Modified fluorosilicone isoprene rubber and preparation method thereof, bionical type aircraft tyre rubber material and preparation method thereof

A silicon isoprene rubber, rubber material technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of high instantaneous load, high inflation pressure, fast speed, etc., to broaden the scope of application, high fracture Elongation, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

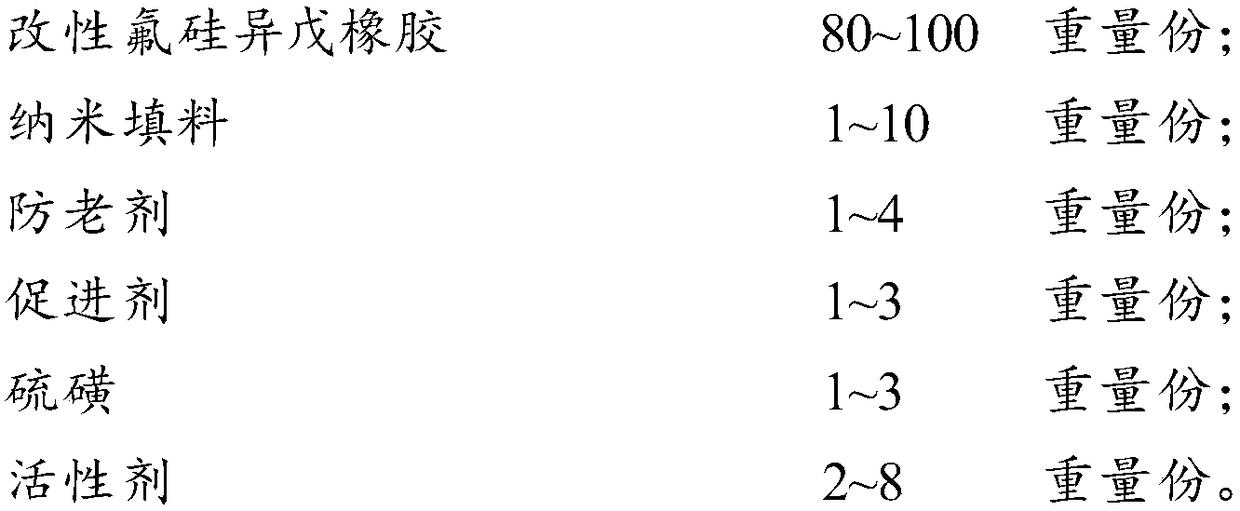

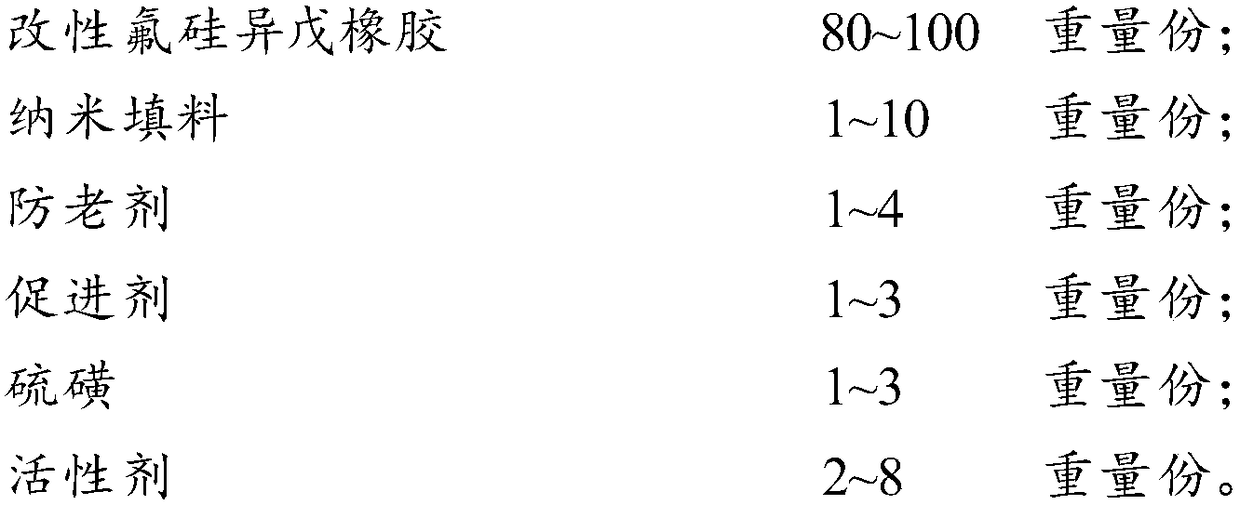

Method used

Image

Examples

preparation example Construction

[0075] The present invention also provides a preparation method of modified fluorosilicone isoprene rubber, comprising the following steps:

[0076] 1) Under the action of a metal catalyst, after reacting isoprene, an organoaluminum compound, an organoboron salt and a good solvent, a reaction system is obtained;

[0077] 2) adding fluorine-containing siloxane to the reaction system obtained in the above steps, continuing the reaction, and after stopping the reaction, post-processing to obtain fluorosilicone isoprene rubber;

[0078] 3) Epoxidizing the fluorosilicone isoprene rubber, the epoxidation reagent and the good solvent in the above steps to obtain the epoxidized fluorosilicone isoprene rubber;

[0079] 4) Treat the epoxidized fluorosilicone isoprene rubber obtained in the above steps with acid, perform condensation reaction with proteinoid, coupling agent and condensation reaction catalyst, and post-treat again to obtain modified fluorosilicone isoprene rubber.

[008...

Embodiment 1

[0147] (1) prepare fluorosilicone isoprene rubber;

[0148] Add 25μmol rare earth metal catalyst, 10ml toluene, 50μmol AlMe 3 , 5mmol isoprene, 25μmol[Ph 3 C][B(C 6 f 5 ) 4 ], after reacting at 0°C for 24h under constant stirring, add 5mmol trifluoropropylmethylcyclotrisiloxane, continue to react for 24h, add 30mL containing 5% 2,6-di-tert-butyl-4-methylphenol ethanol to stop the reaction; the reaction solution was precipitated with ethanol to precipitate solid matter, and the solid matter was vacuum-dried at 40° C., and the solvent was removed to constant weight to obtain 2.68 g of fluorosilicone isoprene rubber with a conversion rate of 100%. .

[0149] (2) preparing protein-modified fluorosilicone isoprene rubber;

[0150] Add 80 parts of the fluorosilicone isoprene rubber, m-chloroperoxybenzoic acid, and toluene in sequence in the reaction kettle, stir and react to obtain epoxidized fluorosilicone isoprene rubber, add 5 parts of spider silk-like protein, six Methyle...

Embodiment 2

[0159] (1) prepare fluorosilicone isoprene rubber;

[0160] Add 30μmol rare earth metal catalyst, 15ml toluene, 90μmol AlMe 3 , 10mmol isoprene, 50μmol[Ph 3 C][B(C 6 f 5 ) 4 ], after reacting at 25°C for 48h under constant stirring, add 2mmol trifluoropropylmethylcyclotrisiloxane, continue to react for 48h, add 35mL containing 5% 2,6-di-tert-butyl-4-methylphenol ethanol to stop the reaction; the reaction solution was precipitated with ethanol to precipitate solid matter, and the solid matter was vacuum-dried at 50° C., and the solvent was removed to constant weight to obtain 1.62 g of fluorosilicone isoprene rubber with a conversion rate of 100%. .

[0161] (2) preparing protein-modified fluorosilicone isoprene rubber;

[0162]90 parts of said fluorosilicone isoprene rubber, m-chloroperoxybenzoic acid and toluene were sequentially added into the reaction kettle, and the reaction was stirred to obtain epoxidized fluorosilicone isoprene rubber. After acid treatment, 10 par...

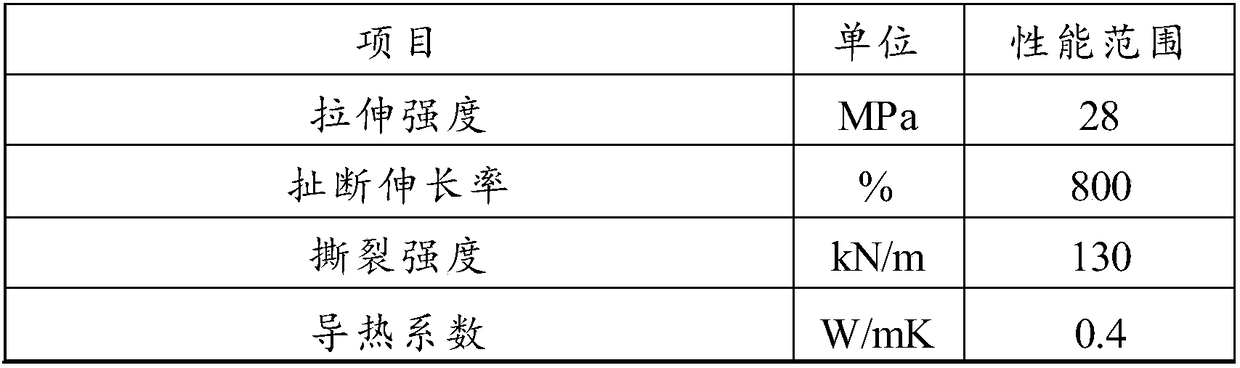

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com