-propanediamine (0.74 g, 10 mmol), and react under reflux for 16 hours. The reaction liquid was filtered, and the solvent was removed from the filtrate under reduced pressure, and the product was obtained by recrystallization from petroleum ether (3.25 g, yield: 53.6%).

[0046]

[0047] 1 H NMR (CDCl 3 ,400MHz):δ10.12(s,2H,OH),7.35-7.13(m,12H,ArH),6.85(d,2H, 4 J=2.4Hz, ArH), 3.81(s, 6H, OCH 3 ),3.67(t, 3 J=7.2Hz, 4H, NCH 2 ),2.11(m,2H,CH 2 CH 2 CH 2 ),1.81(s,6H,NCCH 3 ),1.69(s,12H,CPh(CH 3 ) 2 ). 13 CNMR (CDCl 3 for C 39 h 46 N 2 o 4 : C, 77.20; H, 7.64; N, 4.62. Found: C, 77.41; H, 7.75; N, 4.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com