Preparation method of infrared camouflage fabric

A technology of infrared camouflage and fabric, which is applied in the field of preparation of infrared camouflage fabrics, can solve problems such as difficult to camouflage all infrared bands, poor hand feeling of infrared camouflage textiles, poor rubbing fastness, etc., and achieve excellent moisture permeability and excellent infrared camouflage effect , Improve the effect of bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

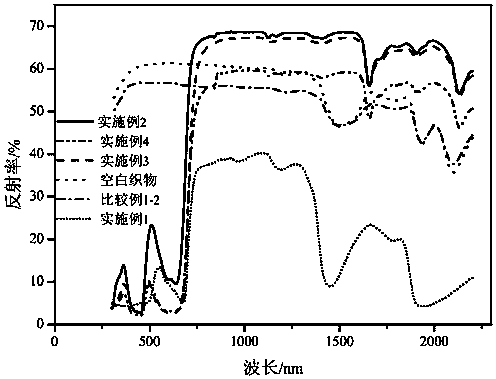

Image

Examples

Embodiment 1

[0023] (1) Zinc acetate dihydrate is dissolved in ethylene glycol monomethyl ether, and preparation concentration is the zinc acetate solution of 0.3mol / L; Aluminum nitrate is added in the above-mentioned solution, and the mol ratio of aluminum ion and zinc ion is 1: 10. After complete dissolution, add ethanolamine solution dropwise until the pH of the solution is 6.5, stir in a water bath at 60°C for 4 hours, and then let it stand for 24 hours to obtain the aluminum-doped zinc oxide sol;

[0024] (2) Set the molecular weight to 1.5×10 4 , the degree of deacetylation is that the chitosan of 80% is dissolved in the solute mass fraction 1% acetic acid solution, prepares the chitosan solution of mass fraction 3%; Then the gained aluminum-doped zinc oxide sol in step (1) is added to above-mentioned shell In the polysan solution, the mass ratio of aluminum-doped zinc oxide sol to chitosan is 1:1, then add the cross-linking agent epichlorohydrin accounting for 0.5% of chitosan mass,...

Embodiment 2

[0040] (1) Dissolve zinc acetate dihydrate in isopropanol to prepare a zinc acetate solution with a concentration of 0.75mol / L; add aluminum chloride to the above solution, and the molar ratio of aluminum ions to zinc ions is 1:20, After completely dissolving, add the diethanolamine solution dropwise until the pH of the solution is 7.5, stir in a water bath at 75°C for 2 hours, and then let it stand for 48 hours to obtain the aluminum-doped zinc oxide sol;

[0041] (2) The molecular weight is 10×10 4 , the chitosan that deacetylation degree is 95% is dissolved in the solute mass fraction 3% acetic acid solution, prepares the chitosan solution of mass fraction 5%; Then the gained aluminum-doped zinc oxide sol in step (1) is added to above-mentioned shell In the polysan solution, the ratio of aluminum-doped zinc oxide sol to chitosan mass is 1:3, then add the cross-linking agent epichlorohydrin accounting for 1% of chitosan mass, and adjust the pH to 0.1mol / L NaOH solution. 4.5...

Embodiment 3

[0045] (1) Dissolve zinc acetate dihydrate in isopropanol to prepare a zinc acetate solution with a concentration of 0.6mol / L; add aluminum chloride to the above solution, and the molar ratio of aluminum ions to zinc ions is 1:15, After complete dissolution, add triethanolamine solution dropwise until the pH of the solution is 7.0, stir in a water bath at 70°C for 3 hours, and then let it stand for 36 hours to obtain the aluminum-doped zinc oxide sol;

[0046] (2) The molecular weight is 5×10 4 , the degree of deacetylation is that the chitosan of 90% is dissolved in the solute mass fraction 2% acetic acid solution, prepares the chitosan solution of mass fraction 4%; Then the gained aluminum-doped zinc oxide sol in step (1) is added to above-mentioned shell In the polysan solution, the mass ratio of aluminum-doped zinc oxide sol to chitosan is 1:2, then add the cross-linking agent epichlorohydrin accounting for 0.8% of chitosan mass, and adjust the pH to 0.1mol / L NaOH solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com