Synthesizing method of sulfurized-chloridized isobutylene

A technology of sulfochlorination of isobutylene and synthesis method, which is applied in the preparation of hydrogenated polysulfides/polysulfides, organic chemistry, etc., and can solve the problem of increased by-products, difficulty in effectively controlling the amount of air intake, and decomposition of sulfur monochloride, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

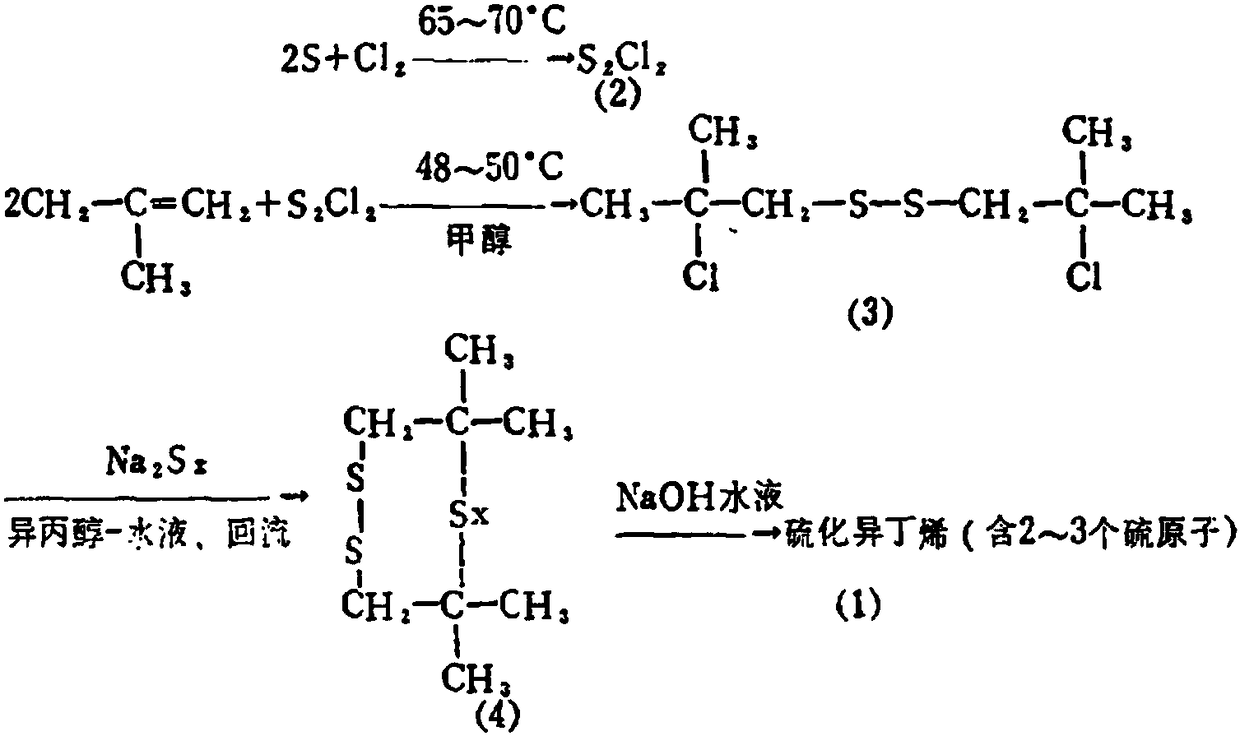

Method used

Image

Examples

Embodiment 1

[0045] A tubular reactor is adopted, the length of the reactor is 1-15m, the inner diameter is 1-6mm, and the temperature is controlled by a cooling and heating machine at 15-30°C. The outlet back pressure of the reaction system is ≥0.3MPa. Isobutene and sulfur monochloride are fed separately through the plunger pump, the feed rate is 5mL / min-3L / min, the molar ratio of isobutene to sulfur monochloride is 1.8:1~2.2:1, and the feed rate is controlled by controlling the pump. The reaction residence time is 0.5-2 hours. Crude chlorinated isobutene sulfide with a content of more than 95% is obtained.

Embodiment 2

[0047] A tubular reactor is adopted, the length of the reactor is 10-80m, the inner diameter is 2-8mm, the temperature is controlled at 20-35°C, the back pressure at the outlet of the reaction system is ≥0.5MPa, isobutylene and sulfur monochloride are respectively fed in liquid state through a plunger pump, and the The feed rate is 5mL / min-5L / min, the molar ratio of isobutene to sulfur monochloride is 1.8:1~2.2:1, and the reaction residence time is 1.0-5 hours. Crude chlorinated isobutene sulfide with a content of more than 95% is obtained.

Embodiment 3

[0049] A microchannel reactor is adopted, and the cross-sectional area of the reactor is the shortest 0.3-2 mm. In this example, the Himile Chemical umbrella microchannel reactor is used. The length of the single-chip channel is 0.5-5 m, and the liquid holding capacity is 1-500 mL. The device has a temperature control device. The temperature of the reaction system is controlled by the temperature control device to be 15-35°C. The back pressure of the reaction system outlet is ≥0.3MPa. minutes to 300mL / min, the molar ratio of isobutene to sulfur monochloride is 1.8:1 to 2.2:1, and the reaction residence time is 10 to 300 seconds. Crude chlorinated isobutene sulfide with a content of more than 95% is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com