Nano-flower array flexible air electrode material and preparation method and application thereof

A technology of air electrodes and nanoflowers, applied in the field of electrodes, can solve the problems of low conductivity limiting electrochemical performance, and achieve good cycle stability, good cycle performance, and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Carbon cloth pretreatment:

[0029] The hydrothermal reaction time is 12 to 12.5 hours.

[0030] The commercial carbon cloth was ultrasonically cleaned with acetone, ethanol and deionized water for 30 min, and dried for use.

[0031] 2) f-CoNi 2 S 4 / CP synthesis: 2mmol nickel acetate, 1mmol cobalt acetate, and 8mmol sodium sulfide were added to 60ml deionized water and stirred for 1h to form a uniform mixed solution, then the mixed solution and carbon cloth (CP) were transferred to a 100ml autoclave, Reaction at 180°C for 12h. After the hydrothermal reaction, the CP was taken out at room temperature, washed several times with ethanol and deionized water, and then dried to obtain the CoNi 2 S 4 The CP of the nanoflower array (i.e. f-CoNi 2 S 4 / CP).

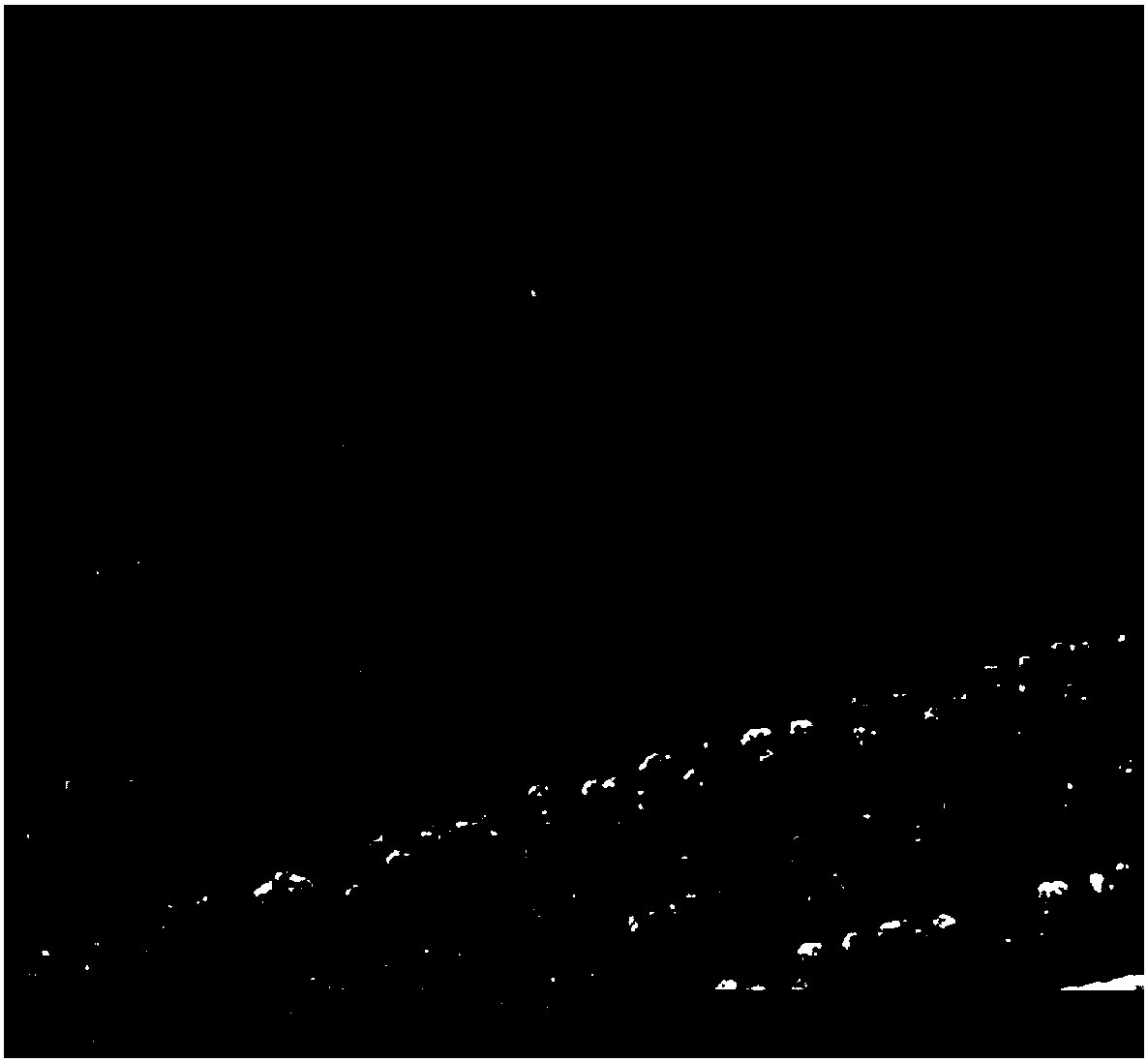

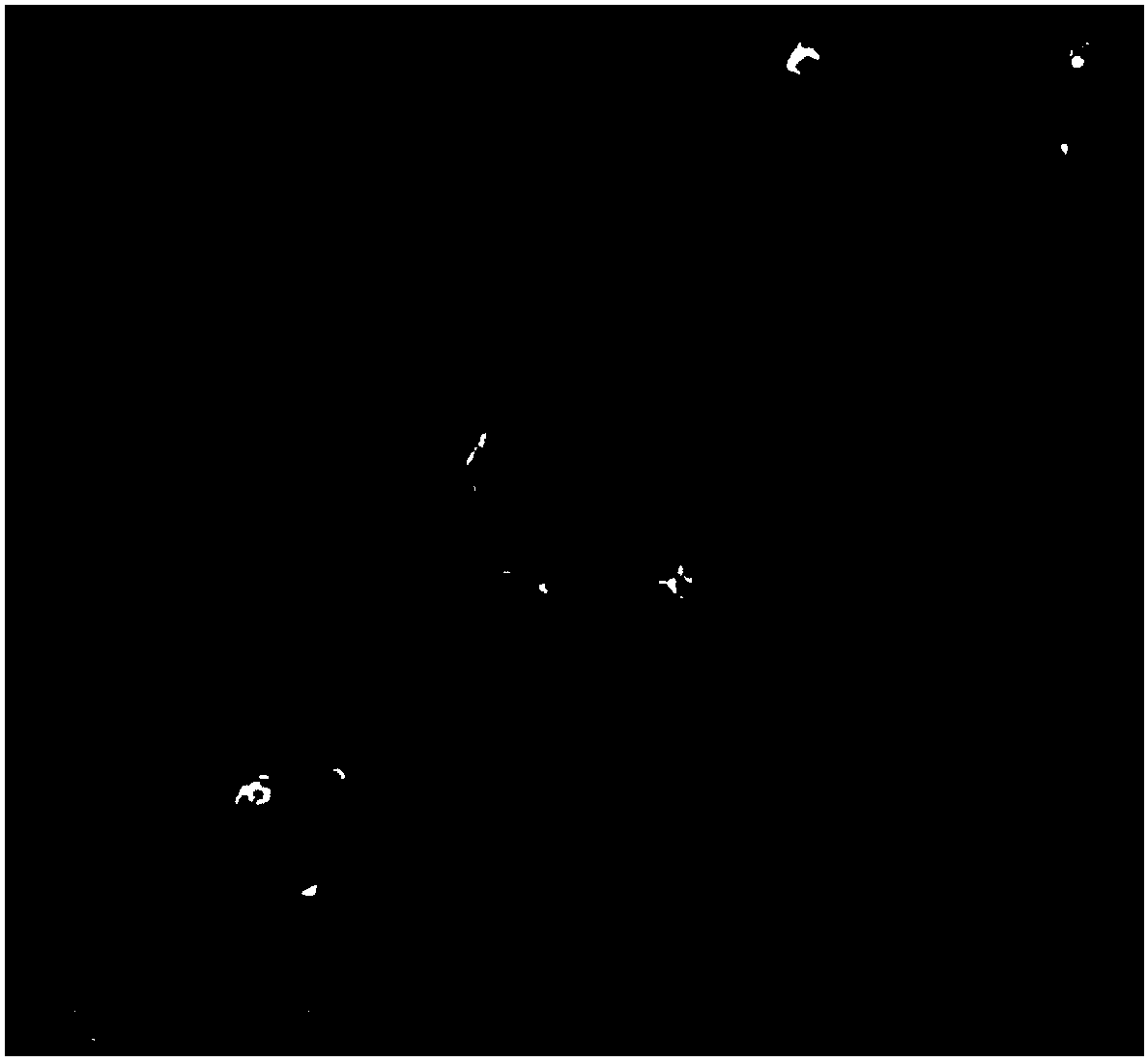

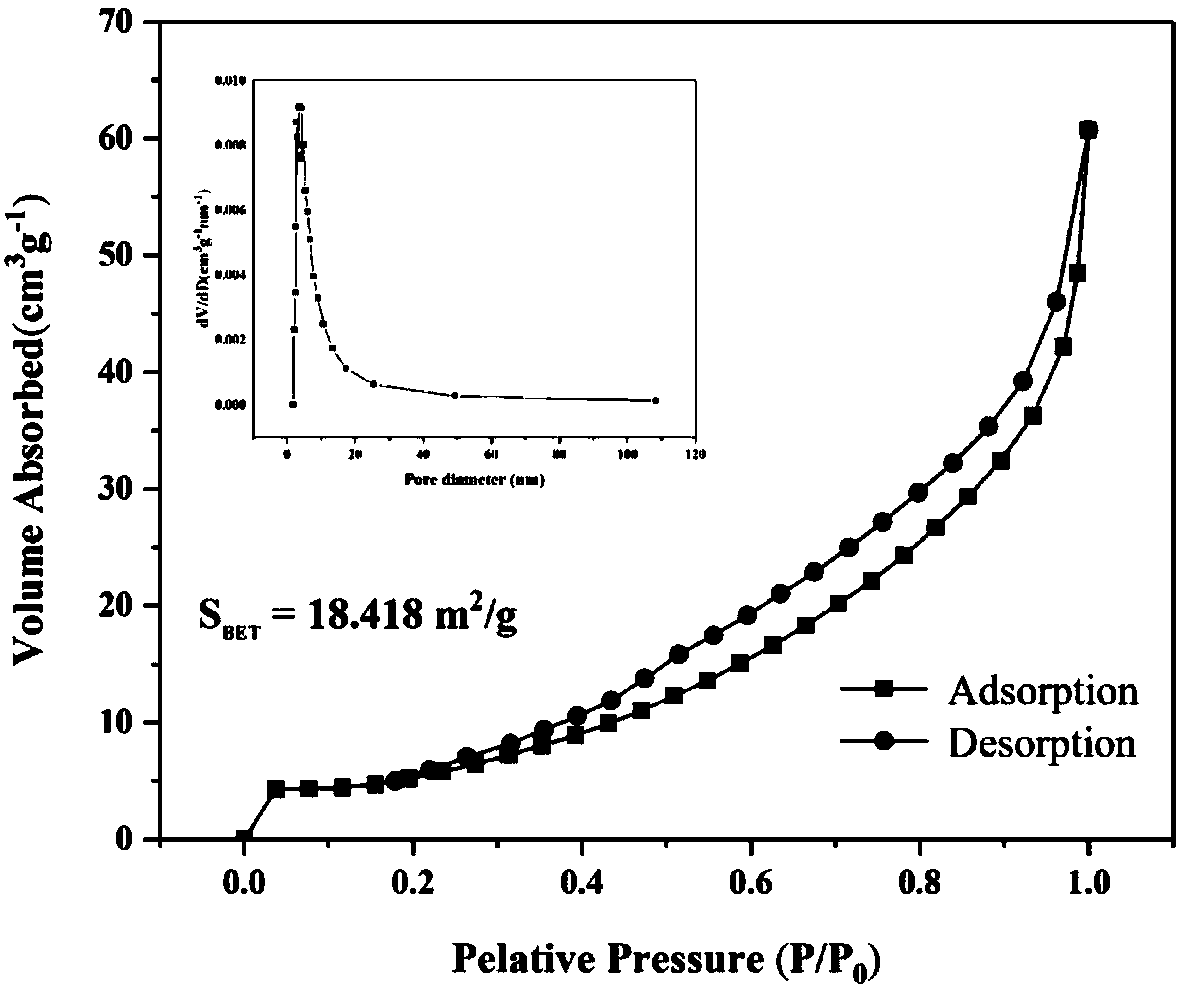

[0032] Obtain f-CoNi by embodiment 1 2 S 4 / CP looks like figure 1 , 2 as shown, image 3 for its BET graph, Figure 4 Its XRD figure. First charge and discharge performance: with f-CoNi 2 S 4 / CP catho...

Embodiment 2

[0034] 1) Carbon cloth pretreatment:

[0035] The commercial carbon cloth was ultrasonically cleaned with acetone, ethanol and deionized water for 30 min, and dried for use.

[0036] 2) f-CoNi 2 S 4 / CP synthesis: 2mmol nickel acetate, 1mmol cobalt acetate, and 8mmol sodium sulfide were added to 60ml deionized water and stirred for 1h to form a uniform mixed solution, then the mixed solution and carbon cloth (CP) were transferred to a 100ml autoclave, Reaction at 200°C for 12.5h. After the hydrothermal reaction, the CP was taken out at room temperature, washed several times with ethanol and deionized water, and then dried to obtain the CoNi 2 S 4 The CP of nanoflower arrays (i.e. f-CoNi 2 S 4 / CP).

[0037] Since the products produced in Example 1 and Example 2 of the present invention all contain carbon cloth, they can be effectively applied in other flexible and wearable power sources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com