Method for increasing content of astaxanthin in haematococcus pluvialis

A technology of Haematococcus pluvialis and astaxanthin, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high price and harmful substance pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

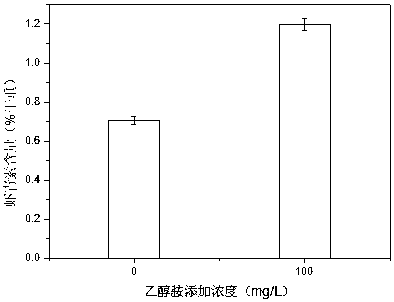

[0030] A columnar glass photobioreactor (height 50 cm, inner diameter 6 cm) and BG11 medium were used for autotrophic culture indoors to obtain the culture solution of Haematococcus pluvialis in the swimming stage. The algal species is Haematococcus pluvialis, which comes from the freshwater algae species bank of the Institute of Hydrobiology, Chinese Academy of Sciences, number 712. Astaxanthin induction was performed in the same reactor, and the culture medium was diluted with nitrogen-deficient BG11 medium so that the initial cell concentration in the induction phase was 0.2 g (dry weight) / L. When preparing the medium, MEA was added to a final concentration of 100 mg / L, and the medium was sterilized at 121 °C and 0.1 MPa for 20 minutes, and then diluted after cooling. Aeration stones commonly used in this field (pore size 30-60 μm) are used for aeration and mixing, and 8 LED light bars provide a light intensity of 200 μmol / (m 2 s) white light illumination. Use an air cond...

Embodiment 2

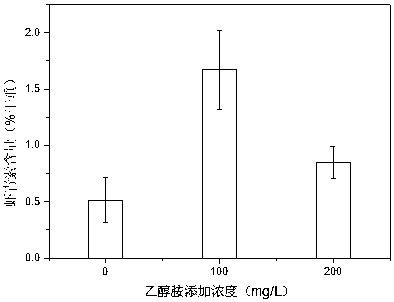

[0034] Others are the same as in Example 1, except that MEA is added to the culture solution of Haematococcus pluvialis to a final concentration of 200 mg / L.

[0035] MEA with a final concentration of 200 mg / L was added to the culture medium of Haematococcus pluvialis, and the batch induction culture was carried out for 8 days. The same microalgae were cultured under the same culture conditions, except that MEA was not added. It took 12 days for the cells to turn red completely, and the astaxanthin content accounted for 0.52% of the dry weight of the cells. In comparison, the astaxanthin content increased by 63 % after adding 200 mg / LMEA. Such as figure 1 shown.

[0036] MEA at a final concentration of 200 mg / L was added to the culture medium of Haematococcus pluvialis, and the batch induction culture was carried out for 8 days, and the cell concentration was 0.170 g (dry weight) / L; while using the same reactor and the same culture conditions The same microalgae were cultu...

Embodiment 3

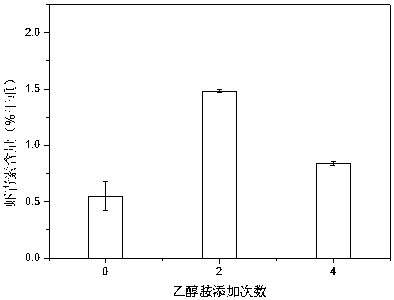

[0038] Others are the same as in Example 1, the difference is the source of Haematococcus pluvialis culture solution and the way of adding ethanolamine in the induction stage. Specifically, a closed columnar glass photobioreactor (height 50 cm, inner diameter 6 cm) and BG11 medium plus 1 g / L sodium zirconate was used as the medium for mixed culture to obtain the swimming stage of P. Coccus culture medium; Astaxanthin was induced in the same reactor, and the culture medium was diluted with nitrogen-deficient BG11 medium so that the initial cell concentration in the induction phase was 0.2 g (dry weight) / L. On the first day and the fourth day of culture, 50 mg / L MEA was added to the final concentration of 100 mg / L, and the added MEA solution was sterilized by ultraviolet disinfection.

[0039] Add twice 50 mg / L to the final concentration of 100 mg / L of MEA in the Haematococcus pluvialis culture medium, batch induction culture for 8 days, the ratio of astaxanthin to cell dry weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com