Method using rose fermentation to prepare fragrant rose wine and wine prepared by method

A rose and wine technology, applied in the field of wine, can solve the problems of soft and natural fragrance, which cannot be reflected, and the aroma component of wine cannot be harmoniously blended with rose fragrance, so as to achieve the effect of coordinated and soft wine body structure, delicate and round taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

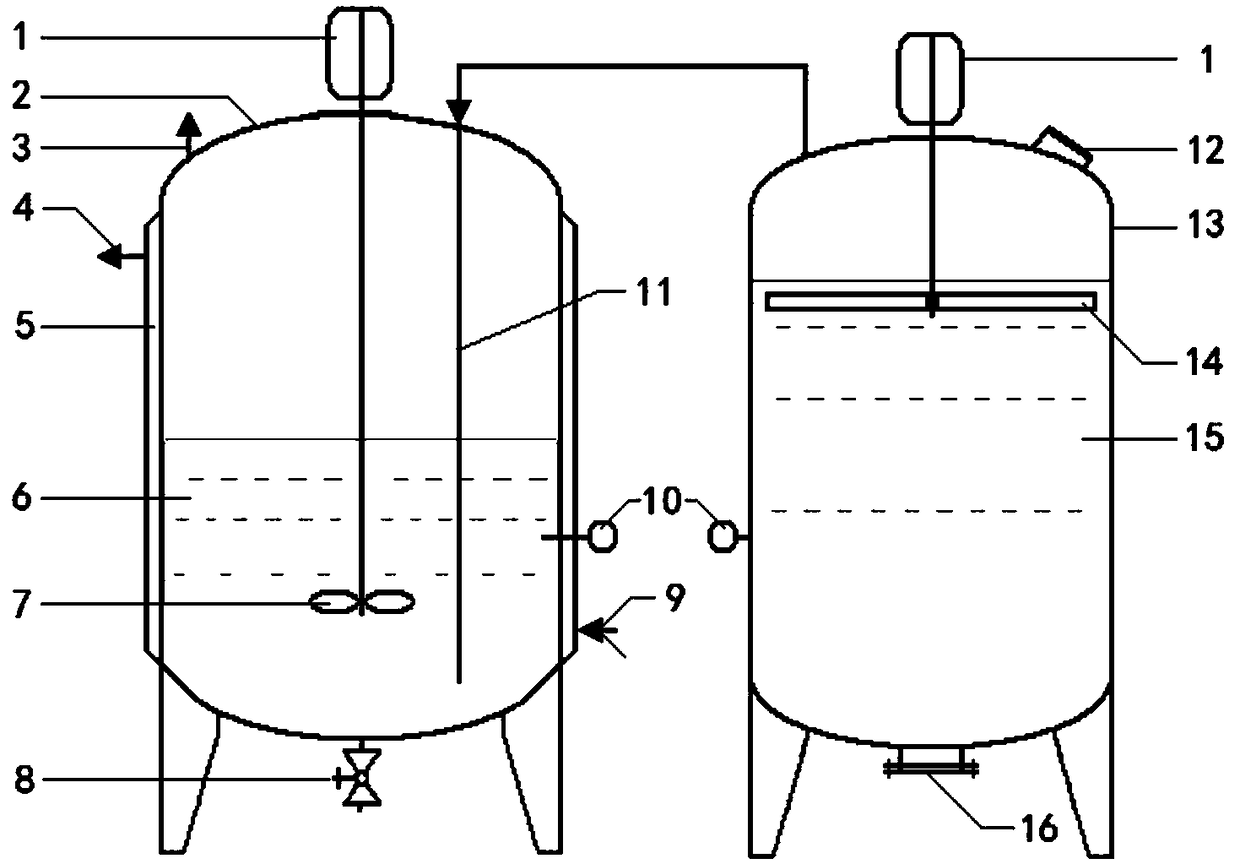

Image

Examples

Embodiment 1

[0045] 1. The roses harvested in the early morning of the day were quickly transported to the factory for processing. The roses and fresh grapes containing 20% refraction sugar were mixed and beaten at a weight ratio of 1:3 to make a fermented liquid with a refraction sugar content of 15%. , the weight ratio of the fermented liquid to the red wine to be aromatized is 1:3.

[0046] 2. Send the fermented liquid containing roses into the fermenter, add 0.2ml / L activated wine yeast liquid (the bacterial concentration is 4×10 7 pieces / ml. ), carry out alcoholic fermentation in a sealed fermenter, and the fermentation temperature is controlled at 20°C. During the fermentation process, the floating rose dregs and grape skin residues are stirred into the fermentation liquid by a stirring paddle, and the speed of the scum stirring paddle is 5rpm.

[0047] 3. A large amount of carbon dioxide produced by the alcoholic fermentation of the fermented liquid strips and separates the aroma...

Embodiment 2

[0051] 1. The roses harvested in the early morning of the day were quickly transported to the factory for processing. The roses were mixed with roses and white sugar at a ratio of 1:2, refined, put into barrels, and stored at room temperature for 2 months to obtain rose sauce. During fermentation, the rose sauce and water are mixed in a weight ratio of 1:2 to form a fermented liquid with a refraction sugar content of 23%, and the weight ratio of the fermented liquid to the white wine to be aromatized is 1:5.

[0052] 2. Send the fermented liquid containing roses into the fermenter, add 0.3ml / L activated wine yeast liquid (the bacterial concentration is 7×10 7 pieces / ml. ), carry out alcoholic fermentation in a sealed fermenter, and the fermentation temperature is controlled at 25° C. During the fermentation process, the floating roses are stirred into the fermented liquid by a stirring paddle, and the rotating speed of the scum stirring paddle is 10 rpm.

[0053] 3. The carbo...

Embodiment 3

[0057] 1. The roses harvested in the early morning of the day were quickly transported to the factory, sealed in plastic bags, frozen and stored at -20°C, and processed. 3 in a weight ratio of mixing and beating to make a fermented liquid with a refraction sugar content of 18%, and the weight ratio of the fermented liquid to the red wine to be aromatized is 1:3.

[0058] 2. Send the fermented liquid containing roses into the fermenter, add 0.5ml / L activated wine yeast liquid (the bacterial concentration is 9×10 7 pieces / ml. ), carry out alcoholic fermentation in a sealed fermenter, and the fermentation temperature is controlled at 30°C. During the fermentation process, the floating rose dregs are stirred into the fermentation broth by a stirring paddle, and the stirring paddle speed is 20rpm.

[0059] 3. A large amount of carbon dioxide produced by the alcoholic fermentation of the fermented liquid will strip out the aroma components of roses dissolved or dispersed in the fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com