SMC (sheet molding composite) Material and sidewalk system using same

A composite material and sidewalk technology, applied in applications, home appliances, other home appliances, etc., can solve the problems of uneven stress on angle steel beams, poor dimensional consistency, and increase the load of bridge decks, so as to reduce installation costs, resist compression and improve performance. High tensile strength and improved surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

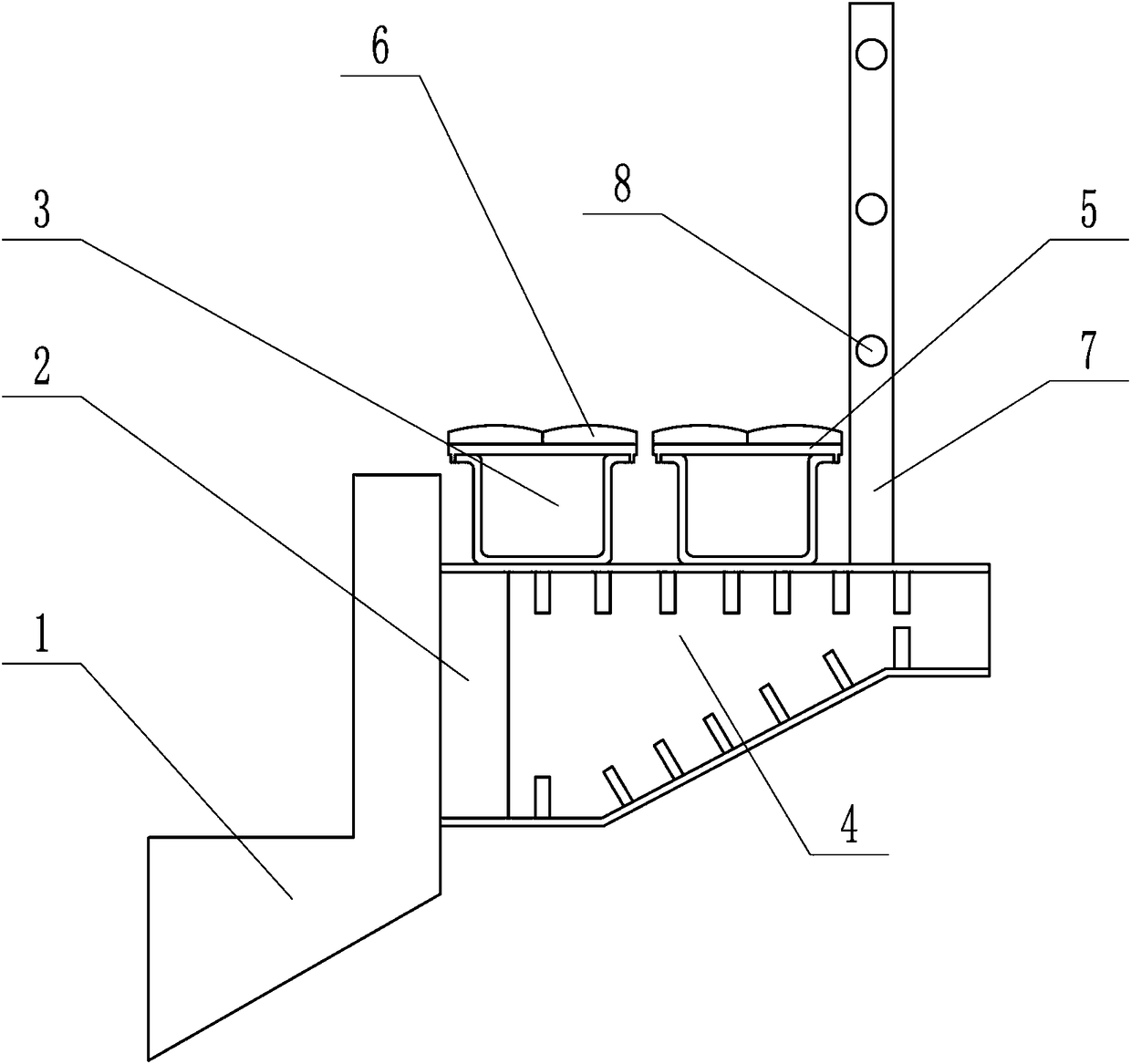

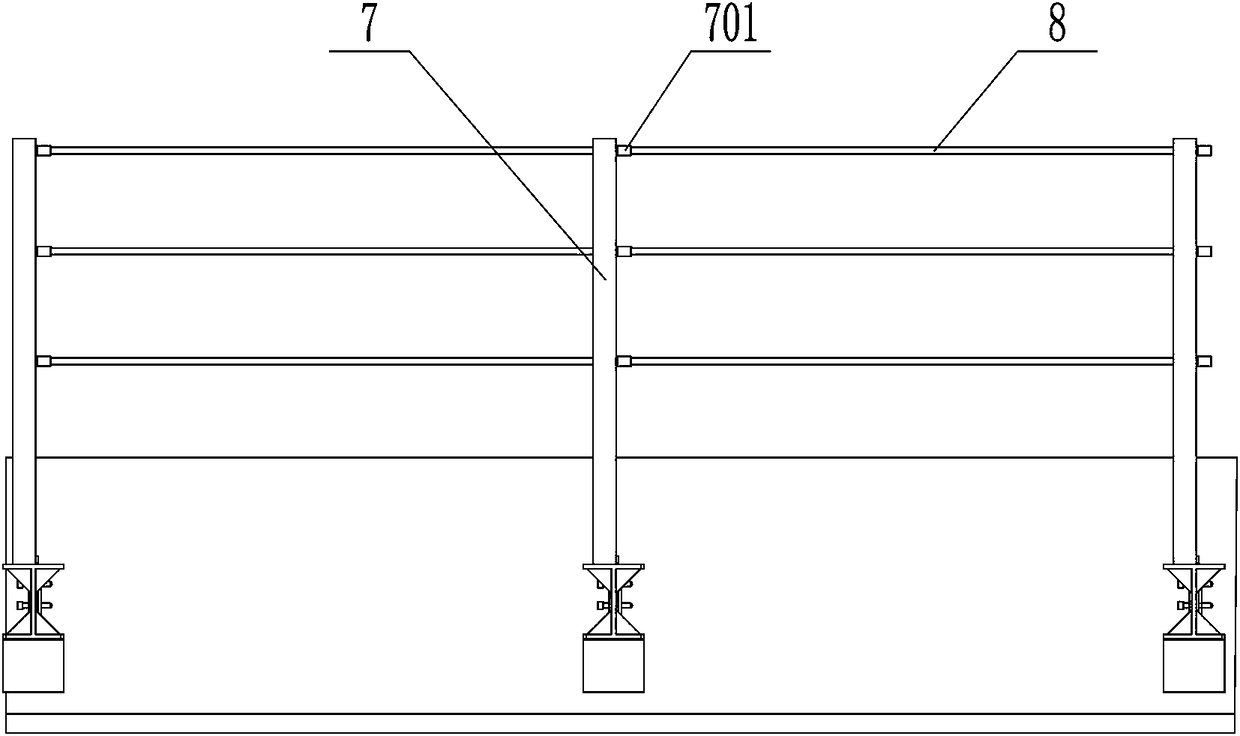

[0030] A kind of SMC composite material, it comprises the upper polyethylene film layer, upper resin paste layer, chopped glass fiber layer, continuous glass fiber layer, carbon fiber fabric layer, aramid fiber fabric layer, lower resin paste layer arranged in sequence from top to bottom layer and the lower polyethylene film layer; the upper resin paste layer is composed of the following materials in parts by weight: 65 parts of vinyl resin, 35 parts of low-shrinkage additives, 9 parts of nanocomposite preparations, 40 parts of hydrated aluminum hydroxide powder, 3 parts of thickener, 1 part of oxyacetic acid chelating titanate coupling agent and 1 part of ethylene glycol chelating titanate coupling agent. The composition ratio and preparation method of the lower resin paste layer and the upper resin paste layer are the same. The fiber directions of the chopped glass fiber layer, continuous glass fiber layer, carbon fiber fabric layer and aramid fiber fabric layer are arranged...

Embodiment 2

[0039] On the basis of Example 1, only the component distribution ratio of the resin paste layer is changed, 70 parts of vinyl resin, 30 parts of low-shrinkage additives, 11 parts of nanocomposite preparations, 30 parts of hydrated aluminum hydroxide powder, 4 parts of thickener, 1.5 parts of oxyacetic acid chelating titanate coupling agent and 0.8 parts of ethylene glycol chelating titanate coupling agent.

Embodiment 3

[0041] On the basis of Example 1, only the component distribution ratio of the resin paste layer is changed, 60 parts of vinyl resin, 40 parts of low-shrinkage additives, 8 parts of nanocomposite preparations, 50 parts of hydrated aluminum hydroxide powder, 2.5 parts of thickener, 0.8 parts of oxyacetic acid chelating titanate coupling agent and 1.5 parts of ethylene glycol chelating titanate coupling agent.

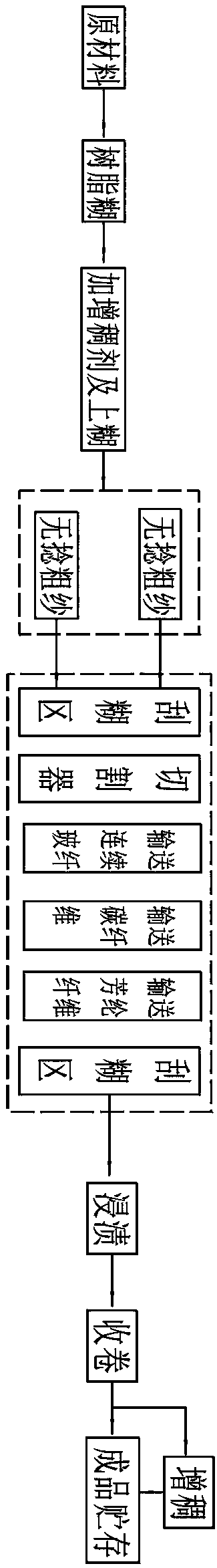

[0042] A kind of manufacture method of SMC composite material, it comprises the steps:

[0043] Step 1: In parts by weight, 60-70 parts of vinyl resin, 30-40 parts of low-shrinkage additive, 8-11 parts of nanocomposite preparation, 30-50 parts of hydrated aluminum hydroxide powder, and oxyacetic acid chelating titanate Put 0.8-1.5 parts of coupling agent, 0.8-1.5 parts of ethylene glycol chelating titanate coupling agent and 2.5-4 parts of thickener into the mixing tank, set the speed of the mixing tank to 1200 rpm, and stir for 20 minutes;

[0044] Step 2: Transfer the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com