Degreasing agent for glass light guide plates

A technology of glass light guide plate and degreasing agent, which is applied in the field of cleaning agent, which can solve the problems of inconspicuous degreasing effect, low operating temperature, and falling off of light guide points, and achieve the effect of efficiently removing grease, enhancing adhesion, and eliminating small air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

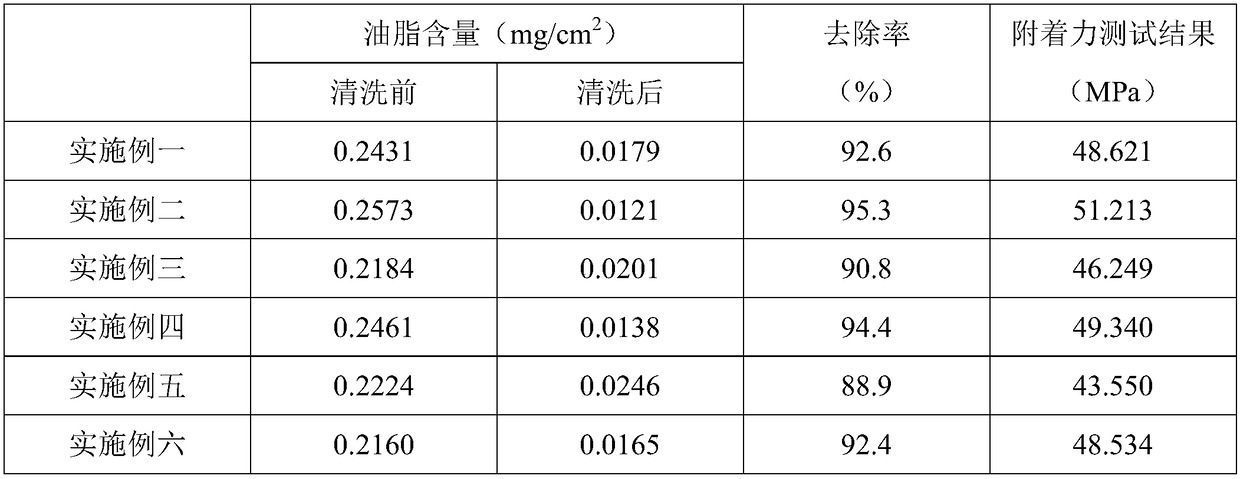

Examples

Embodiment 1

[0022] A glass light guide plate degreasing agent, comprising the following raw materials in mass fraction:

[0023] Propylene glycol methyl ether 44.79%, dimethyl succinate 50%, Pingpinga O-25 5%, polyoxyethylene polyoxypropylene stearyl ether 0.1%, polyoxypropylene glyceryl ether 0.1%, EDTA 0.01%;

Embodiment 2

[0025] A glass light guide plate degreasing agent, comprising the following raw materials in mass fraction:

[0026] Propylene glycol methyl ether 39.79%, dimethyl succinate 50%, Pingpinga O-25 10%, polyoxyethylene polyoxypropylene stearyl ether 0.1%, polyoxypropylene glyceryl ether 0.1%, EDTA 0.01%;

Embodiment 3

[0028] A glass light guide plate degreasing agent, comprising the following raw materials in mass fraction:

[0029] Dipropylene glycol methyl ether 49.79%, butyl acetate 40%, mesitylene 10%, polyoxyethylene polyoxypropylene stearyl ether 0.1%, polyoxypropylene polyoxyethylene glyceryl ether 0.1%, EDTA 0.01%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com